Heating aeration pool for sewage purification and method thereof

A sewage purification and aeration tank technology, applied in chemical instruments and methods, water/sewage treatment, water/sewage treatment equipment, etc., can solve the problems of accelerated oxygen transfer, decreased activity of eutrophic microorganisms, uneven aeration, etc. Achieve the effect of high efficiency, simple structure and maintaining efficient condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

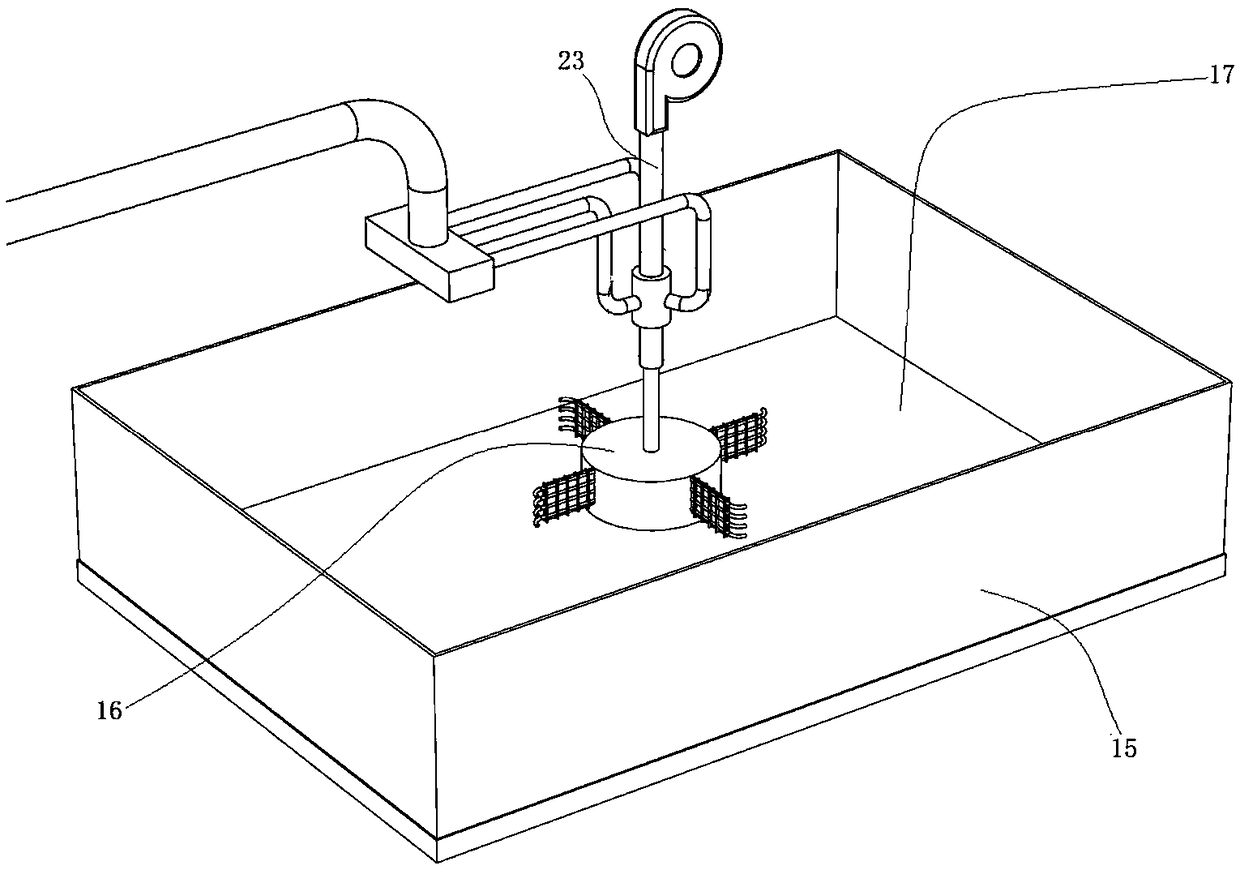

