Aeration mixing device for new energy silicone foam

A technology of foaming silica gel and mixing device, applied in mixer, transportation and packaging, dissolving and other directions, can solve the problems of too simple structure, insufficient function, uneven gas discharge, etc., to shorten working time, better effect and thorough stirring Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

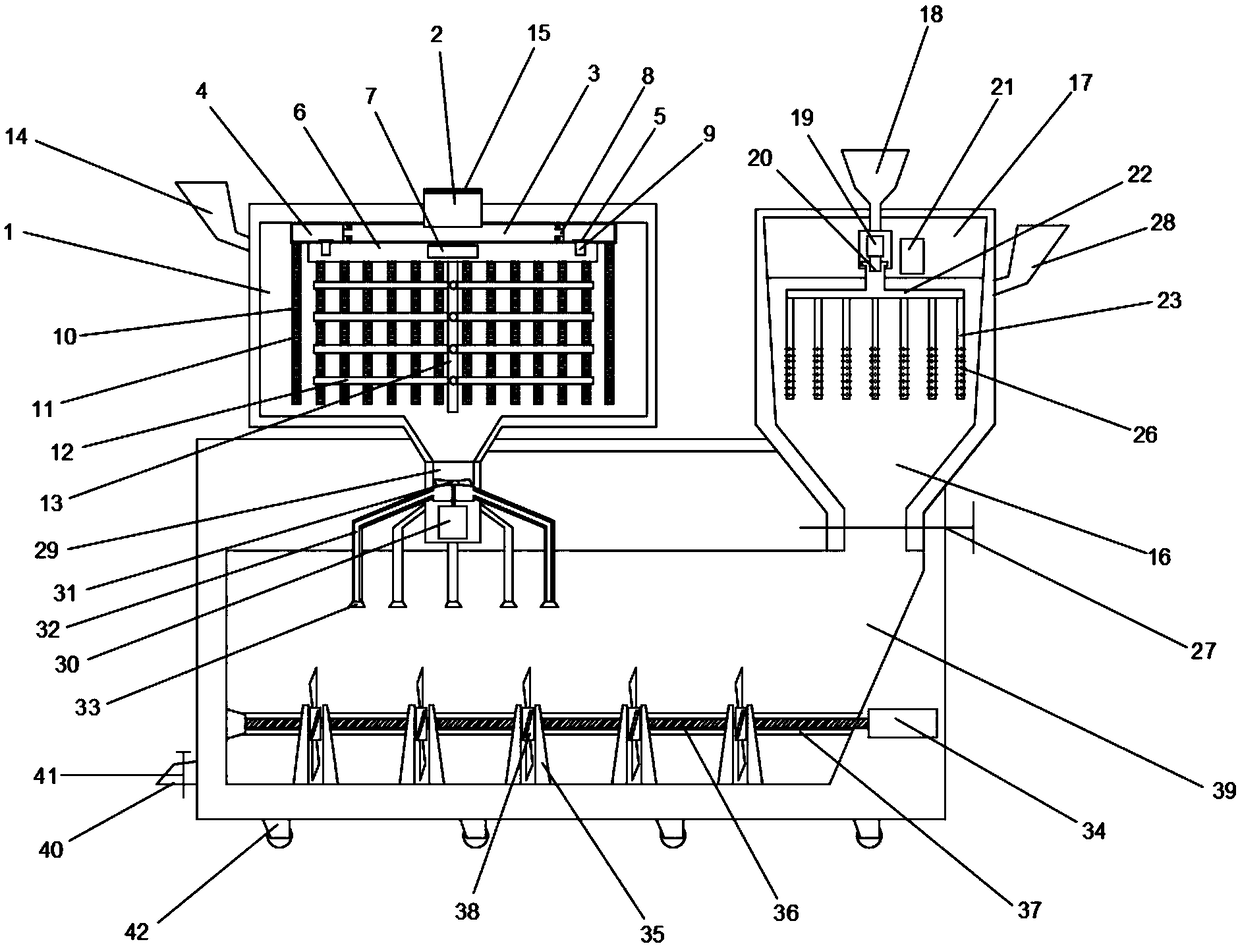

