A measuring method of pwm wave duty cycle under the condition of industrial noise

A technology of industrial noise and measurement methods, applied in measurement devices, measurement of electrical variables, measurement of current/voltage, etc., can solve the problem of low sensitivity of analog measurement methods, high requirements for test equipment, and limitation of the maximum testable frequency of the signal to be measured. and other problems to achieve the effect of reducing errors and eliminating interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

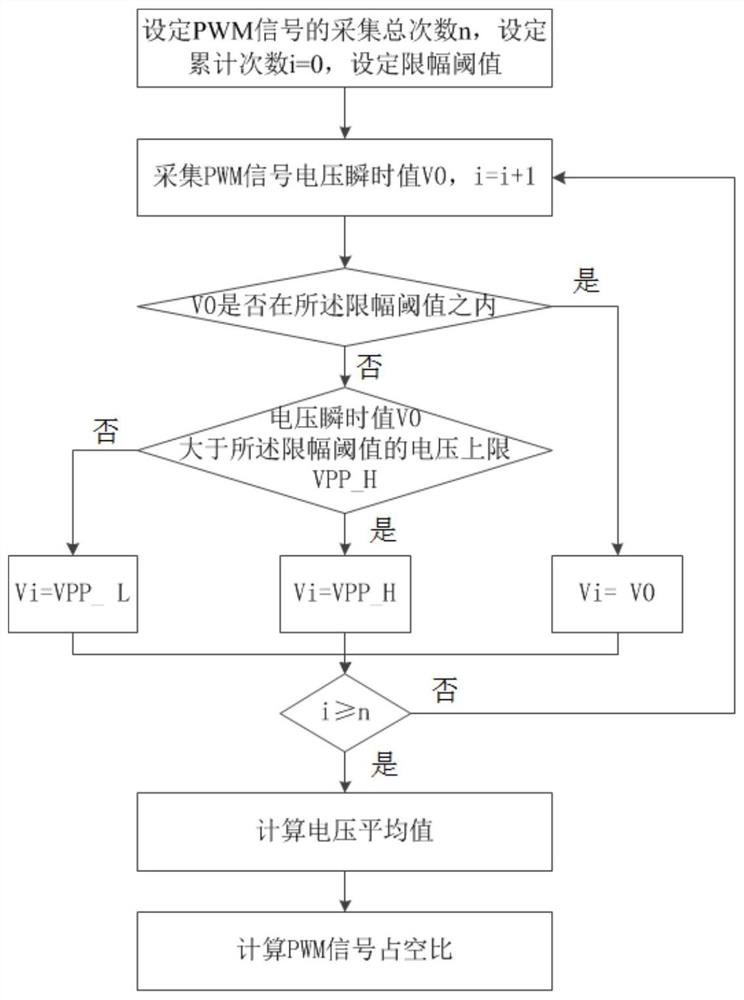

[0037] A method for measuring the duty cycle of PWM waves under industrial noise conditions: collect the instantaneous value of the voltage of the measured PWM signal, limit the collected instantaneous value of the voltage according to the set clipping threshold, and limit the value according to several voltages collected multiple times The mean value of the instantaneous value and the upper limit of the clipping threshold obtain the duty cycle of the periodic signal to be measured. Specifically include:

[0038] Step 1, setting the total number of acquisition times n of the PWM signal, setting the cumulative number of times i=0, and setting the clipping threshold;

[0039] Step 2, collect the instantaneous value of the PWM signal voltage V 0 , i=i+1;

[0040] Step 3, judge the instantaneous value of the voltage V 0 is within the clipping threshold,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com