Mechanical automatic fire fighting cabinet based on air cooling

A cabinet and machinery technology, applied in the field of mechanical automatic fire-fighting cabinets, can solve the problem of high fire risk, reduce fire risk, improve poor fan heat, and speed up air flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

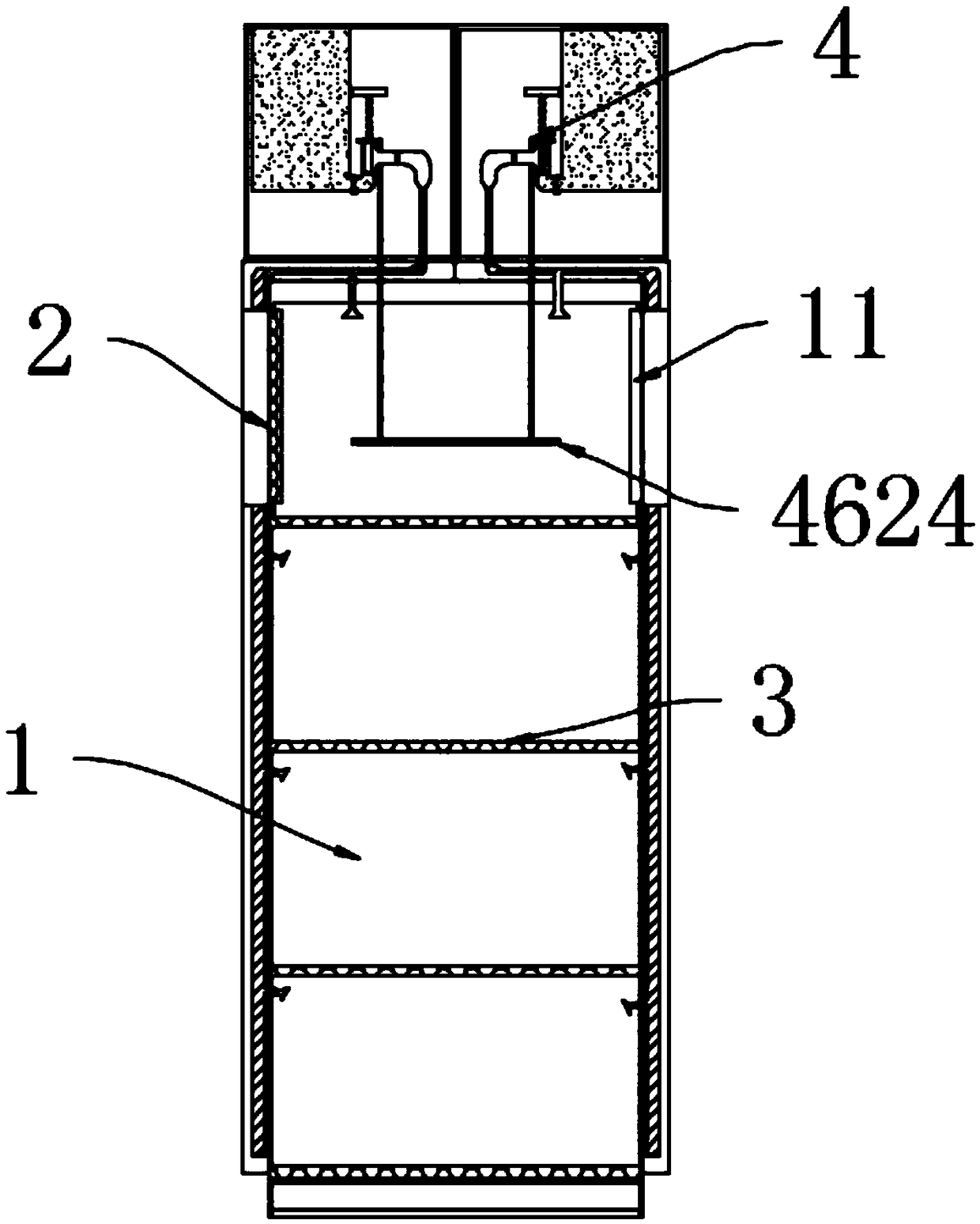

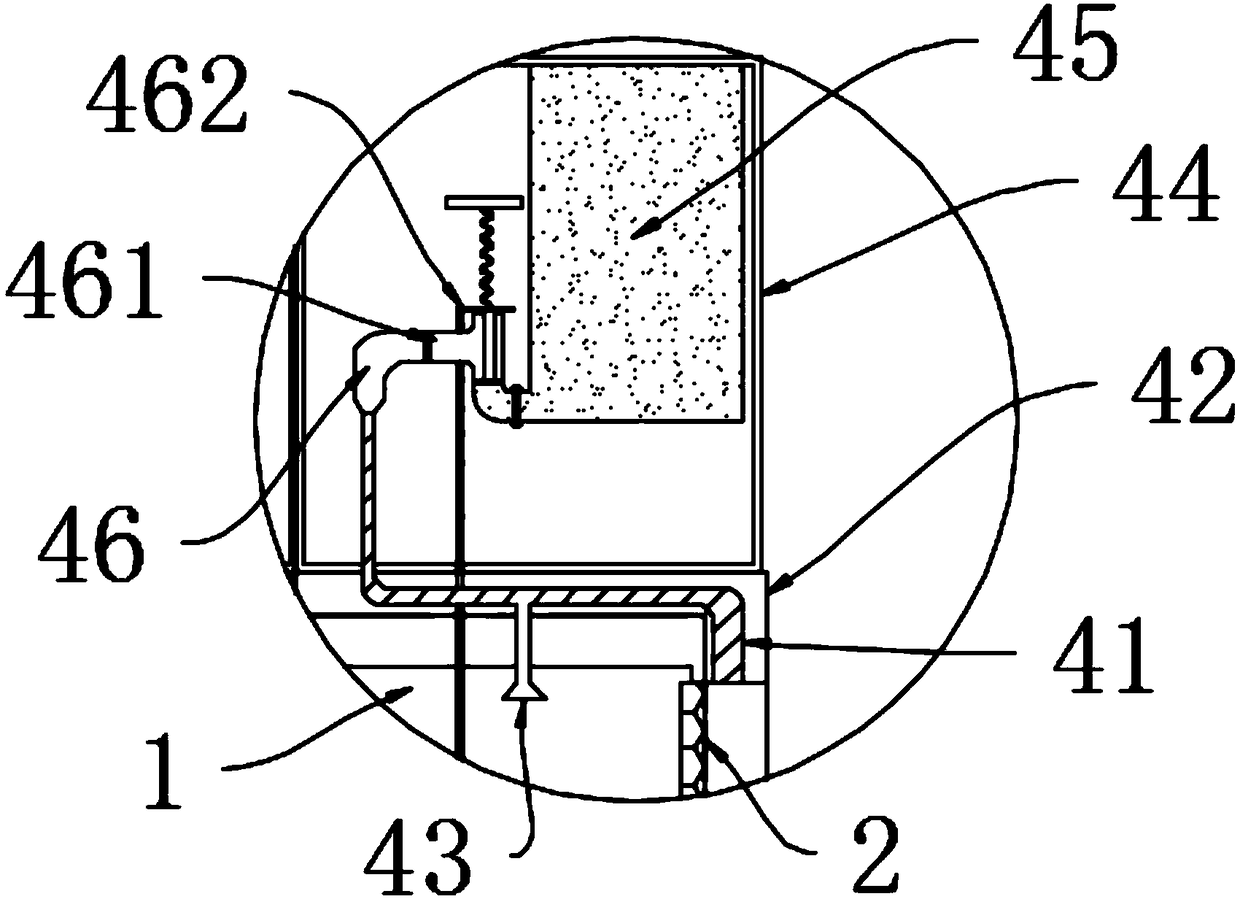

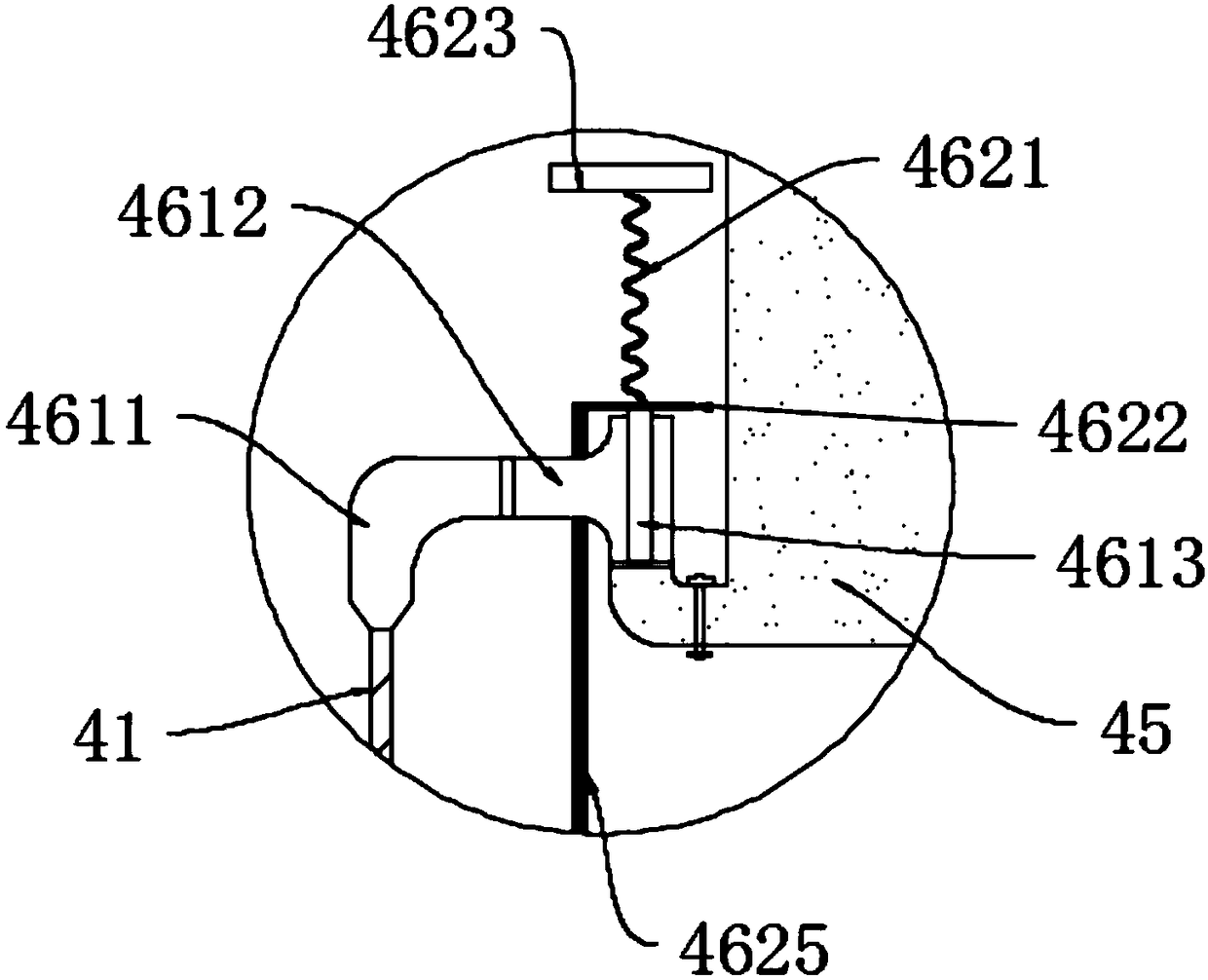

[0031] An air-cooled mechanical automatic fire-fighting cabinet provided by a preferred embodiment of the present invention includes a cabinet body 1 with ventilation openings on both sides of the cabinet body 1, a horizontal ventilation plate 2, a multi-stage heat dissipation mechanism 3 and an automatic Fire extinguishing device 4, the horizontal ventilation plate 2 is installed at the vent, the horizontal ventilation plate 2 has a built-in horizontal exhaust fan, the air outlet direction of the horizontal exhaust fan points to the outside of the cabinet body 1, and the multi-stage heat dissipation The mechanism 3 is arranged inside the cabinet body 1, and the automatic fire extinguishing device 4 is placed outside the cabinet body 1;

[0032] The multi-stage heat dissipation mechanism 3 includes a double-sided mesh partition 31 and a micro fan 32, the double-sided mesh partition 31 is equidistantly fixed inside the cabinet body 1, and the micro fan 32 is placed on the double...

Embodiment 2

[0038] The preferred embodiment of the present invention has made the following optimizations on the basis of Embodiment 1: the double-sided mesh partition 31 and the horizontal ventilation panel 2 are rectangular, and the double-sided mesh partition 31 and the horizontal ventilation panel 2 are All have 5 micro-fans 32, and described micro-fans 32 are installed by the arrangement mode of each one in four corners, one in the center.

[0039] The working principle of this embodiment: a miniature fan 32 is all built in the prior art double-sided mesh partition 31 and the horizontal ventilation plate 2, because the cross-sectional area of the cabinet is larger, when using a single miniature fan 32 to drive, the wind force will The area of dead angle that can be covered is just larger, and at the same time, when a single micro fan 32 is working, if the motor breaks down, it will not be able to operate normally. Since the cabinet is rarely opened, problems cannot be found in tim...

Embodiment 3

[0041] The preferred embodiment of the present invention has made the following optimizations on the basis of Embodiment 1: the described air dust removal device 5 is also included, and the air dust removal device 5 is placed at the bottom of the cabinet body 1, and the air dust removal device 5 includes a corona electrode 51. Dust collecting pole 52, transformer 53, protective shell 54 and dust container 55, the corona pole 51 is connected to the transformer 53, the transformer 53 is connected to the protective shell 54, and the corona pole 51 is placed in the dust collecting In the gap between the poles 52, the protective shell 54, the dust container 55 and the transformer 53 are placed at the bottom of the cabinet body 1, the dust container 55 is placed at the bottom of the protective shell 54, the corona pole 51 and the dust collector The pole 52 is placed inside a protective case 54 .

[0042] The working principle of this embodiment: in the prior art, the heat dissipatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com