Bracket and bracket assembly

An assembly and support technology, applied in the direction of pipe supports, pipe components, vehicle parts, etc., can solve the problems of limited manufacturing methods, expensive and heavy support components, and achieve the effects of firm retention, simple design, and simplified manufacturing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

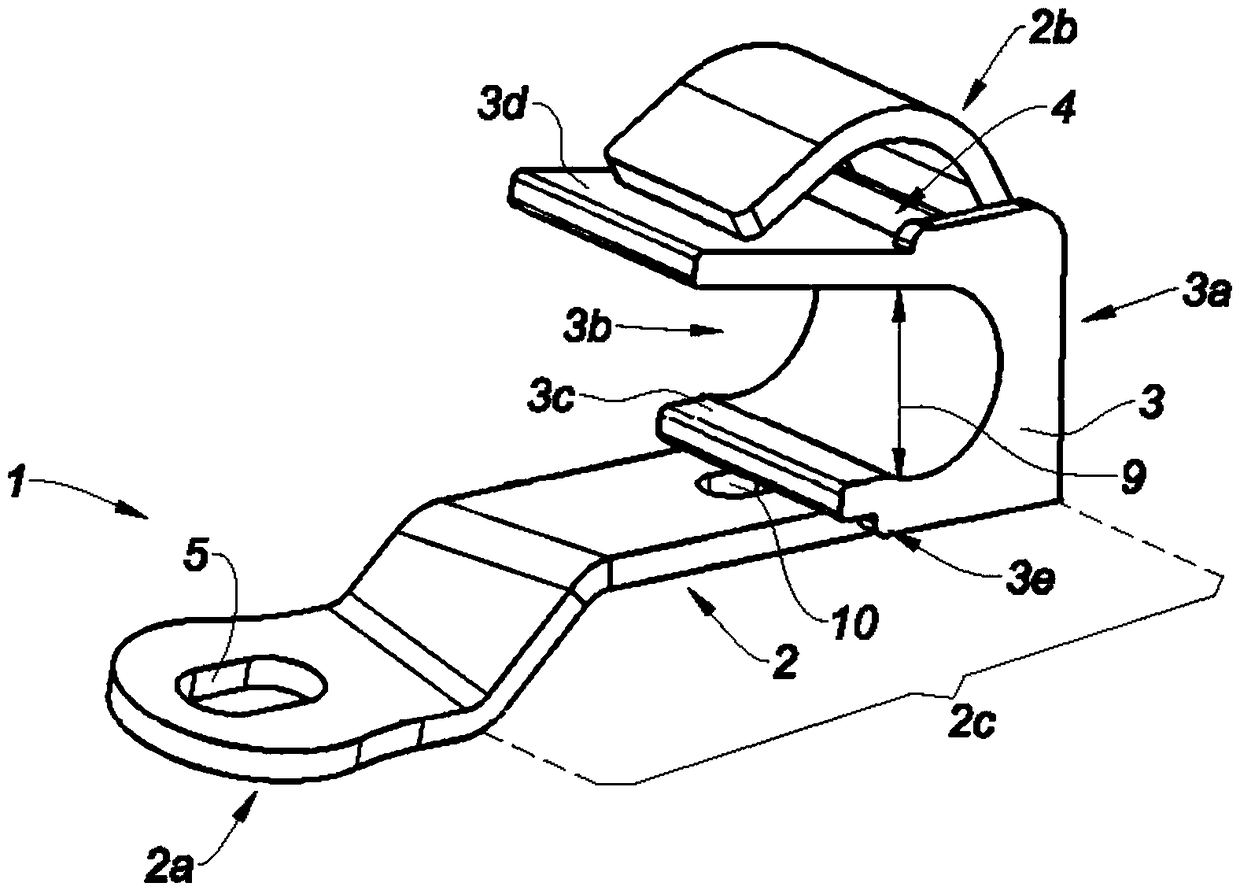

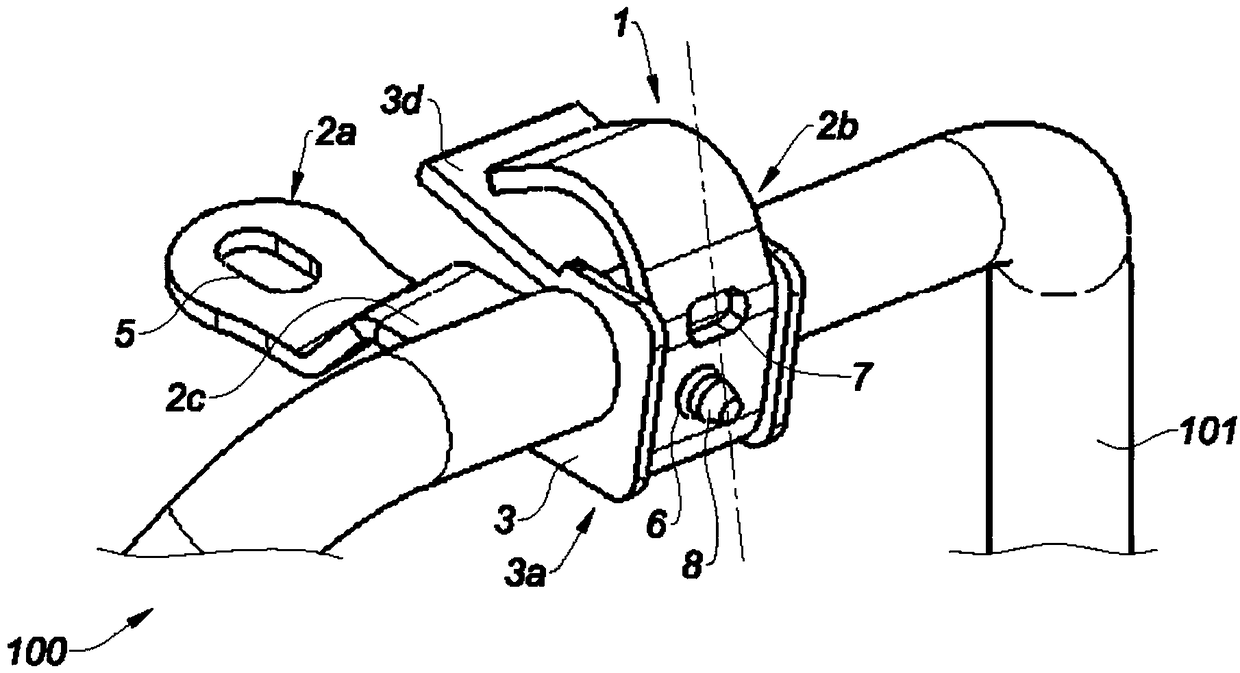

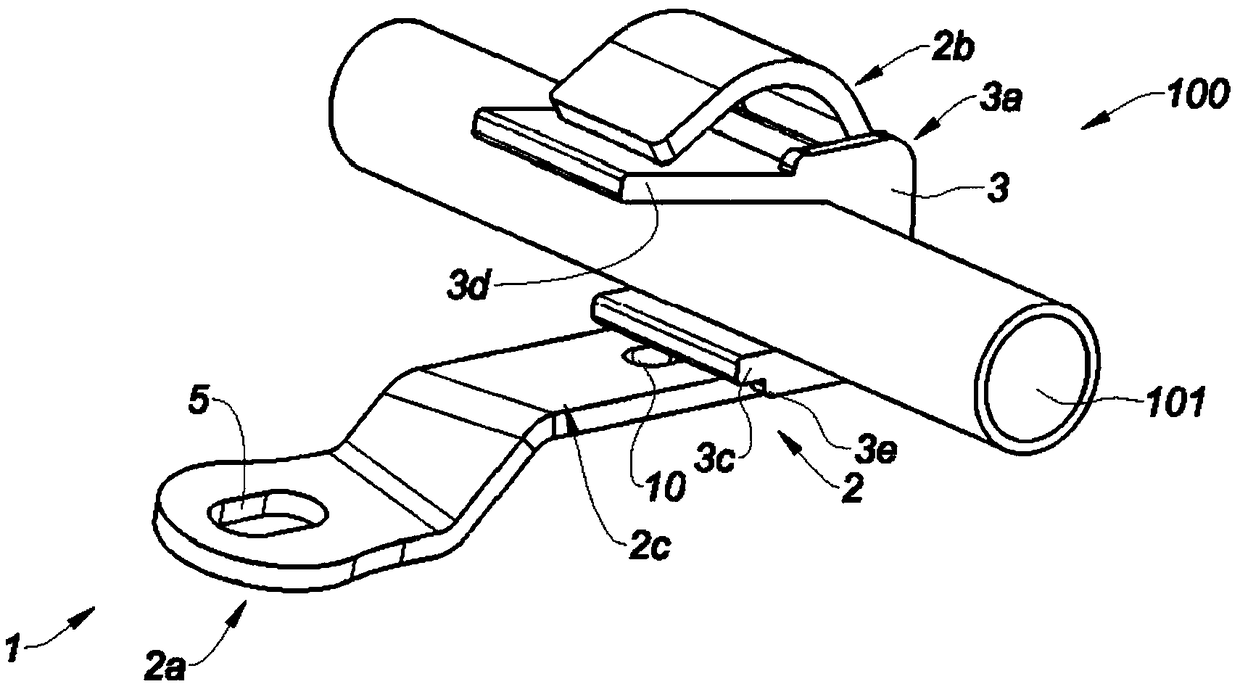

[0077] The stent 1 of the present invention is configured by means of a forming tool 200 to be closed around a pipe element 101 to form a stent assembly 100 . The stent 1 comprises at least one body 2, preferably as figure 1 The metal body shown in 2. The body 2 comprises a first end 2a configured to be fastened to a support, not shown, such as the chassis and engine of a vehicle, preferably a motor vehicle. like figure 1 As shown, the first end 2a includes a fastening interface, such as a fastening hole 5 . The body 2 also includes a second end 2b opposite the first end 2a. The second end 2b is bent to form a bent recess 4 towards the first end 2a and facing the middle portion 2c of the body 2 arranged between the first end 2a and the second end 2b. like figure 2 As shown, the second end 2b includes a positioning opening 7 configured to define the final closed flexed position of the stent 1 .

[0078] like Figures 1 to 3 As shown, the bracket 1 comprises a resilient ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com