Vibrated grinding process method for materials difficult to machine

A processing method and difficult-to-process technology, which is applied in the field of oscillating grinding of difficult-to-machine materials, can solve the problems of low grinding efficiency, negative effects, and poor grinding economy, so as to achieve improved grinding wheel life, high surface integrity, and avoid Effect of Grinding Burn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

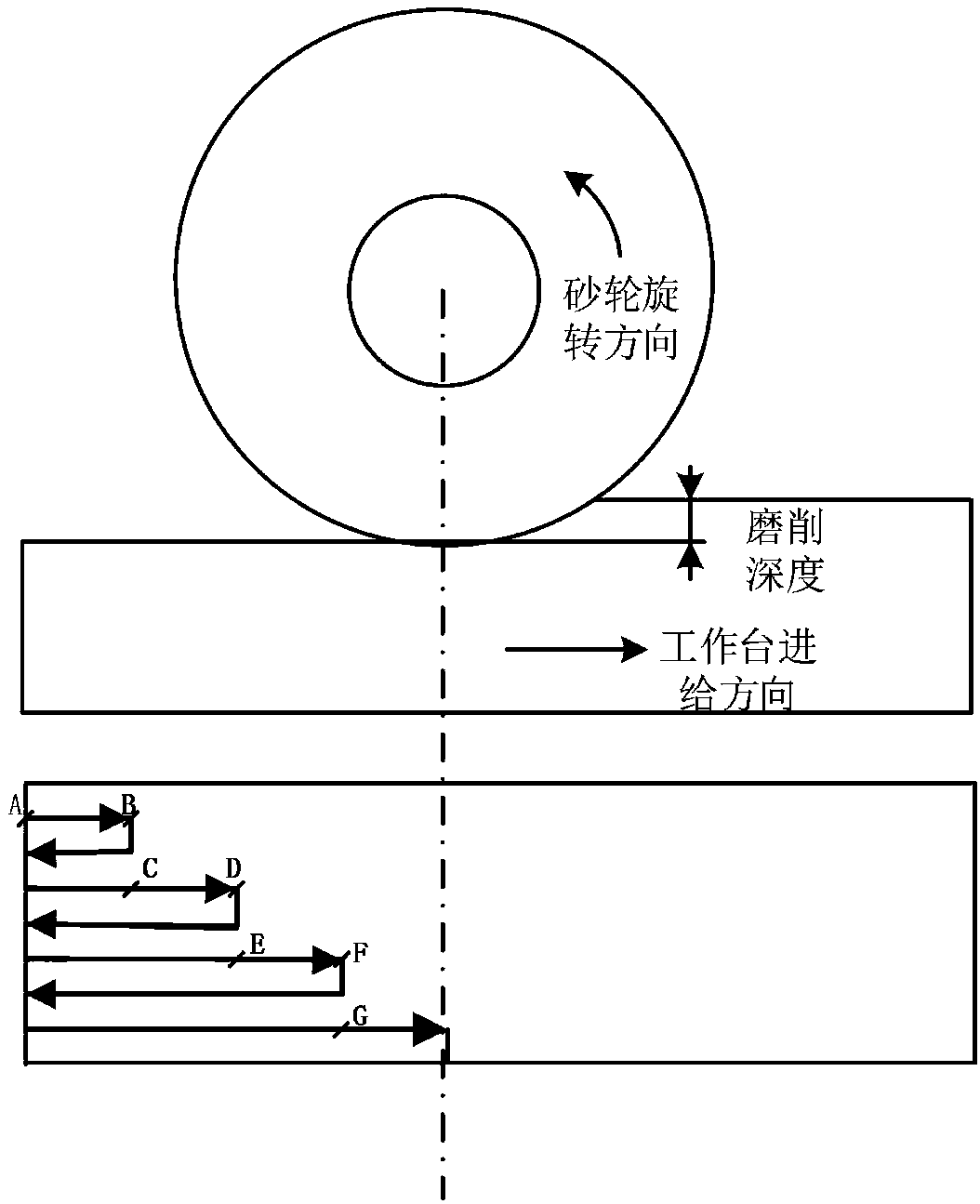

[0028] A method for oscillating grinding of difficult-to-machine materials, the specific steps are as follows:

