A metal non-destructive flaw detection device with electronic display function

A non-destructive detection and electronic display technology, which is applied in the direction of optical testing for flaws/defects, can solve the problems of missed detection, inaccurate detection results, large errors, inaccurate detection results, etc., and achieve the effect of improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

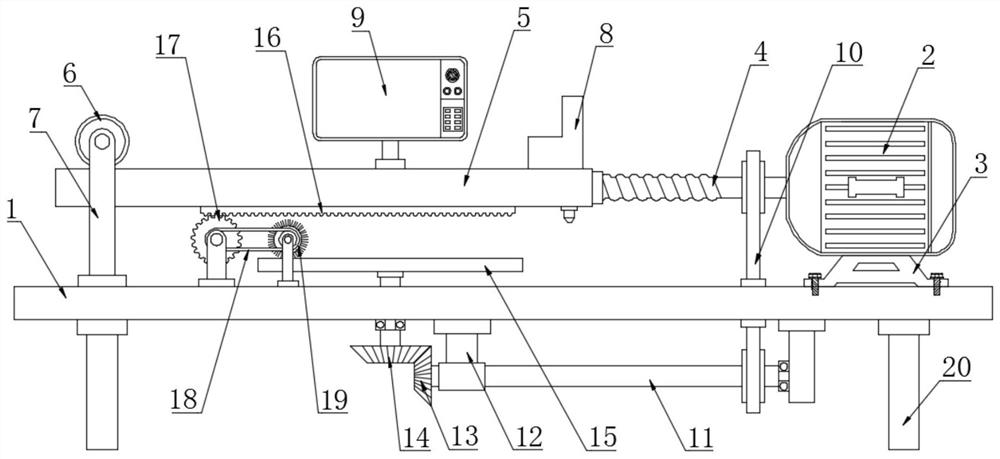

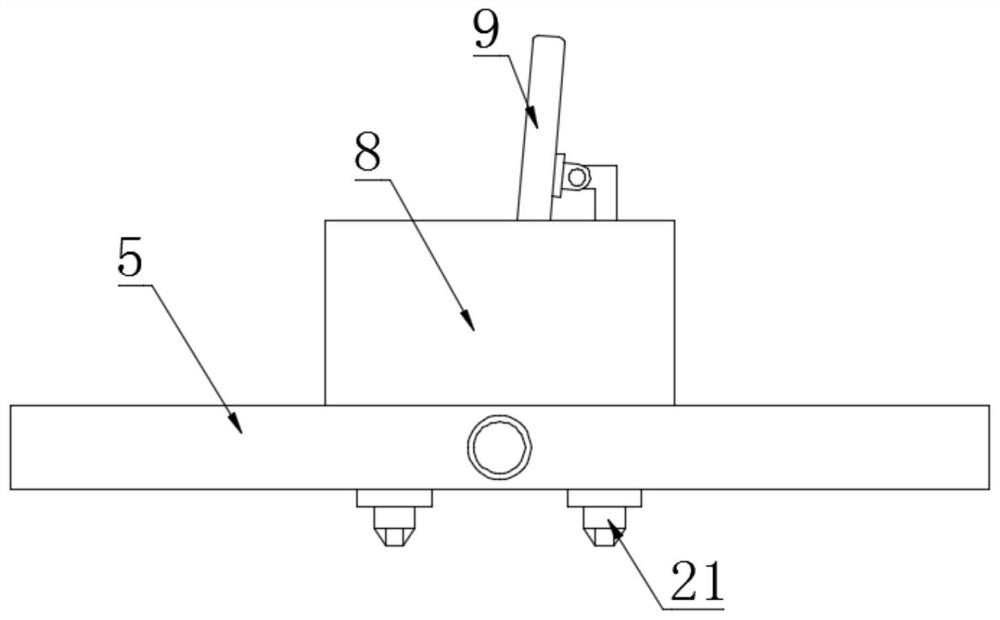

[0020] see Figure 1~3 , in an embodiment of the present invention, a metal non-destructive flaw detection device with electronic display function, comprising a base plate 1, a movable top plate 5 and an infrared detector 8; a servo motor 2 is arranged above the end of the base plate 1, and the servo motor 2 is connected by wires Power supply and switch, the lower part of the servo motor 2 is fixedly connected to the motor base 3, the motor base 3 is fixedly connected to the bottom plate 1 by bolts, the servo motor 2 is rotated and connected to the screw rod 4, and pressing the switch forward makes the servo motor 2 turn on the power to drive the screw rod 4 Rotate in the forward direction, press the switch in the reverse direction to drive the screw rod 4 to reverse; one side of the screw rod 4 is provided with a movable top plate 5, and the middle part of the movable top plate 5 is tapped with a threaded hole, and the screw rod 4 is threadedly connected to the threaded hole i...

Embodiment 2

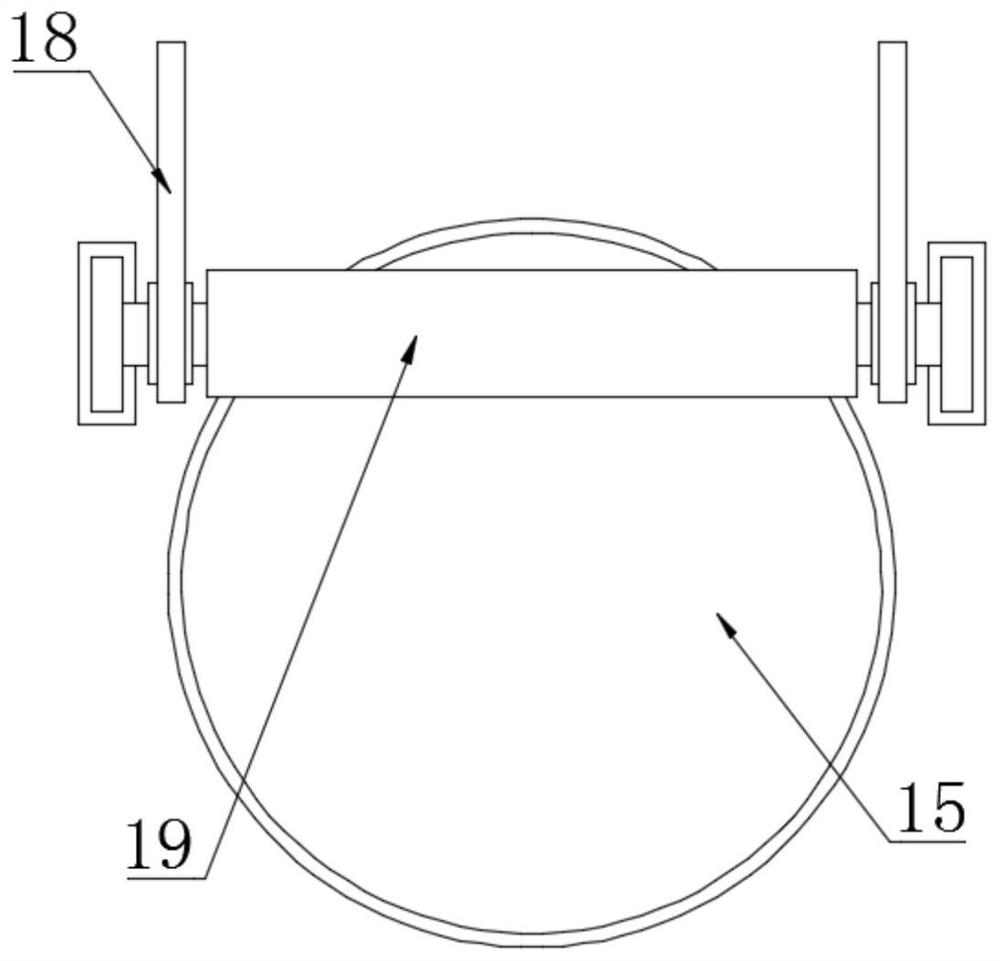

[0023] In order to make the technical solution in this application more abundant and detailed, further supplementary explanations will be made on the basis of the above-mentioned embodiment 1. By adding some technical features, the technical solution of this application will be more complete and substantial, and the disclosure will be more sufficient. , the added part of the technical feature is that the lower surface of the movable top plate 5 is fixedly connected to the rack plate 16, the gear 17 is engaged under the rack plate 16, the gear 17 is connected to the upper part of the bottom plate 1 in rotation, and a brush roller 19 is arranged on one side of the gear 17, The brush roller 19 is rotatably connected to the top of the bottom plate 1, and the brush roller 19 and the gear 17 are connected by a chain 18, wherein the brush roller 19 is located above the worktable 15, and the movable top plate 5 moving left and right drives the rack plate 16 to follow and then drives the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com