Mixing system for conveying gypsum powder

A gypsum powder and mixing technology, which is applied in the direction of selling raw material supply devices, clay preparation devices, chemical instruments and methods, etc., can solve the problem of uneven cutting, and achieve the effects of simple structure, stable flow and high degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings. Similar parts in the figures are denoted by the same reference numerals. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

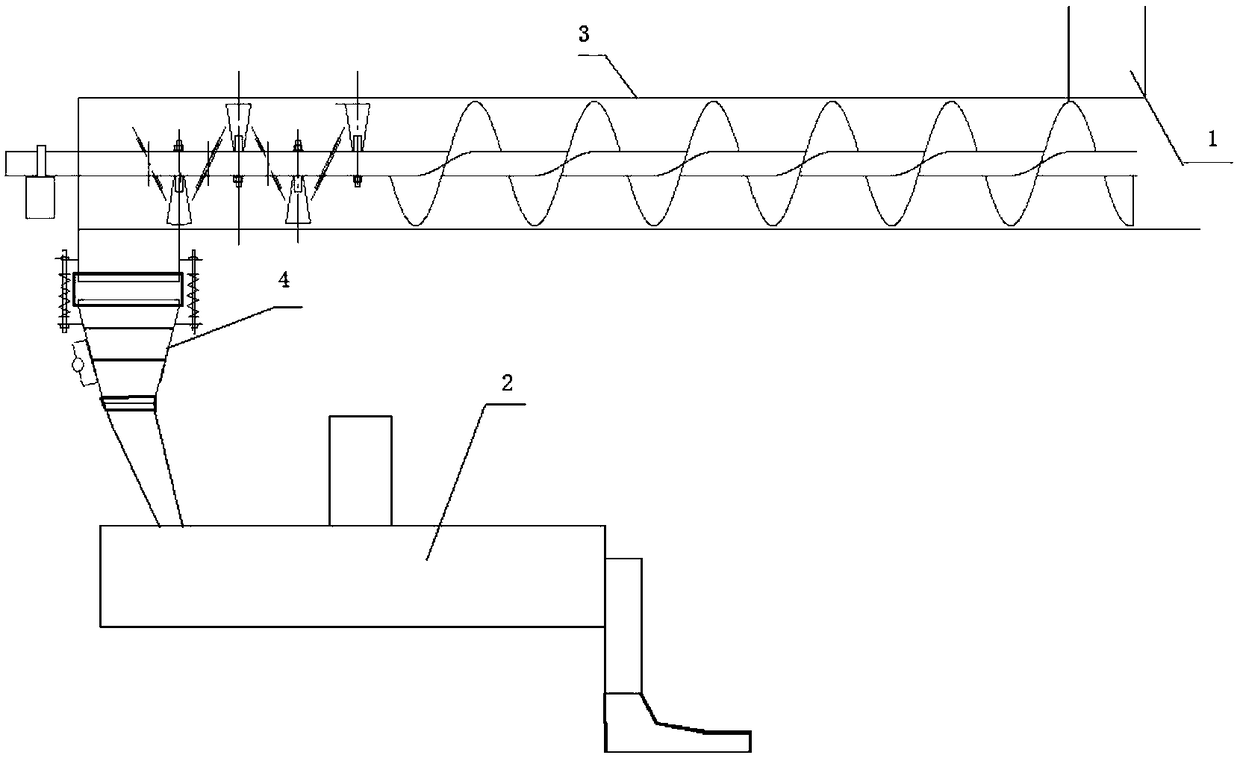

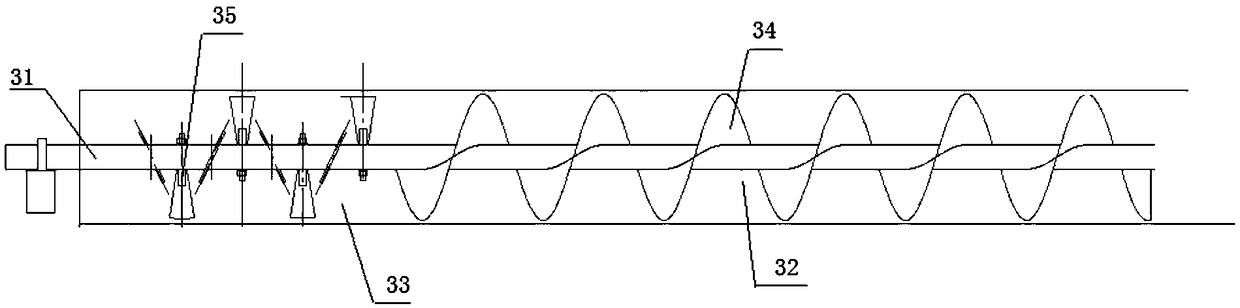

