A kind of high-conductivity aluminum alloy wire and its preparation method

An aluminum alloy wire, high conductivity technology, applied in the field of wires, can solve the problems of poor mechanical strength, decreased conductivity, and increased strength of wires, and achieves the effects of improving conductivity, inhibiting grain growth, and inhibiting recrystallization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

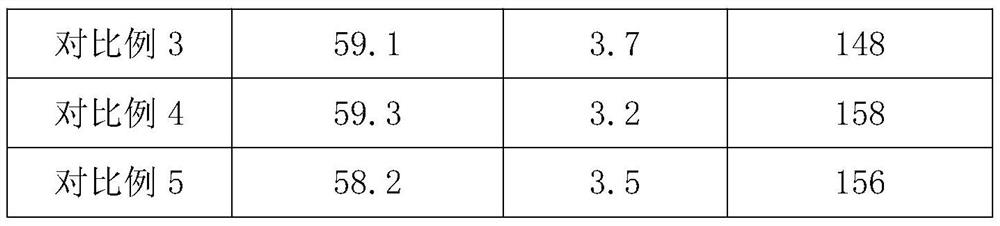

Examples

Embodiment 1

[0029] This embodiment relates to a high conductivity aluminum alloy wire, including an element of the following weight:

[0030] Mg was 1.15%, Si was 1.21%, Zr was 0.33%, Y was 0.25%, and CE was 0.06%, B was 0.41%, Cu was 0.61%, and the other impurity content was less than 0.3%, and the margin was Al.

[0031] This embodiment also provides a method for preparing high conductivity aluminum alloy wires, including the following steps:

[0032] (1) Select the aluminum block having a purity greater than 99%, and put the aluminum block into the constant temperature drying oven to dehumidify 45 minutes;

[0033] (2) Using a vacuum smelting furnace, the temperature of the vacuum moliner is controlled to 730 ° C, and the aluminum block is added, and the aluminum block is melted, after 20 minutes, add B, heat for 30 minutes to obtain a molten aluminum alloy liquid;

[0034] (3) Continue to add a slag, after the molten aluminum alloy fluid, mix the slag for 40 minutes, and the slag is silic...

Embodiment 2

[0041] This embodiment relates to a high conductivity aluminum alloy wire, including an element of the following weight percentage

[0042] Mg was 1.28%, Si was 1.35%, Zr was 0.42%, Y was 0.15%, CE was 0.33%, LA of 0.17%, B was 0.55%, CU was 0.85%, and the other impurity content was less than 0.3%, and the margin was Al.

[0043] This embodiment also provides a method for preparing high conductivity aluminum alloy wires, including the following steps:

[0044] (1) Select the aluminum block having a purity greater than 99%, and put the aluminum block into the constant temperature drying oven to dehumidification for 60 minutes;

[0045] (2) Use a vacuum smelting furnace to control the temperature of the vacuum molten furnace to 745 ° C, add aluminum block, so that the aluminum block is melted, after 30 minutes, add B, holding up for 40 minutes to obtain molten aluminum alloy;

[0046] (3) Continue to add a slag, after the molten aluminum alloy fluid is continued, mix the slag after ...

Embodiment 3

[0053] This embodiment relates to a high conductivity aluminum alloy wire, including an element of the following weight percentage

[0054] The Mg was 1.35%, Si was 1.35%, Zr was 0.33%, Y was 0.15%, CE of 0.25%, LA of 0.17%, B was 0.41%, Cu was 0.85%, and the other impurity content was less than 0.3%, and the balance was Al.

[0055] This embodiment also provides a method for preparing high conductivity aluminum alloy wires, including the following steps:

[0056] (1) Select the aluminum block having a purity greater than 99%, and put the aluminum block into the constant temperature drying oven to dehumidification for 60 minutes;

[0057] (2) Using a vacuum smelting furnace, the temperature of the vacuum smelting furnace is controlled to 745 ° C, and the aluminum block is added, and the aluminum block is melted, after 20 minutes, add B, holding for 40 minutes to obtain molten aluminum alloy;

[0058] (3) Continue to add a slag, after the molten aluminum alloy fluid, mix the slag f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com