Cement grinding aid and preparation method thereof

A technology of cement grinding aid and molasses, which is applied in the field of cement grinding aid and its preparation, can solve the problems of low frost resistance and limited application of concrete, and achieve the effect of high freeze-thaw durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

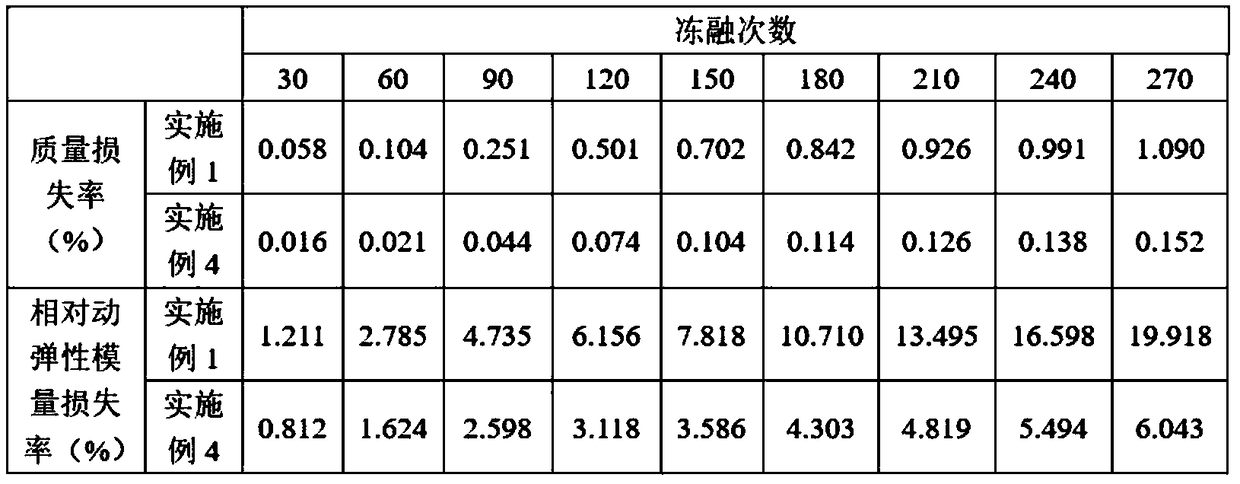

Examples

Embodiment 1

[0016] Embodiment 1: A cement grinding aid, which is prepared by the following method: put metal-organic framework material UIO-66, castor oil, butyl naphthalene sulfonate and sodium lauryl sulfate into water, and disperse evenly ; Add triethanolamine and molasses to the water dispersion, disperse evenly, add apple juice and disperse evenly;

[0017] The mass ratio of water, triethanolamine, molasses, apple juice, metal-organic framework material UIO-66, castor oil, butyl naphthalene sulfonate and sodium lauryl sulfate is 100:22:3:7:9:4 : 1.5: 3; the total sugar content of molasses is 42wt% in terms of converted sugar content.

Embodiment 2

[0018] Embodiment 2: a kind of cement grinding aid, the difference with embodiment 1 is that water, triethanolamine, molasses, apple juice, metal-organic framework material UIO-66, castor oil, butyl naphthalene sulfonate and The mass ratio of sodium lauryl sulfate is 100:20:2:6:8:3:1:2; the total sugar content of molasses is 40wt% in terms of converted sugar content.

Embodiment 3

[0019] Embodiment 3: a kind of cement grinding aid, the difference with embodiment 1 is that water, triethanolamine, molasses, apple juice, metal-organic framework material UIO-66, castor oil, butyl naphthalene sulfonate and The mass ratio of sodium lauryl sulfate is 100:25:4:8:10:5:2:4; the total sugar content of molasses is 45wt% in terms of converted sugar content.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com