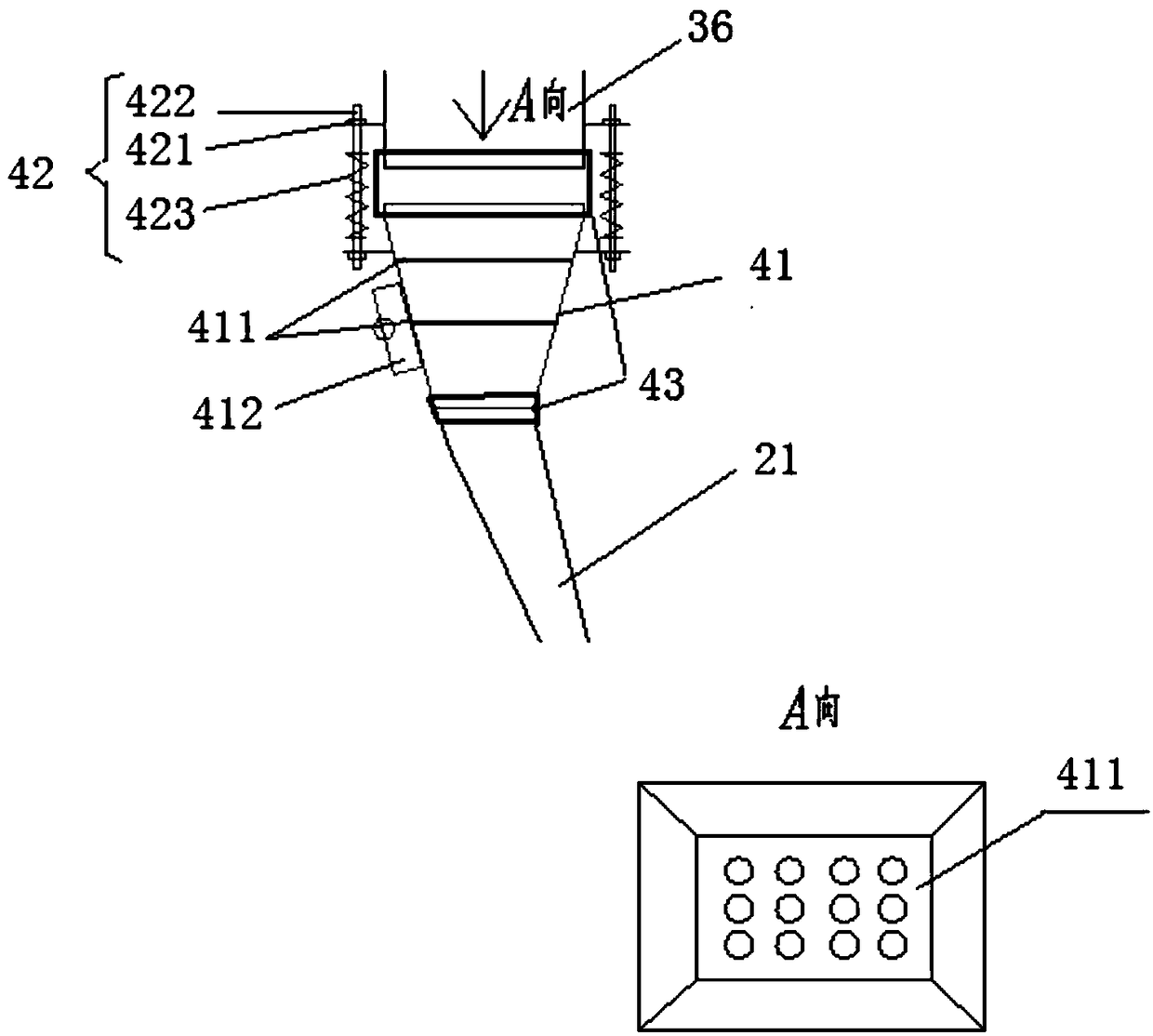

[0025] In one embodiment of the present invention, as figure 1 As shown, a mixing system for conveying gypsum powder is provided, which comprises a reamer 1 for conveying gypsum powder, a mixer 2 for mixing gypsum powder and other raw materials, and The gypsum powder output by the knife machine 1 breaks up into a stirring unit 3 with a small fluctuation amount, and the gypsum powder broken up by the stirring unit 3 is evenly transported to the conveying unit 4 of the mixer.

[0026] During the production process of gypsum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com