A rapid construction method for a double-tower five-span steel box truss cable-stayed bridge

A five-span steel box and construction method technology, which is applied in the construction field of steel box truss girder cable-stayed bridges in bridge engineering, can solve the problems of closing precision and alignment control adverse effects, slow construction speed, etc., and achieves the convenience of box girder alignment control, The effect of high construction precision and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

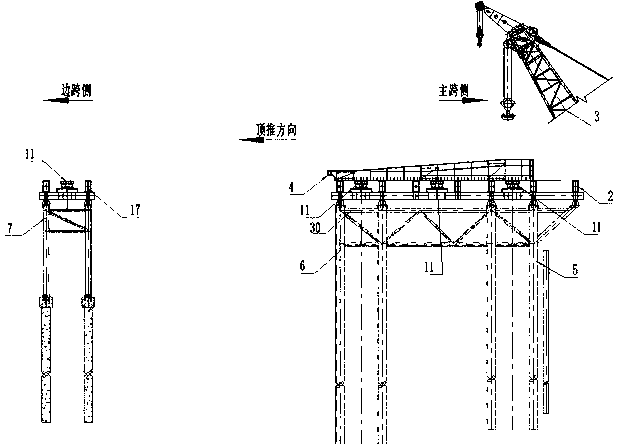

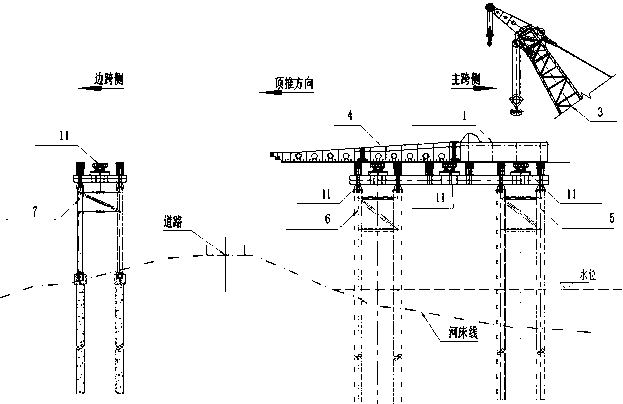

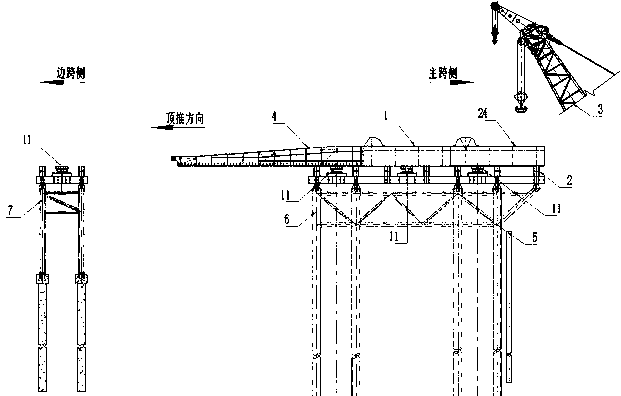

[0042] The present invention will be further described below in conjunction with the accompanying drawings.

[0043] The present invention relates to a rapid construction method for a steel box truss girder cable-stayed bridge with two towers and five spans. Now take the Yuxi River Super Bridge at the fifteenth mark in front of the Shanghe-Hangzhou Railway Station located in Jiujiang District, Wuhu City, Anhui Province as an example. The constructed twin-tower five-span steel box truss cable-stayed bridge consists of two main tower piers and four auxiliary piers, one side of the two main tower piers is arranged symmetrically along the center line between them with two auxiliary piers, including the following step:

[0044] Step 1, such as figure 1 As shown, the first temporary pier 5, the second temporary pier 6 and the third temporary pier 7 are constructed, and the corresponding pushing platform 30 and jack 17 are arranged on the upper end of the temporary pier, and the pus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com