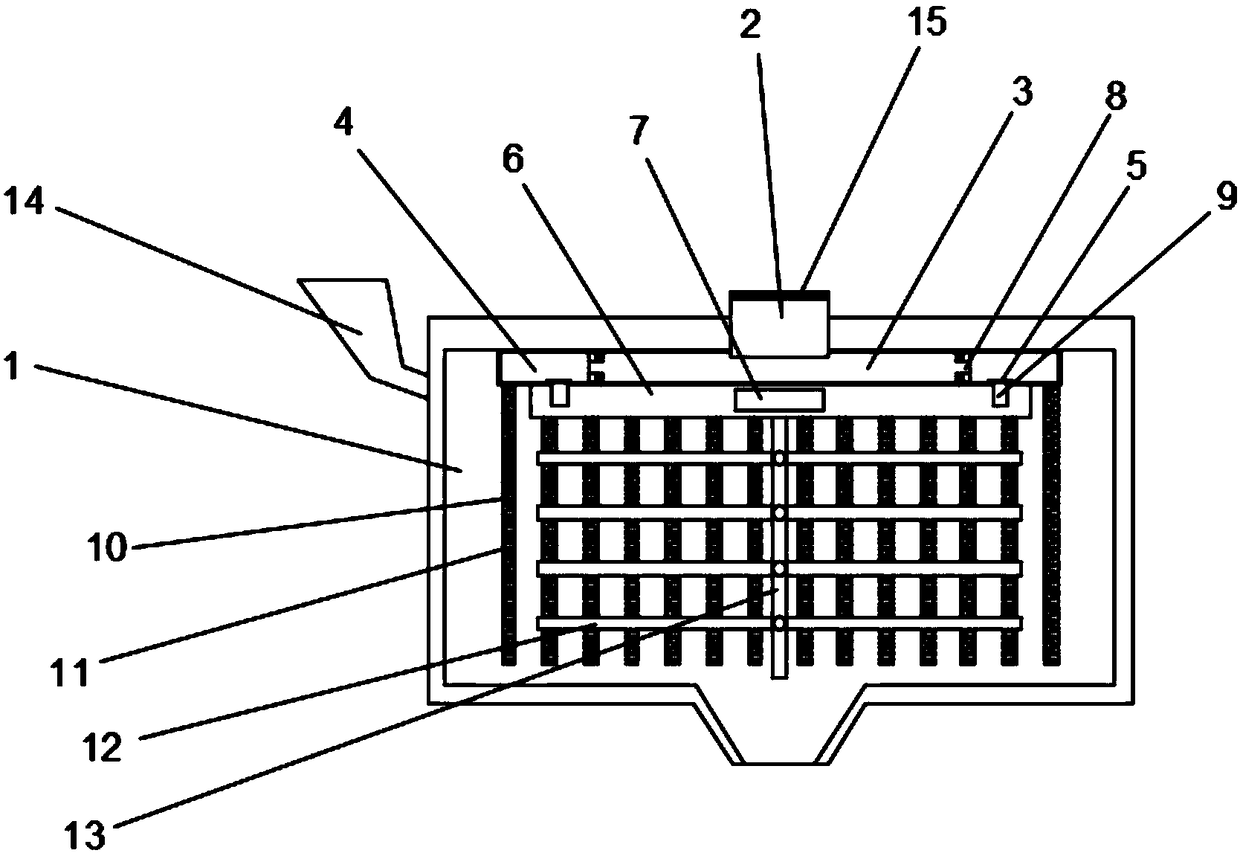

[0029] Embodiment 1: as Figure 1-7 As shown, a new energy foamed silica gel aeration mixing device includes a first cabin 1, a second cabin 16 and a mixing cabin 39, and the first cabin 1 and the second cabin 16 are located in the mixing cabin 39, the bottom of the first cabin body 1 and the second cabin body 16 are connected with the top of the mixing cabin 39;