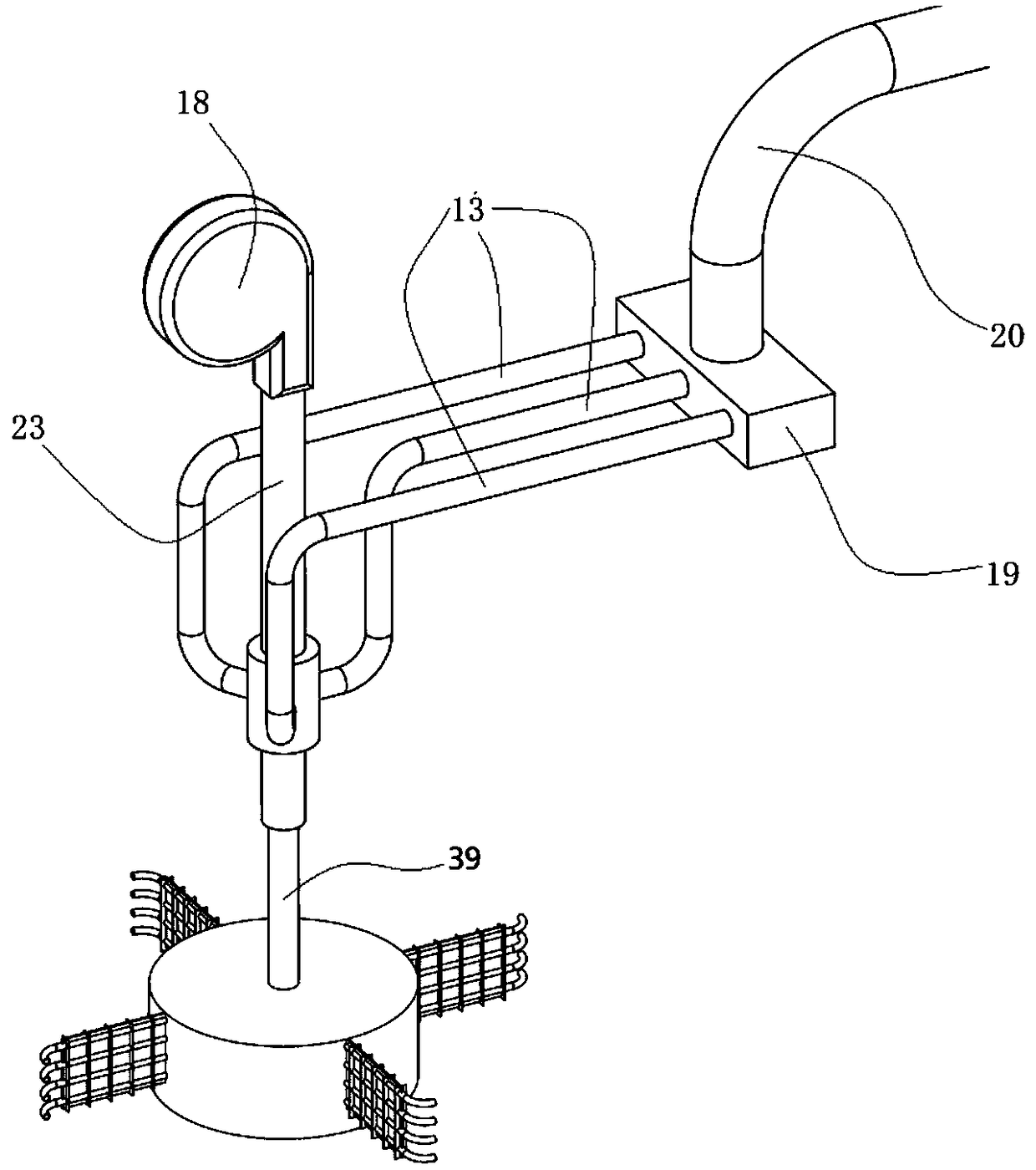

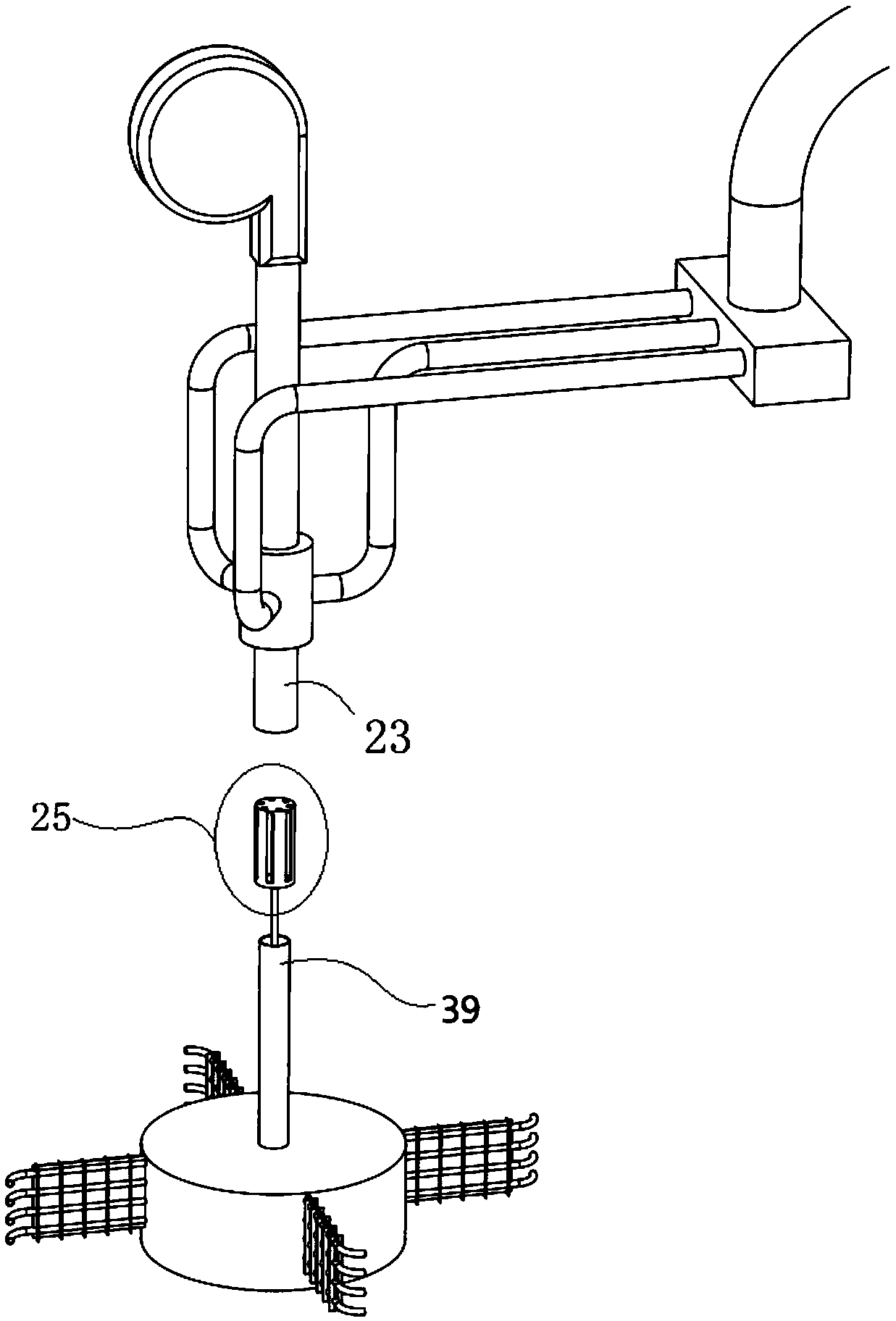

[0031] as attached Figures 1 to 8 A heated aeration tank for sewage purification shown includes an aeration tank 15, and a rotating aeration impeller 16 is arranged in the tank chamber 17 of the aeration tank 15, and the rotating aeration impeller 16 is immersed in The sewage in the pool cavity 17 is below the liquid level.

[0032]The aeration impeller 16 includes a cylindrical gas storage casing 30, and a horizontal spacer 29 is integrated in the inner cavity of the gas storage casing 30, and the upper side of the horizontal spacer 29 is a cylindrical gas storage chamber. 27. The lower side of the horizontal partition plate 29 is a closed floating chamber 28, and the setting of the floating chamber 28 can effectively prevent the aeration impeller 16 from sinking.

[0033] The cylindrical outer wall of the gas storage housing 30 is also integrally connected with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com