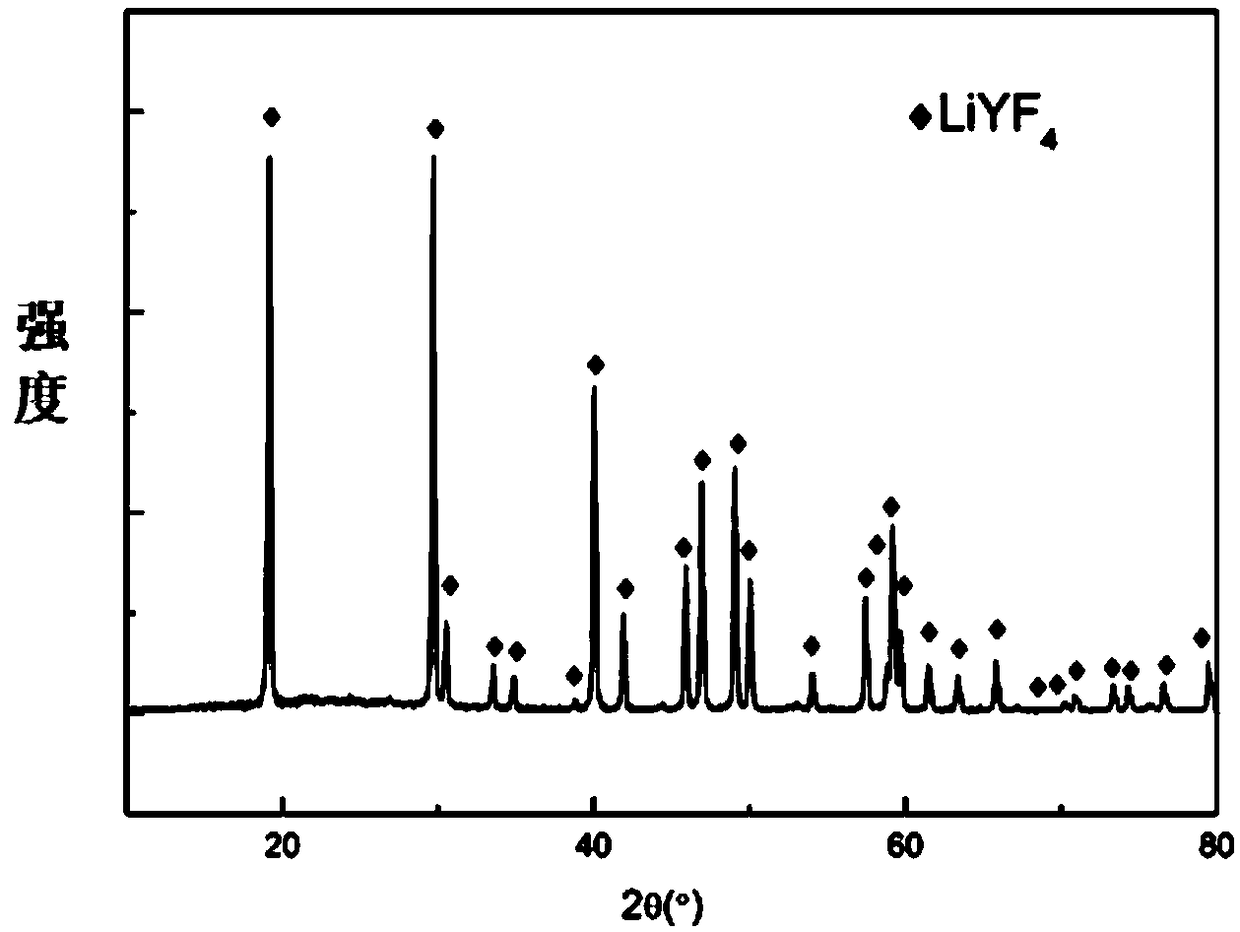

Yttrium lithium fluoride-doped scintillating microcrystal and preparation method and application thereof

