Automatic cutting saw machine

An automatic cutting and cutting saw technology, applied in circular saws, sawing equipment, wood processing appliances, etc., can solve the problems affecting the cutting effect, the uneven frequency of artificially pushing the board forward, and achieve the effect of smooth cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific embodiment:

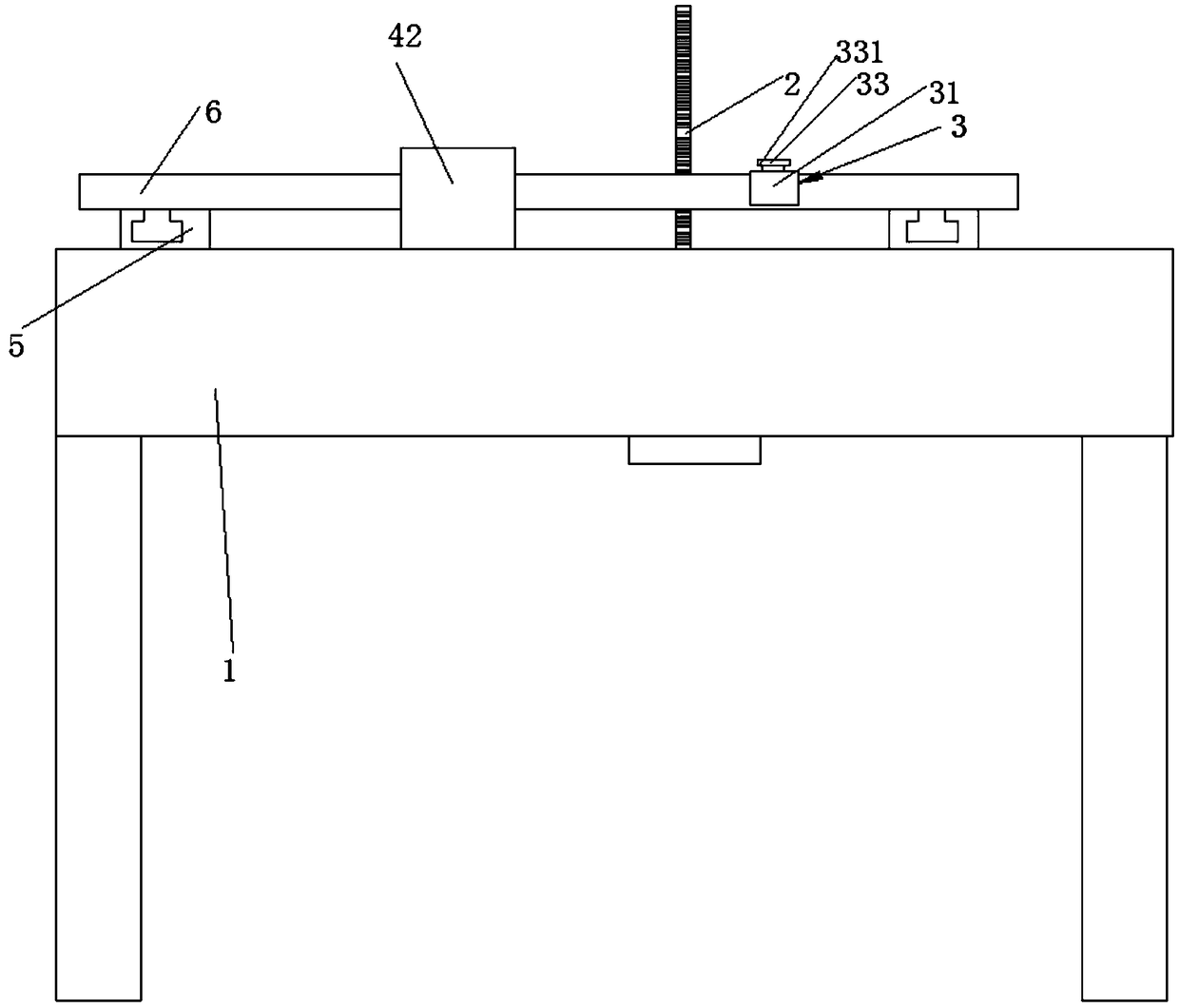

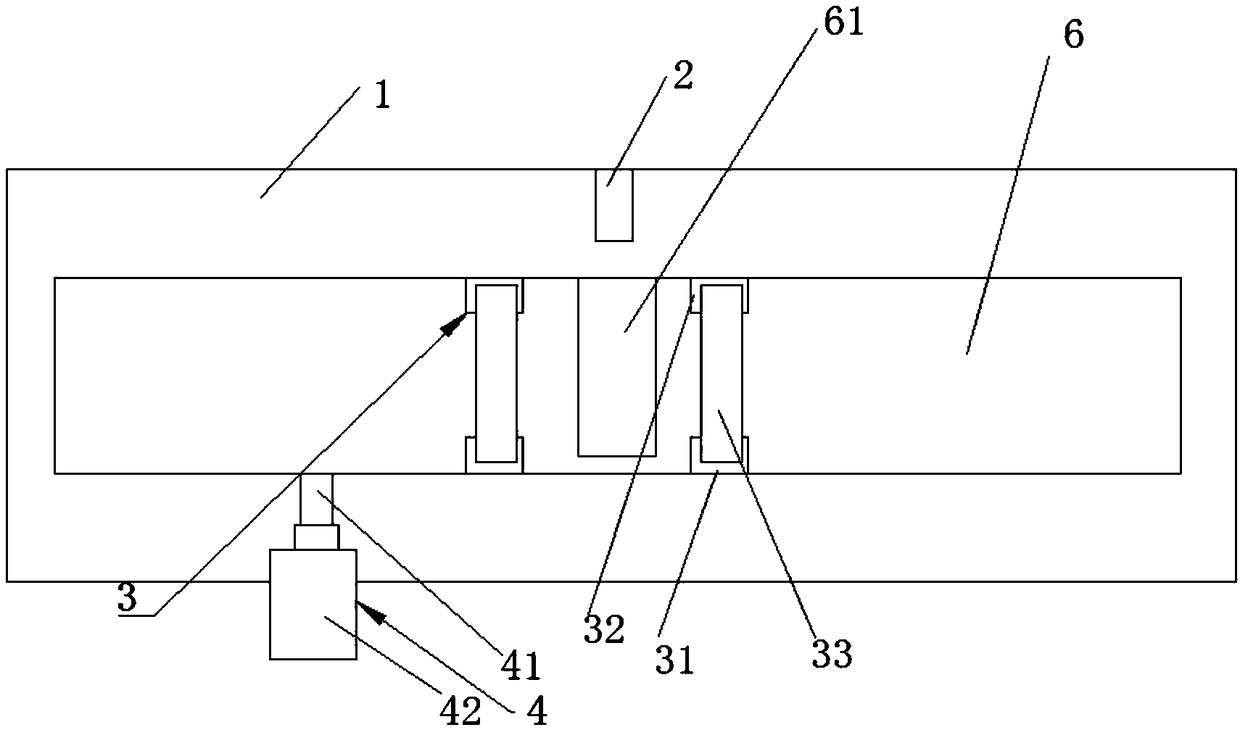

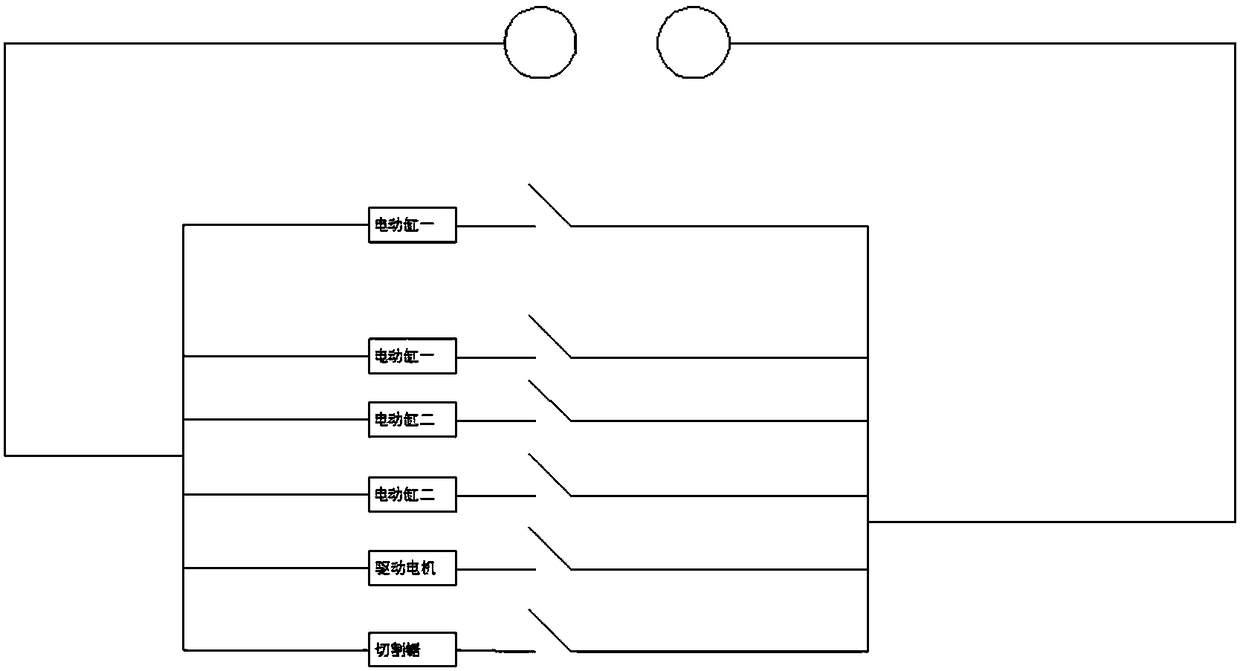

[0016] Such as Figure 1 to Figure 3 As shown, an automatic cutting saw 2 bed includes a cutting platform 1, a cutting saw 2, and a fixing device 3. The cutting saw 2 is arranged on the cutting platform 1, and also includes a propulsion device 4. The cutting platform 1 is provided with a guide rail 5, and the guide rail 5 is arranged at both ends of the cutting platform 1, and is arranged along the width direction of the cutting platform 1. A supporting plate 6 is arranged on the guide rail 5, and the two ends of the supporting plate 6 are slidingly connected with the guide rail 5 respectively. The position is provided with a gap 61, the gap 61 is used to cut the walking path, the propulsion device 4 includes a screw rod 41 and a drive motor 42, the screw rod 41 runs through the supporting plate 6, the screw rod 41 is threaded with the supporting plate 6, and the end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com