[0029] Step 1: Determine the process parameters of slow-feed deep-cut grinding

[0030] The selected workpiece material is nickel-based superalloy GH4169, the coolant is water-based emulsion, the grinding wheel is corundum grinding wheel, the diameter of the grinding wheel is 400mm, and the grinding machine is a high-speed CNC grinding machine. The grinding test site is as follows: figure 1 shown. The test process includes:

[0031] (1) Clean the workpiece;

[0032] (2) Clamping: the nickel-based high-temperature alloy workpiece is clamped on the CNC grinding machine workbench by a clamp;

[0033] (3) Dressing of the grinding wheel: the surface of the corundum grinding wheel is trimmed with a single-grain diamond dressing pen. The trimming amount is 0.2mm.

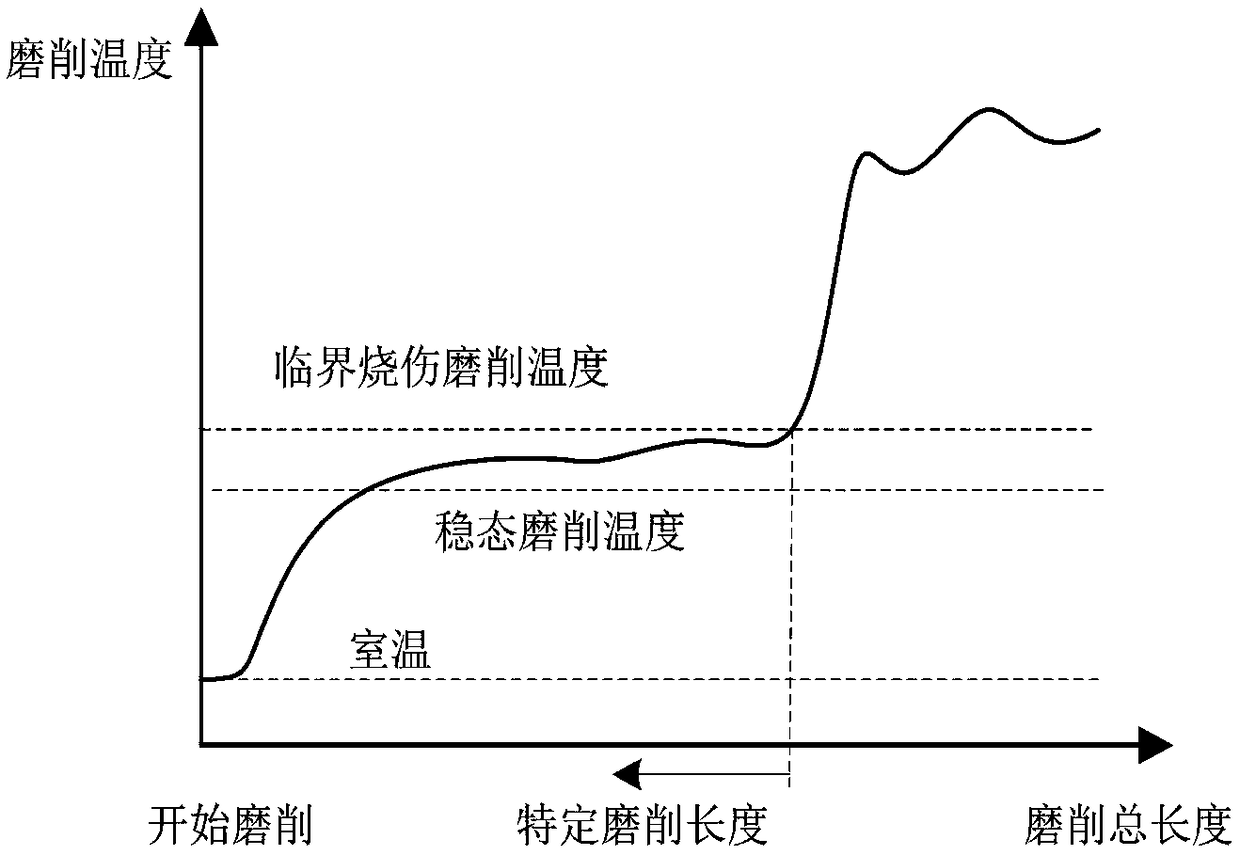

[0034] A set of process parameters for the slow-feed grinding burn of nickel-based superalloys are selec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Surface roughness value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com