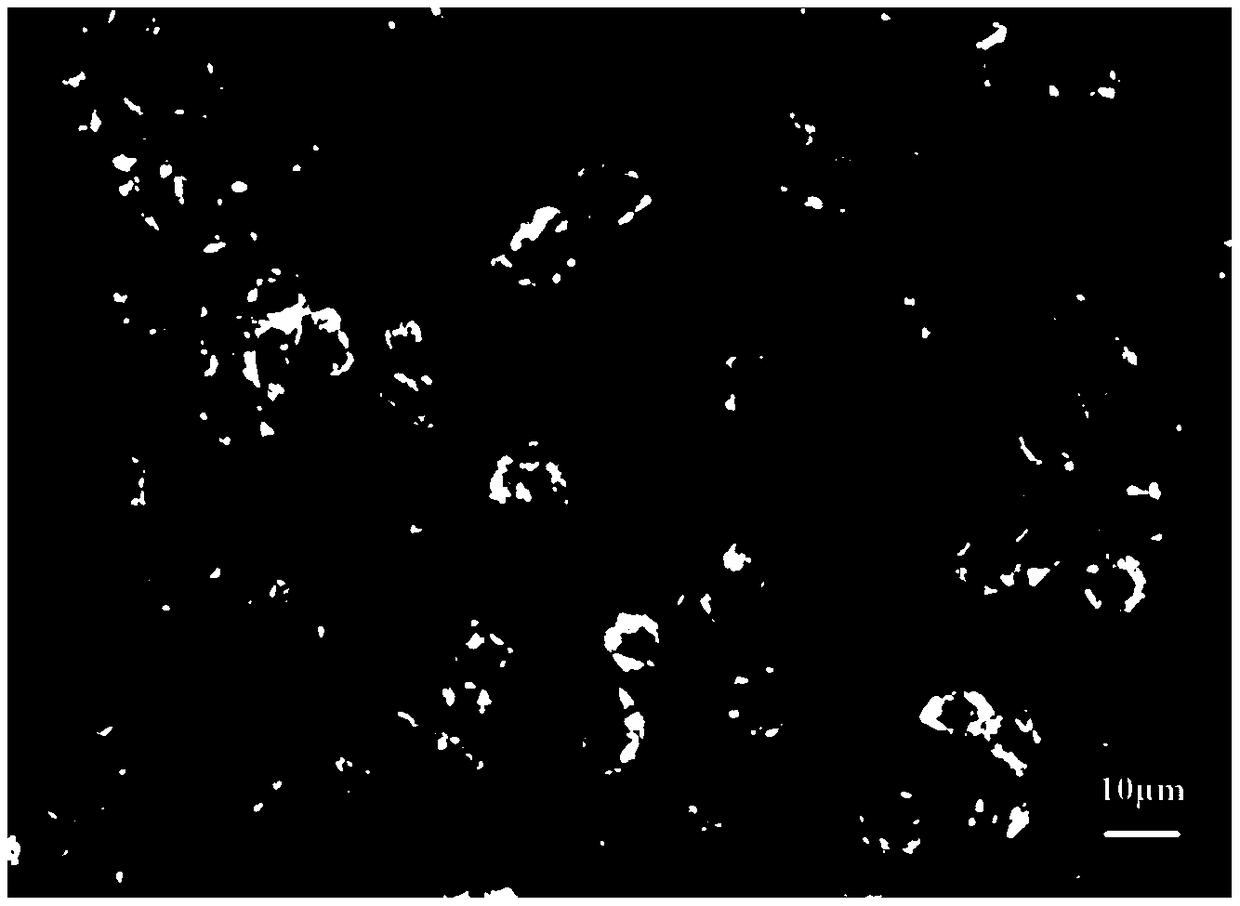

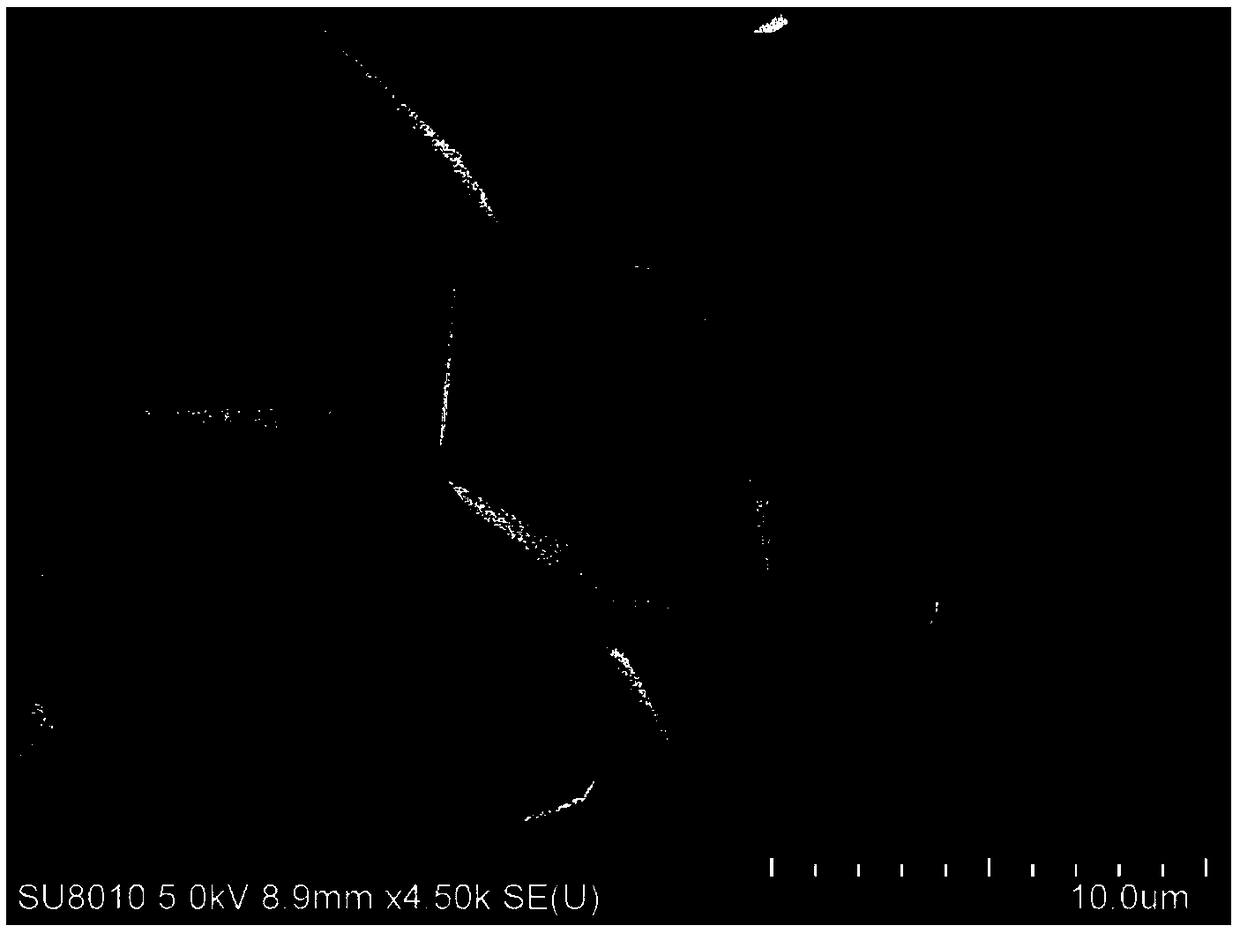

A technology of yttrium lithium fluoride and heteroyttrium fluoride is applied in the field of doped yttrium lithium fluoride scintillation crystallites and their preparation, which can solve the problems of limited mass production and harsh condition control, and achieve excellent scintillation performance and size. Uniform size and good crystallite transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] Weigh the following reaction materials: LiF, NH 4 F, Y (NO 3 ) 3 ·6H 2 O, Ce(NO 3 ) 3 ·6H 2 O, PrCl 3 , the quality of the raw material is according to the chemical formula LiCe 0.02 PR x Y 0.98-x f 4 The molar ratio of each atom in is weighed, where x=0.01. In LiF and NH 4 Add 10ml of distilled water to F, stir to form mixed solution M, the concentration of LiF in solution M is 1mol / L; then in Y(NO 3 ) 3 ·6H 2 O, Ce(NO 3 ) 3 ·6H 2 O and PrCl 3 Add 10ml of distilled water to the solution, stir and dissolve to form solution N, and Ce(NO 3 ) 3 The concentration of the concentration is 0.02mol / L; Adding mass fraction in solution N simultaneously is the complexing agent of 3.0% (complexing agent accounts for the mass fraction of reactant total mass), and wherein complexing agent is ethylenediaminetetraacetic acid; Then, The solution N containing the complexing agent is mixed with the mixed solution M to form the final mixed solution A, accompanied by vig...

Embodiment 2

[0084] Weigh the following reaction materials: LiF, NH 4 F, Y (NO 3 ) 3 ·6H 2 O, Ce(NO 3 ) 3 ·6H 2 O, PrCl 3 , the quality of the raw material is according to the chemical formula LiCe 0.02 PR x Y 0.98-x f 4 The molar ratio of each atom in is weighed, where x=0.02. In