Flexible film carrying plate transport mechanism

A technology for handling mechanisms and trays, which is applied to conveyors, transportation and packaging, and stacking of objects, etc. It can solve time-consuming and labor-intensive problems and achieve the effects of wide coverage, small horizontal space occupation, and flat bottom height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

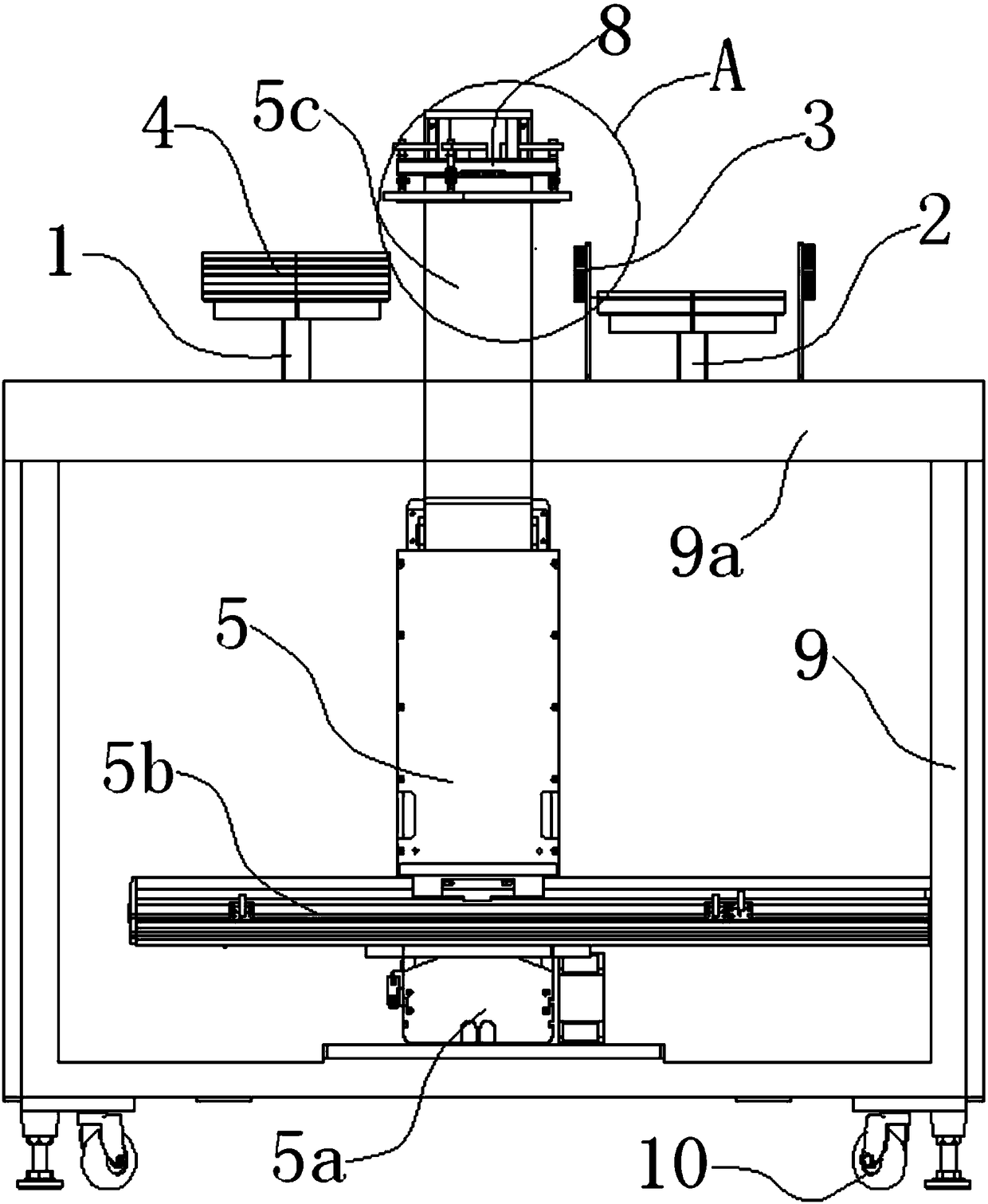

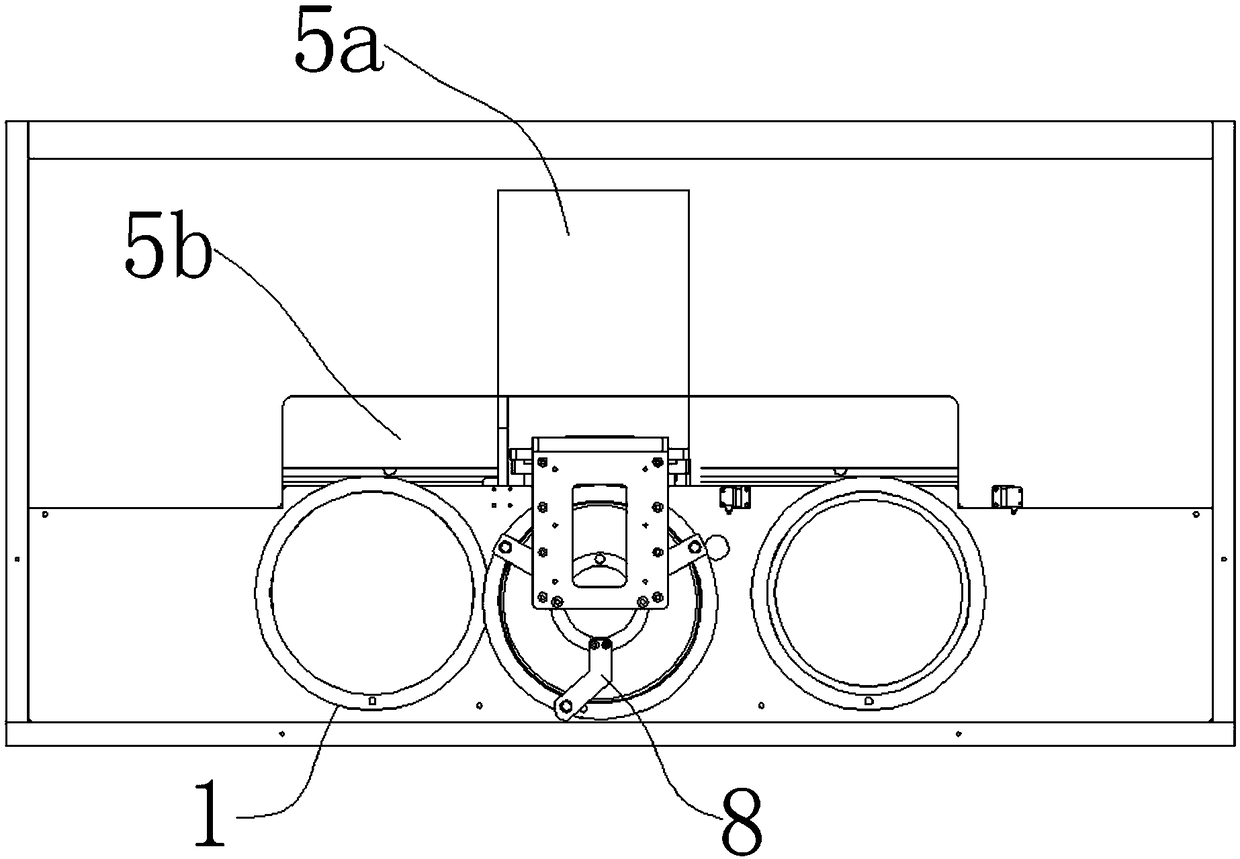

