A kind of transparent flame retardant and antistatic pmma composite material and preparation method thereof

A technology of flame retardant and antistatic composite materials, which is applied in the field of transparent flame retardant and antistatic PMMA composite materials and its preparation, can solve the problems of short flame retardant and antistatic cycle, high cost and poor transparency, and achieve flame retardant and antistatic Obvious effects, safe reagents, and cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

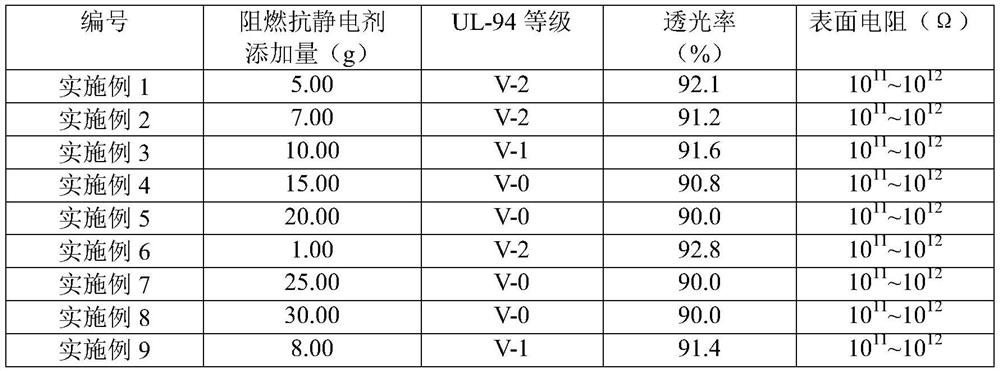

Examples

Embodiment 1

[0036] (1) Put 43.60g of ethylenediamine tetramethylene phosphonic acid and 0.20g of concentrated sulfuric acid in a 250mL three-necked flask equipped with a water separator and a thermometer. Add 6.51g (0.05mol) of hydroxypropyl acrylate dropwise into a three-necked flask through a funnel, make excess ethylenediamine tetramethylene phosphonic acid, and react at 80°C for 6 hours to obtain a crude product, which is purified by vacuum distillation to obtain Flame retardant antistatic agent;

[0037] (2) Mix 94.95g of methyl methacrylate (MMA) and 0.05g (0.05 parts) of azobisisoheptanonitrile (ABVN) and 5.00g of flame retardant antistatic agent in a 250mL flask; place the flask in Prepolymerize in an oil bath at 80°C. After 10 seconds after a large number of bubbles emerge in the flask, the prepolymerization ends. Take out the flask and put it in an ice-water bath until the wall of the flask becomes cold;

[0038](3) Inject the pre-polymerization solution into a steel plate cont...

Embodiment 2

[0040] The difference between Example 2 and Example 1 lies in that the addition amount of the flame retardant antistatic agent in step (2) is 7.00 g, and the rest of the process is exactly the same as that of Example 1.

Embodiment 3

[0042] The difference between embodiment 3 and embodiment 1 is that the addition amount of the flame retardant antistatic agent in step (2) is 10.00 g, and the rest of the process is exactly the same as that of embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap