Fabrication method of Ag/ZnO core-shell structure nanorod array electrode material

A nanorod array and core-shell structure technology, applied in the field of solar cells, can solve the problems of low charge collection efficiency of solar cells, and achieve the effects of low production cost, simple operation, and easy process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

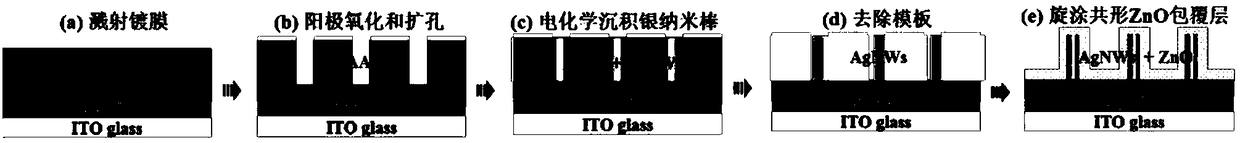

[0017] The implementation of the method of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] A method for preparing an Ag / ZnO core-shell structure nanorod array electrode material, the specific steps comprising:

[0019] Step 1. Clean the ITO glass substrate (14mm x 14mm) ultrasonically with detergent, acetone, isopropanol, and ethanol for 10 minutes in sequence, and finally dry it with dry nitrogen for use.

[0020] Step two, such as figure 1 As shown in a, put the ITO glass substrate into the vacuum sputtering machine (vacuum degree ~ 10 -7 mbarr), followed by sputtering the bonding layer Ti (5nm), nucleation layer Au (2nm) and Al film (150nm).

[0021] Step three, such as figure 1 As shown in b, the above sample is anodized in 0.1M oxalic acid aqueous solution at 5°C (the cathode is a ring-shaped Pt electrode), and the applied voltage is 60V for about 5min to form porous Al 2 o 3 , and then put into 5wt% pho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com