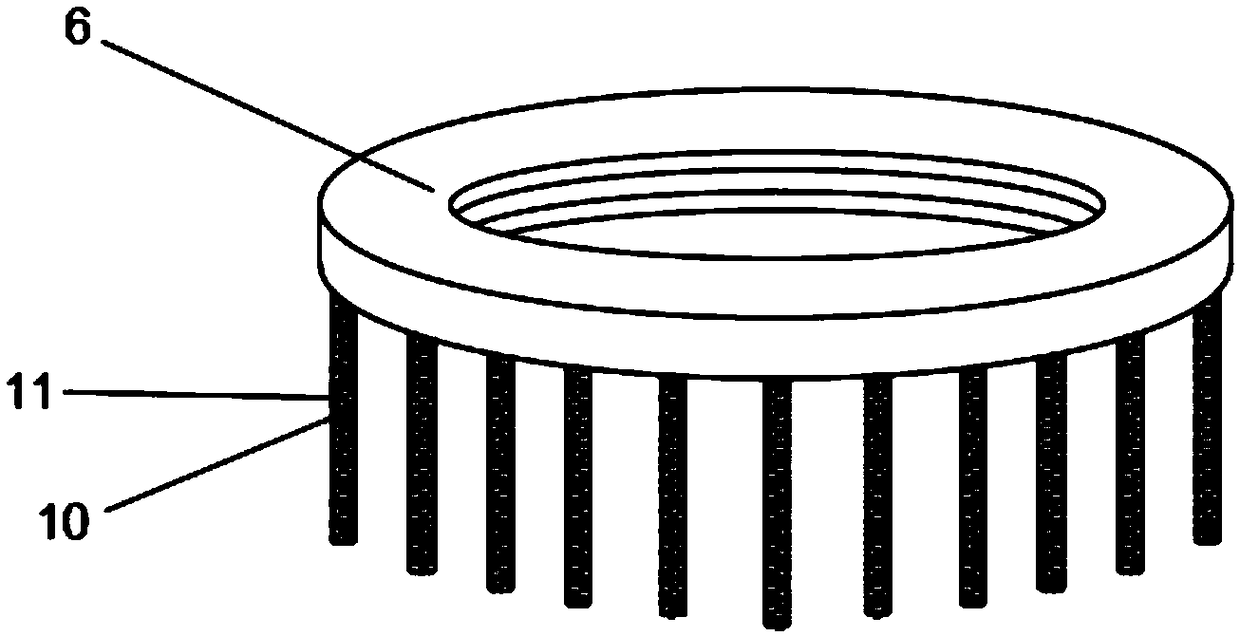

[0030] The top of the inner cavity of the first cabin body 1 is fixedly connected with an air chamber 3, the top of the air chamber 3 is fixedly installed with a fan 2, and the top of the fan 2 is fixedly installed with a dust-proof net 15, and the wind chamber 3 The bottom of the air chamber 3 is fixedly connected with a bracket 6, and the side wall of the air chamber 3 is fixedly connected with a number of air outlets 8, and the outer side of the air chamber 3 is movably socketed with a ring chamber turntable 4, and the wind chamber 3 and the ring chamber turntable 4 are sealed, the circle cavity turntable 4 is l...

Embodiment 2

[0033] Embodiment 2: as Figure 1-8 As shown, a new energy foamed silica gel aeration mixing device includes a first cabin 1, a second cabin 16 and a mixing cabin 39, and the first cabin 1 and the second cabin 16 are located in the mixing cabin 39, the bottom of the first cabin body 1 and the second cabin body 16 all communicate with the top of the mixing cabin 39, and the bottom of the mixing cabin 39 is fixedly equipped with a moving wheel 42, and the moving wheel 42 is at least provided with Four groups;

[0034] The top of the inner cavity of the first cabin body 1 is fixedly connected with an air chamber 3, the top of the air chamber 3 is fixedly installed with a fan 2, and the top of the fan 2 is fixedly installed with a dust-proof net 15, and the wind chamber 3 The bottom of the air chamber 3 is fixedly connected with a bracket 6, and the side wall of the air chamber 3 is fixedly connected with a number of air outlets 8, and the outer side of the air chamber 3 is movab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com