Optical fiber wire drawing furnace cooling pipe helium gas recovery device

A helium gas recovery and cooling tube technology, applied in the direction of inert gas compounds, specific gas purification/separation, inorganic chemistry, etc., can solve the problems of low helium recovery rate, unsatisfactory recovery effect, low purity, etc., and achieve recycling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiments of the invention will be described in detail below with reference to the drawings.

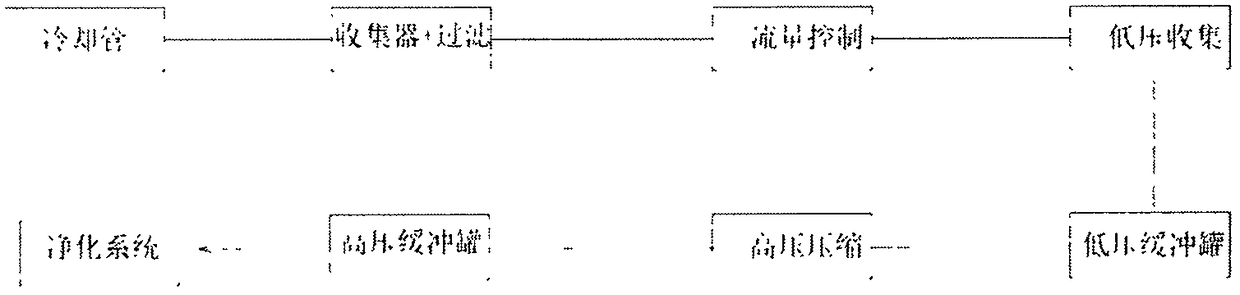

[0017] figure 1 Shows the present invention, a flow chart of the helium recovery system for the cooling pipe of the drawing furnace. After the helium is discharged from the cooling pipe of the drawing furnace, it passes through the helium collector and filter, passes through the mass flow control valve to the low-pressure collection stage, passes through the low-pressure collection, and then flows to the low-pressure buffer tank, and after the low-pressure buffer tank, it reaches the high-pressure In the compression stage, the high-pressure buffer tank after high-pressure compression leads to the purification system.

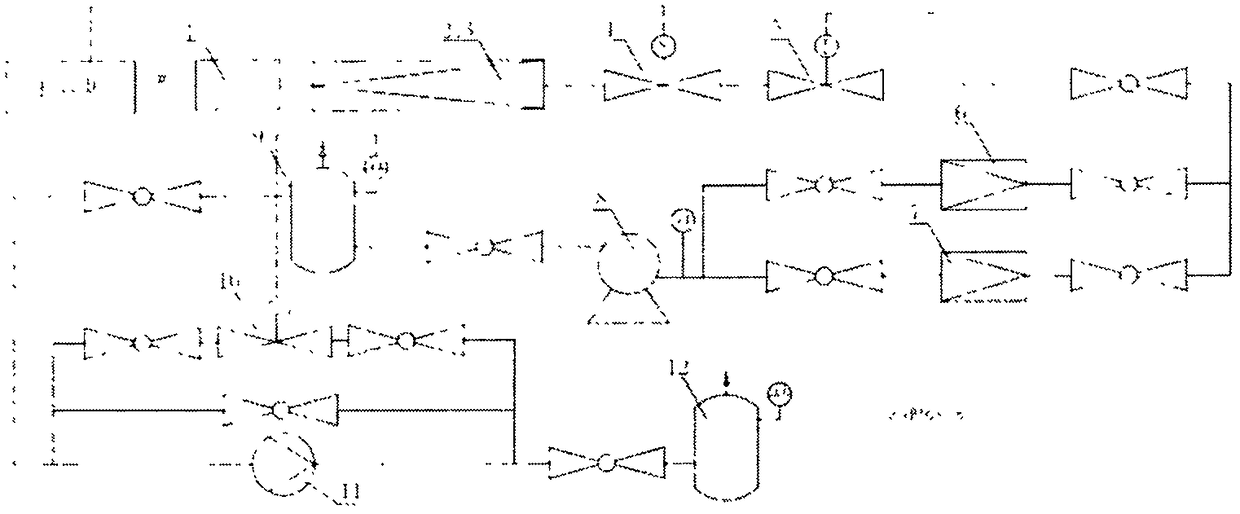

[0018] Such as figure 2 As shown in the present invention, a wire drawing furnace recovery device sequentially includes: 1. helium recovery device; 2, 3, filter; 4. solenoid valve; 5. mass flow regulating valve; 6, 7, filter; 8 helium Vacuum pump; 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com