LiF and NH 4 Add 12ml of distilled water to F, stir to form mixed solution M, the concentration of LiF in solution M is 0.833mol / L; 3 ) 3 ·6H 2 O, Ce(NO 3 ) 3 ·6H 2 O and PrCl 3 Add 8ml of distilled water to the solution, stir and dissolve to form solution N, Ce(NO 3 ) 3 The concentration of is 0.025mol / L; Adding the complexing agent that mass fraction is 2.5% (complexing agent accounts for the mass fraction of reactant total mass) simultaneously in solution N, wherein complexing agent is sodium hexametaphosphate; Then, will The solution N containing the complexing agent is mixed with the mixed solution M to form the final mixed solution A, accompanied by vigorous stirring; moreover, the fully...

Embodiment 3

[0086] Weigh the following reaction materials: LiF, NH 4 F, Y (NO 3 ) 3 ·6H 2 O, Ce(NO 3 ) 3 ·6H 2 O, PrCl 3 , the quality of the raw material is according to the chemical formula LiCe 0.02 PR x Y 0.98-x f 4 The molar ratio of each atom in is weighed, where x=0.03. In LiF and NH 4 Add the distilled water of 14ml in F, stir to form mixed solution M, the concentration of LiF in the solution M is 0.714mol / L; Then in Y(NO 3 ) 3 ·6H 2 O, Ce(NO 3 ) 3 ·6H 2 O and PrCl 3 Add 6ml of distilled water to the solution, stir and dissolve to form solution N, Ce(NO 3 ) 3 The concentration of the concentration is 0.033mol / L; Add the complexing agent that mass fraction is 2.0% (complexing agent accounts for the mass fraction of reactant total mass) simultaneously in solution N, wherein complexing agent is aminotrimethylene phosphonic acid; Then , the solution N containing the complexing agent is mixed with the mixed solution M to form the final mixed solution A, accompanied ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com