An inclined type high-efficiency solid-liquid separation device and its working method

A solid-liquid separation and tilting technology, which is applied in the direction of chemical instruments and methods, special treatment targets, sludge treatment, etc., can solve the problems of increasing the cost of the enterprise, occupying a large area, and slow processing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

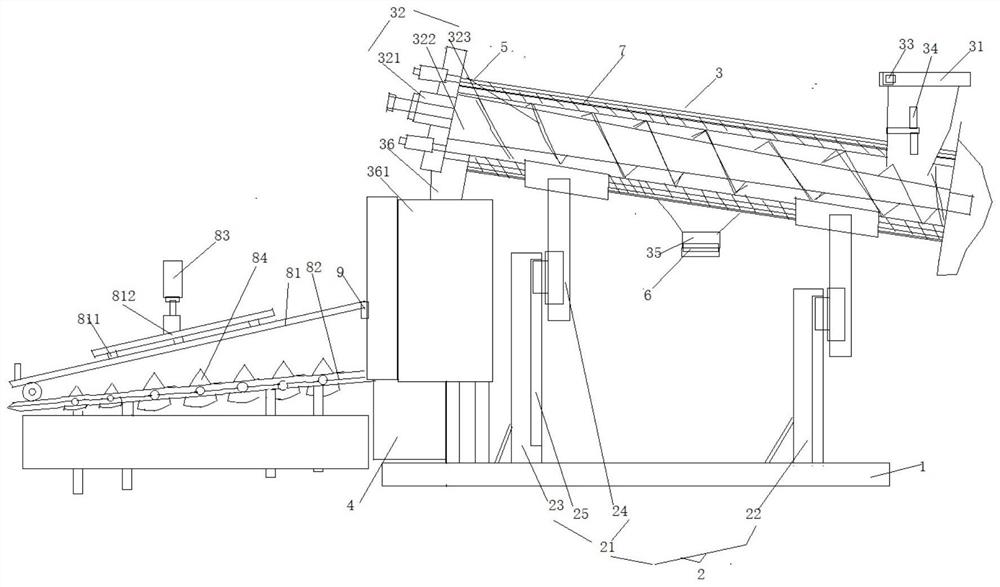

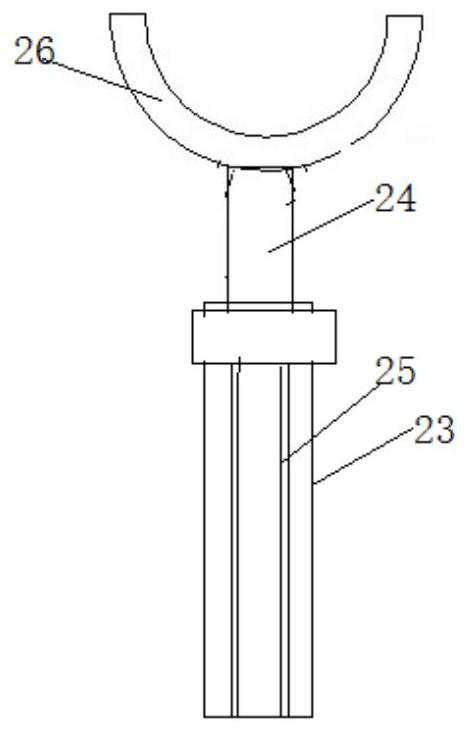

[0035] A tilting high-efficiency solid-liquid separation device as shown in the figure includes: a base 1, a support frame 2, a solid-liquid separation mechanism 3 and a control device 4, wherein the support frame 2 is provided with a first support frame 21 and The second support frame 22, the height of the first support frame 21 is higher than the height of the second support frame 22, and the solid-liquid separation mechanism 3 is arranged on the support frame 2 in an inclined shape;

[0036]The solid-liquid separation mechanism 3 is provided with a feed inlet 31, a separation mechanism 32 and a housing 5, the separation mechanism 32 is located inside the housing 5, and the feed inlet 31 is located on the top of the housing 5 , the feed inlet 31 is provided with a first moisture detection mechanism 33, and the feed inlet 31 is provided with a stirring mechanism 34, and the separation mechanism 32 is provided with a drain outlet 35 below, and the separation mechanism 32 One e...

Embodiment 2

[0047] A tilting high-efficiency solid-liquid separation device as shown in the figure includes: a base 1, a support frame 2, a solid-liquid separation mechanism 3 and a control device 4, wherein the support frame 2 is provided with a first support frame 21 and The second support frame 22, the height of the first support frame 21 is higher than the height of the second support frame 22, and the solid-liquid separation mechanism 3 is arranged on the support frame 2 in an inclined shape;

[0048] The solid-liquid separation mechanism 3 is provided with a feed inlet 31, a separation mechanism 32 and a housing 5, the separation mechanism 32 is located inside the housing 5, and the feed inlet 31 is located on the top of the housing 5 , the feed inlet 31 is provided with a first moisture detection mechanism 33, and the feed inlet 31 is provided with a stirring mechanism 34, and the separation mechanism 32 is provided with a drain outlet 35 below, and the separation mechanism 32 One ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com