Variable-capacity compression mechanism, compressor and air conditioner

A technology of compression mechanism and compression chamber, applied in the field of compressors, can solve the problems of inconvenient control, easy failure, complex structure of variable-capacity compressors, etc., and achieve the effect of simple structure and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

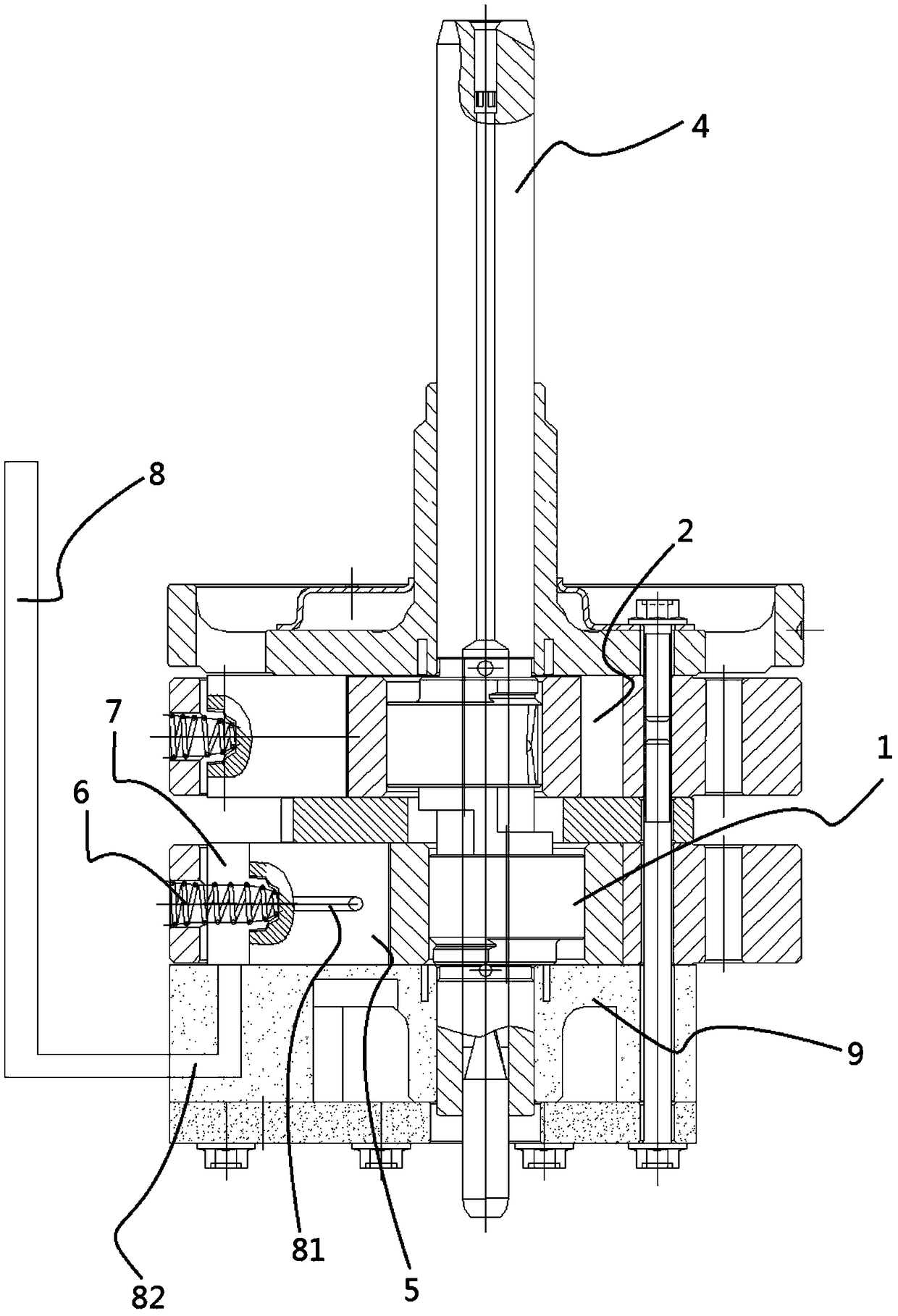

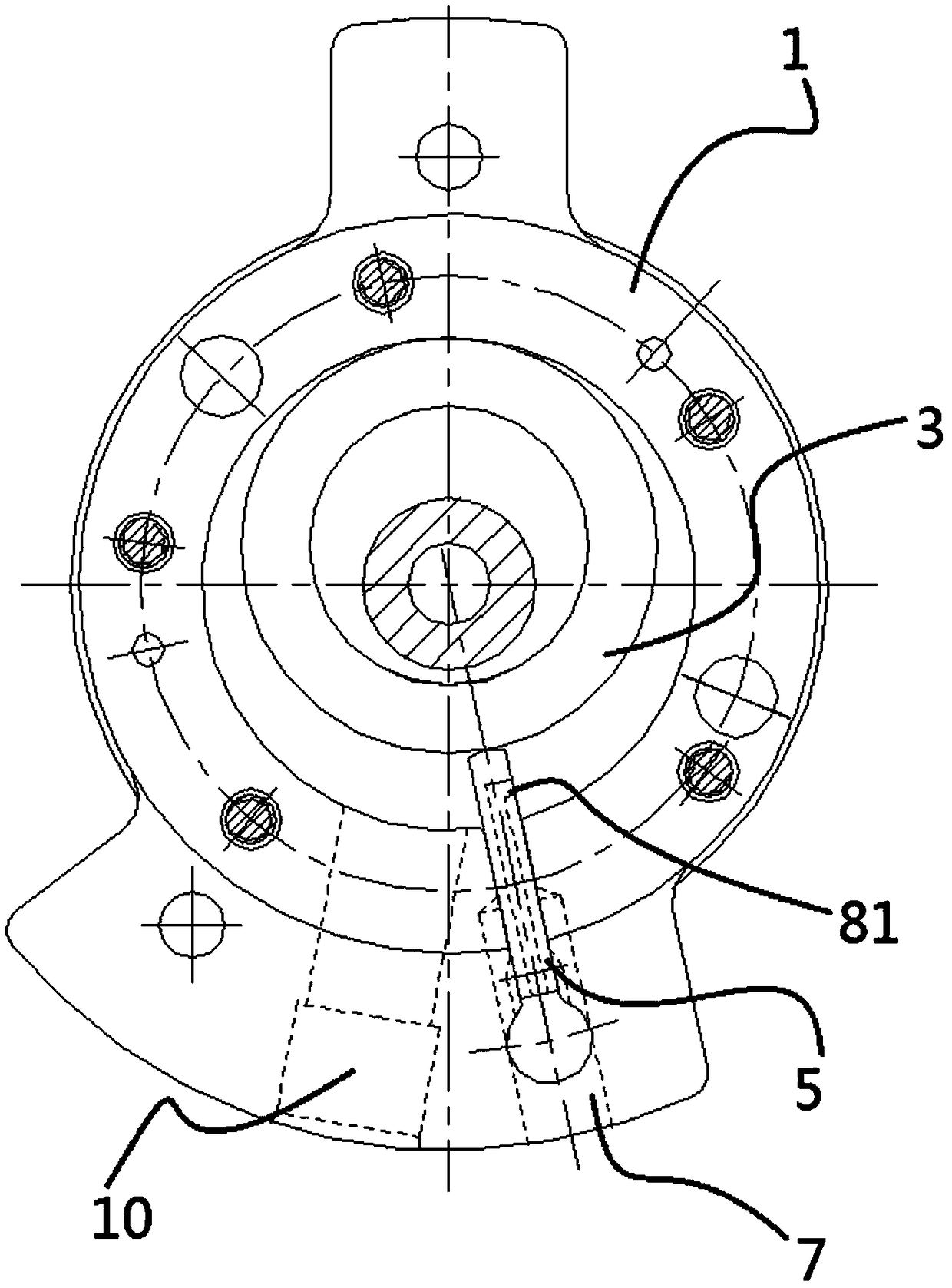

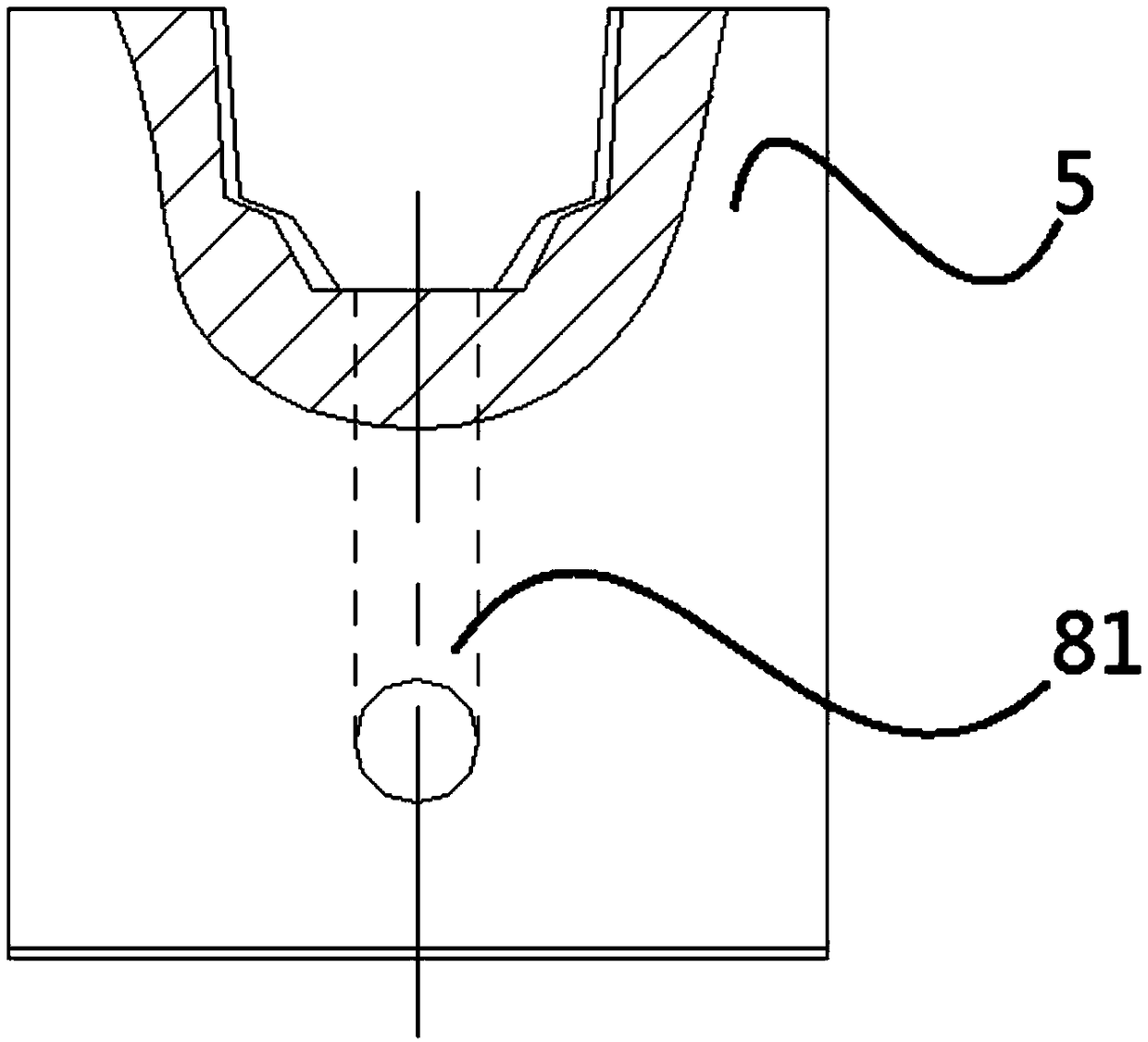

[0034] Such as Figure 1-4 As shown, the variable displacement compression mechanism provided in this embodiment includes a first cylinder 1 having a compression chamber, an air suction port communicated with the compression chamber, and an exhaust mechanism 10 that can be opened at a first preset pressure; The roller 3 is arranged in the compression chamber and moves in a circle along the circumferential inner wall of the compression chamber; a sliding vane 5 assembly is arranged on the circumferential inner wall of the compression chamber, and the sliding vane 5 assembly has A sliding piece 5 capable of reciprocating movement along the radial direction of the accommodating cavity. During the circular motion of the roller 3 in the compression cavity, the inner end of the sliding piece 5 close to the center of the compression cavity is always Against the roller 3, the compression chamber is divided into a suction side connected to the suction port, and a discharge side connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com