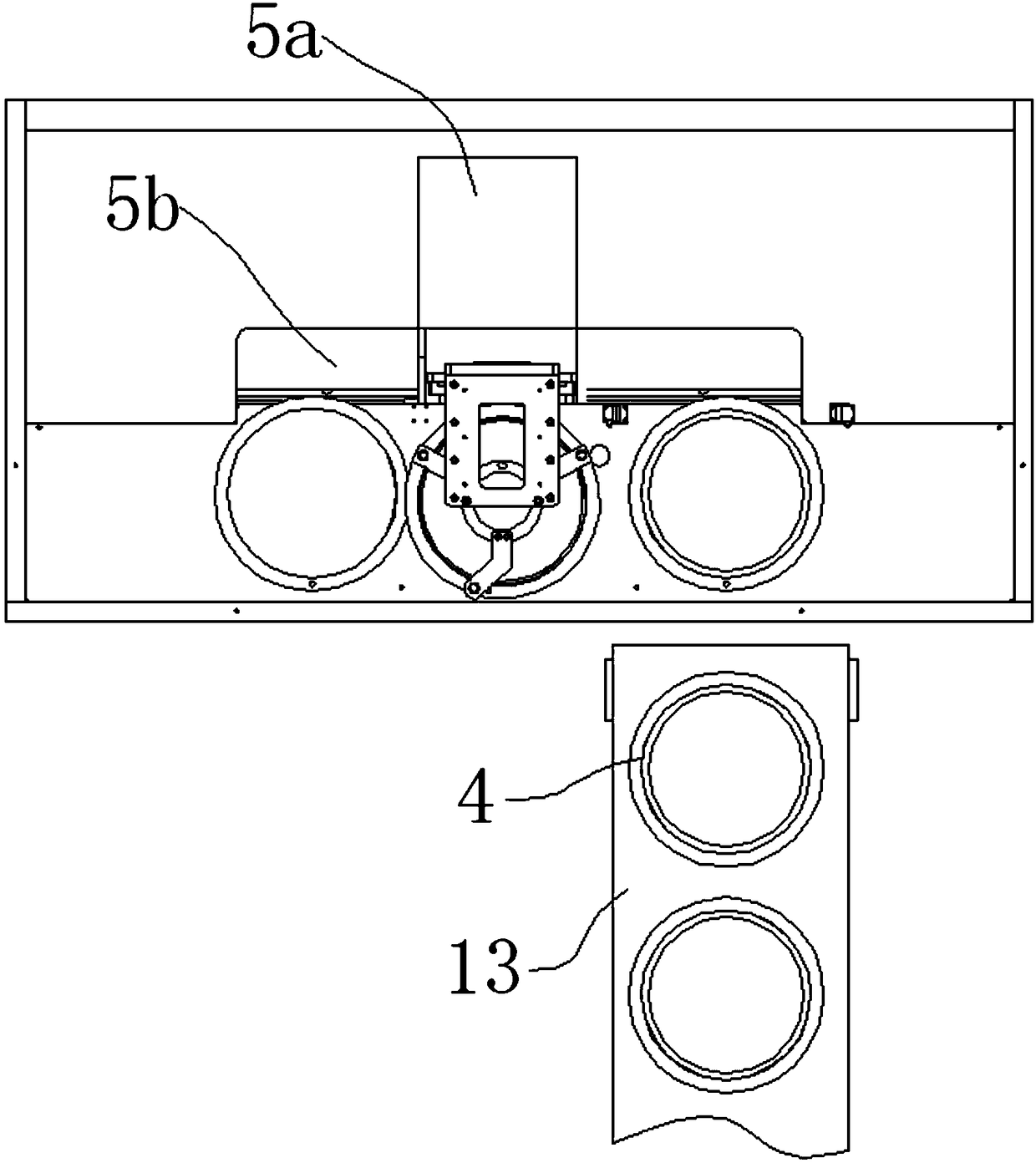

[0033] In order to achieve the purpose of the present invention, a soft film tray handling mechanism includes: vacuum suction pens 6, at least three vacuum suction pens 6 absorb the upper surface edge of the tray 4; manipulator 5, with horizontal and vertical direction The three degrees of freedom of mechanical translation on the top, the vacuum suction pen 6 is located on the manipulator 5; the empty disk storage area 2 is used to stack the empty disks 4 vertically; Sensor 3; soft film carrier tray storage area 1, used for vertically stacked carrier trays 4 equipped with soft film; manipulator 5 places carrier tray 4 between empty tray storage area 2 and soft film carrier tray storage area 1 transfer. The soft film is stored in the depression in the middle part on the top of the carrier disc 4 . The carrier plate 4 that has been transferred with the soft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com