A steam generator inclined tube bundle heat exchange experimental device and method

A technology of steam generator and experimental device, which is applied in the direction of thermal development of materials, etc., can solve problems such as inability to conduct inclined tube bundle experiments, and achieve the effects of easy processing, low cost, and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

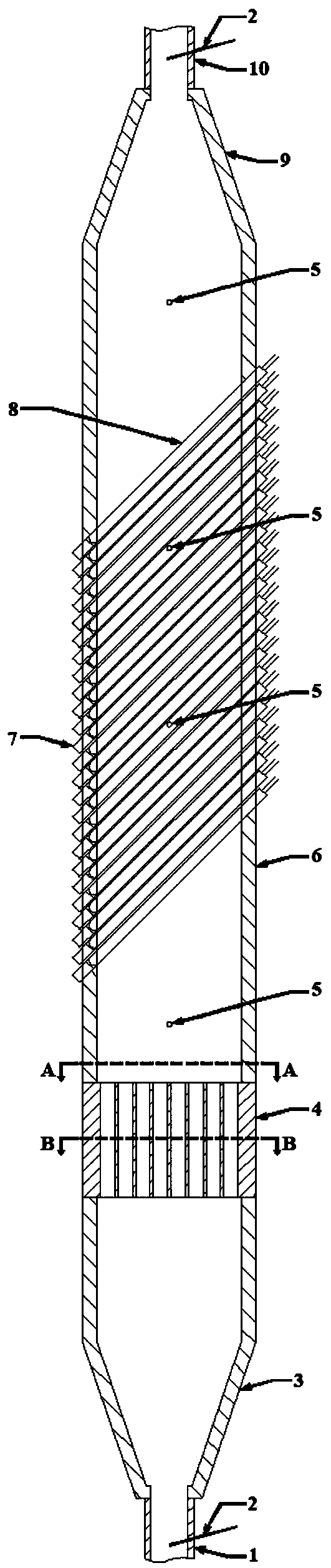

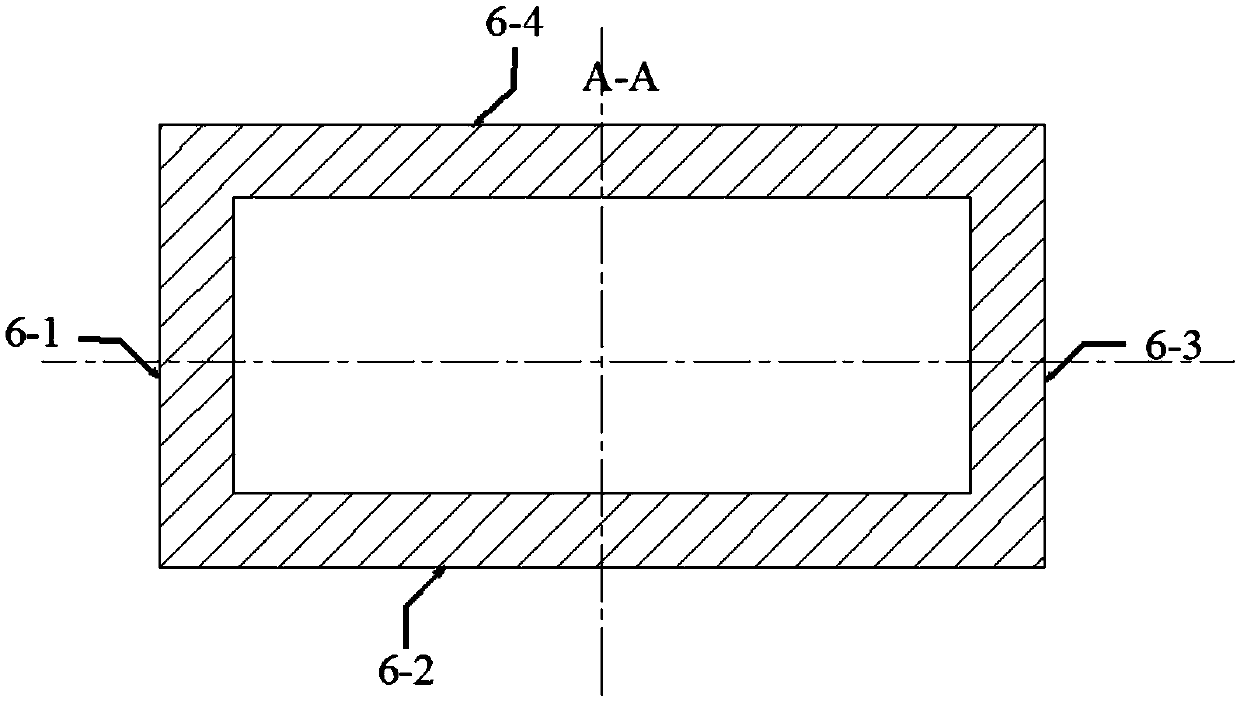

[0027] Such as figure 1As shown, a steam generator inclined tube bundle heat exchange experiment device includes a rectangular casing 6, which is sequentially welded to the inlet diverging section 3 and the inlet connecting pipe 1 at the lower part of the rectangular casing 6, and sequentially welded to the outlet at the upper part of the rectangular casing 6. The tapered section 9 and the outlet connecting pipe 10, the experimental device is connected with the test piping system through the inlet connecting pipe 1 and the outlet connecting pipe 10, and the inlet connecting pipe 1 and the outlet connecting pipe 10 are respectively welded with thermocouples 2; the rectangular casing 6 is composed of Four rectangular steel plates are formed by welding the first rectangular steel plate 6-1, the second rectangular steel plate 6-2, the third rectangular steel plate 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com