White smoke removal device for smoke plume

A smoke plume and smoke chamber technology, which is applied in the field of environmental protection equipment, can solve the problems of high dust concentration of flue gas and water content of flue gas, the effect of condensation precipitation of flue gas and the effect of dewhitening of flue gas need to be strengthened, etc. Condensation efficiency, the effect of reducing the moisture content of flue gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

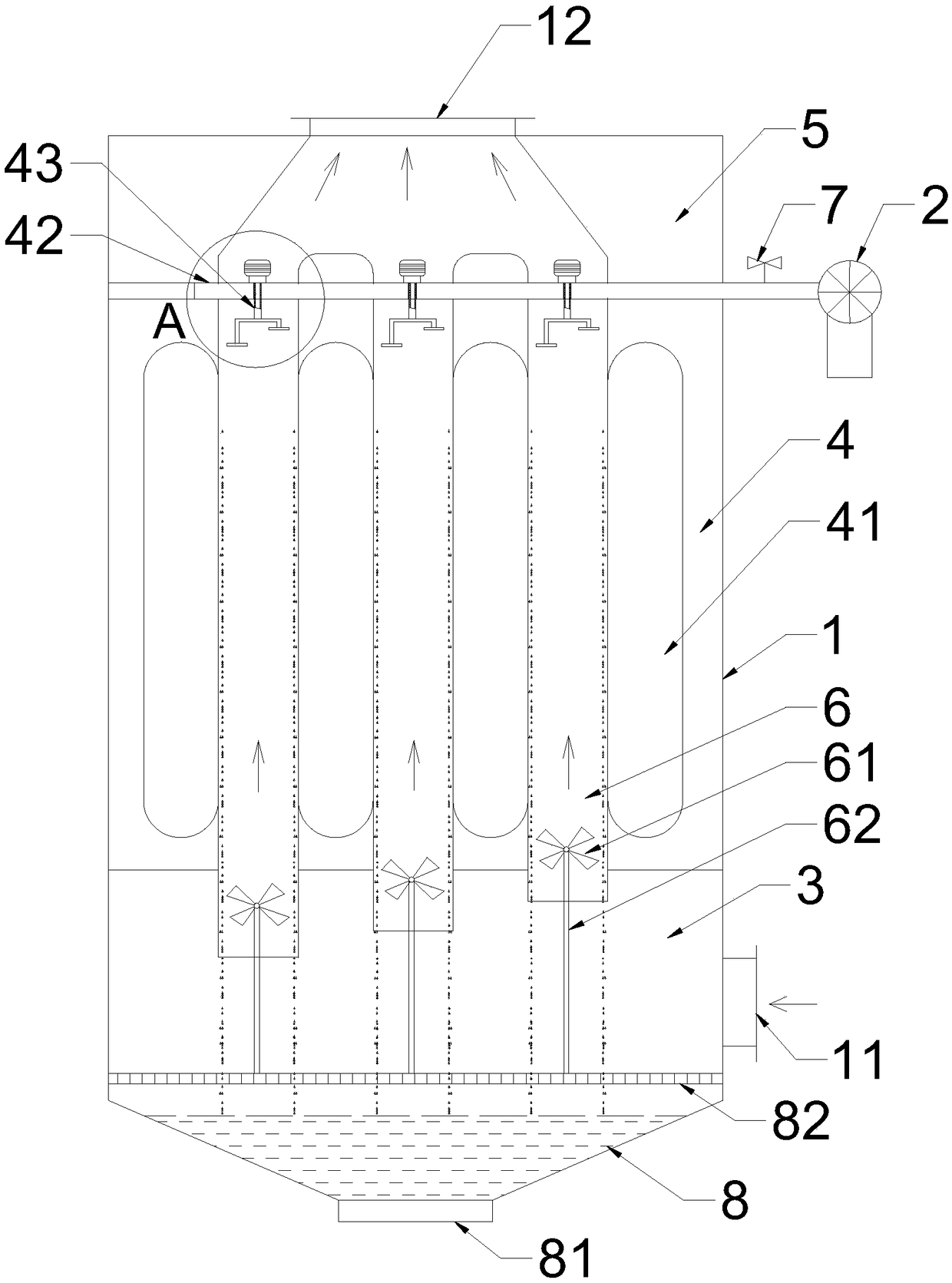

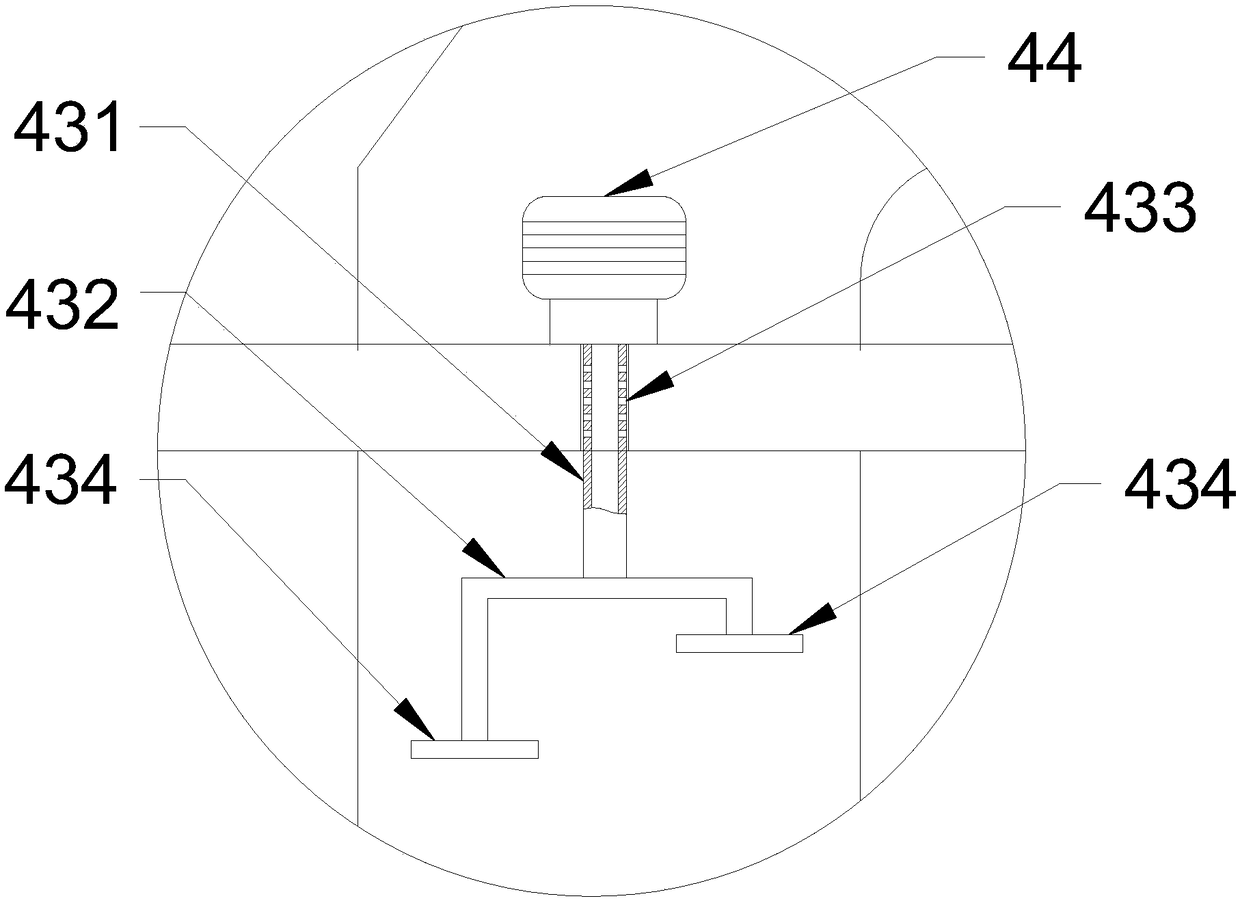

[0022] like figure 1 As shown, a kind of plume de-whitening device comprises a plume separation tower 1, the lower side of the plume separation tower 1 is provided with a flue gas inlet 11, the flue gas inlet 11 is connected to the gas outlet of the desulfurization tower, and the plume separation tower 1 There is a flue gas outlet 12 on the top, and the flue gas outlet 12 is connected to the flue gas reheater; the smoke plume precipitation tower 1 is provided with a smoke inlet chamber 3, a condensation chamber 4 and a smoke exhaust chamber 5 from bottom to top, and the smoke inlet chamber 3 is connected The flue gas inlet 11, the smoke exhaust chamber 5 is connected to the flue gas outlet 12; several condensation tubes 41 are arranged vertically in the condensation chamber 4, and cooling water is passed through the condensation tubes 41; There are several flue gas flow channels 6, the lower end of the flue gas flow channel 6 extends into the smoke inlet chamber 3, the upper e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com