Multifunctional garbage can capable of automatically classifying garbage and working method thereof

A garbage sorting and garbage can technology, applied in the field of garbage cans, can solve the problems of increasing product prices, high prices, and large recognition errors, and achieve the effects of real-time detection capacity, low cost, and high recognition accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

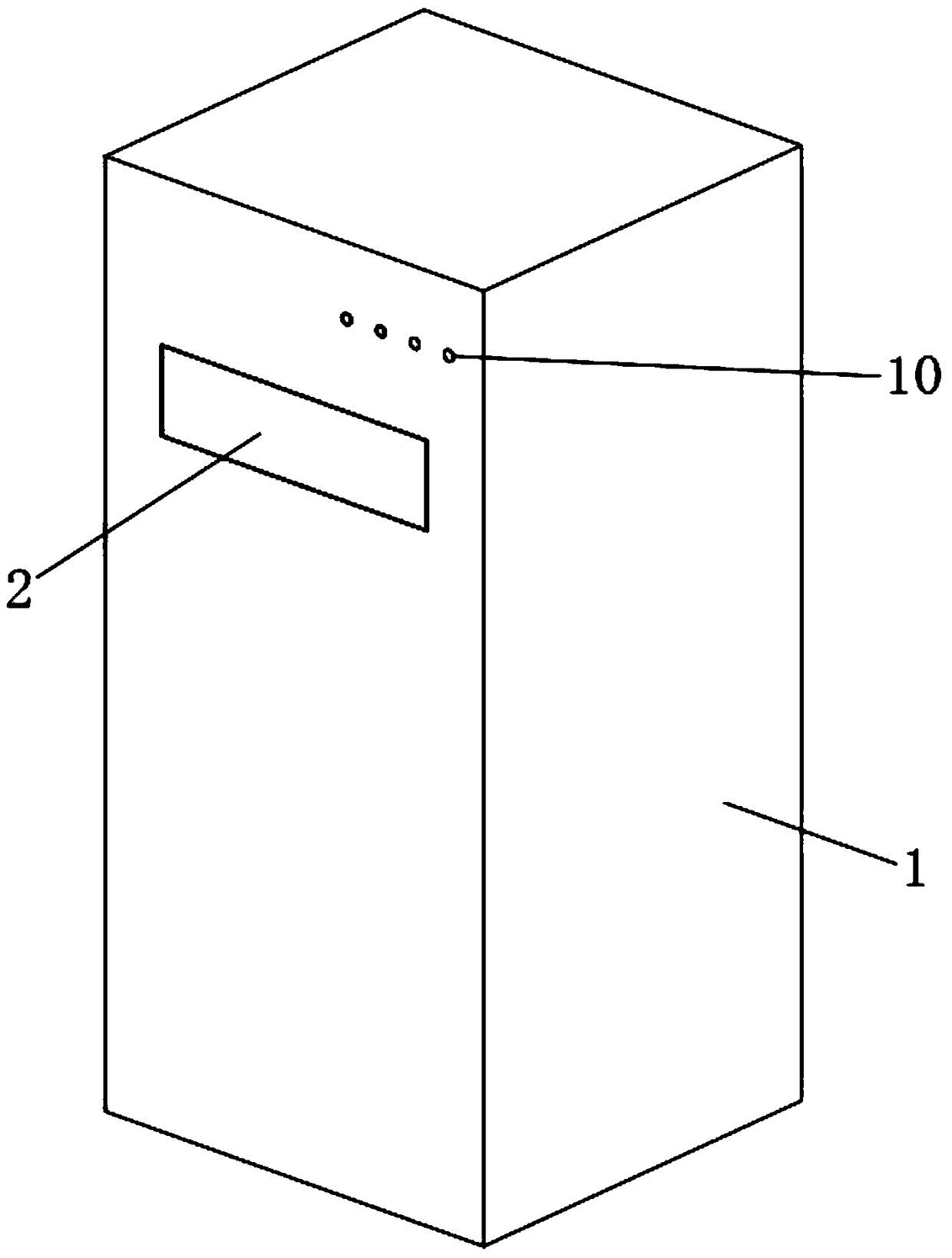

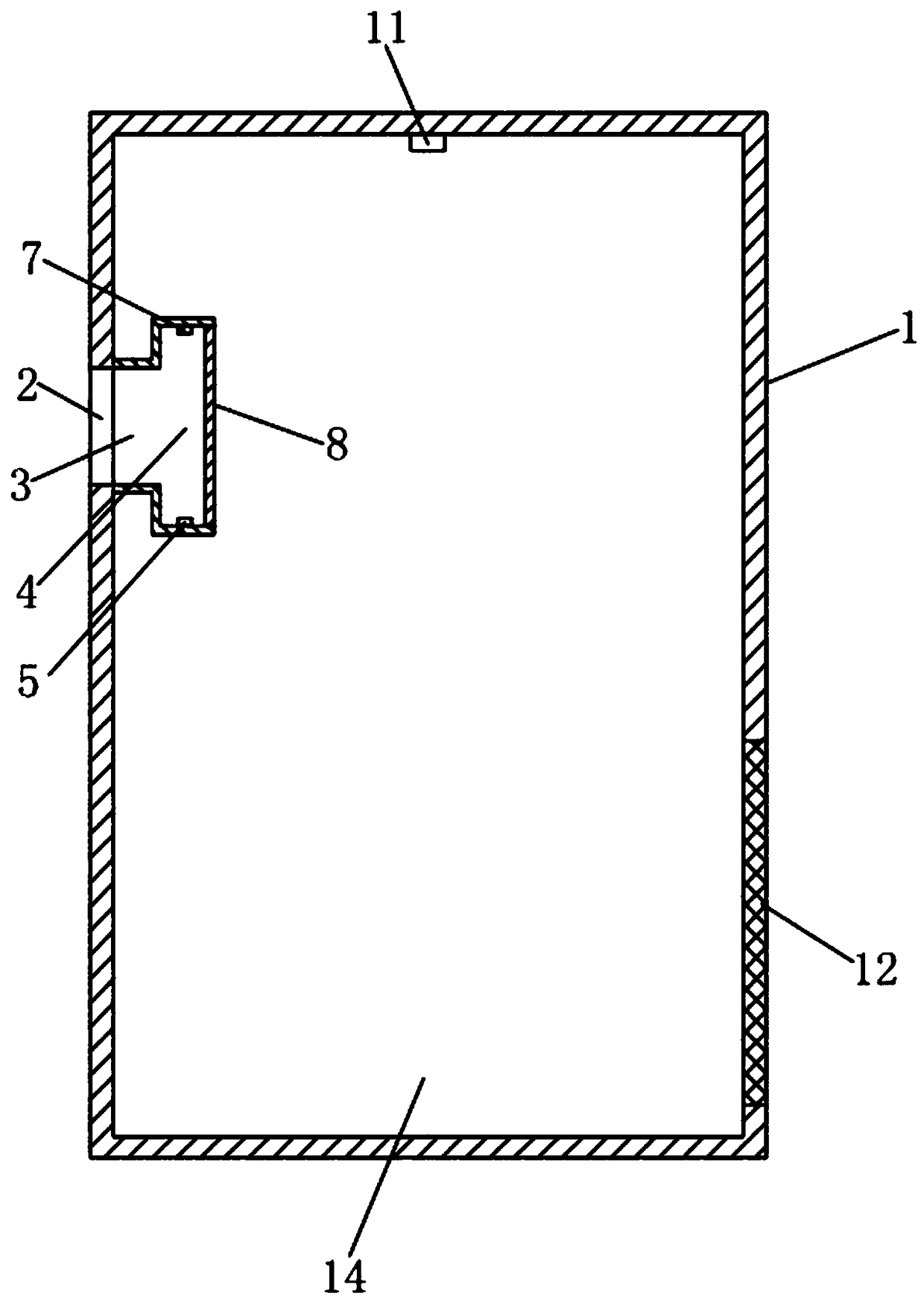

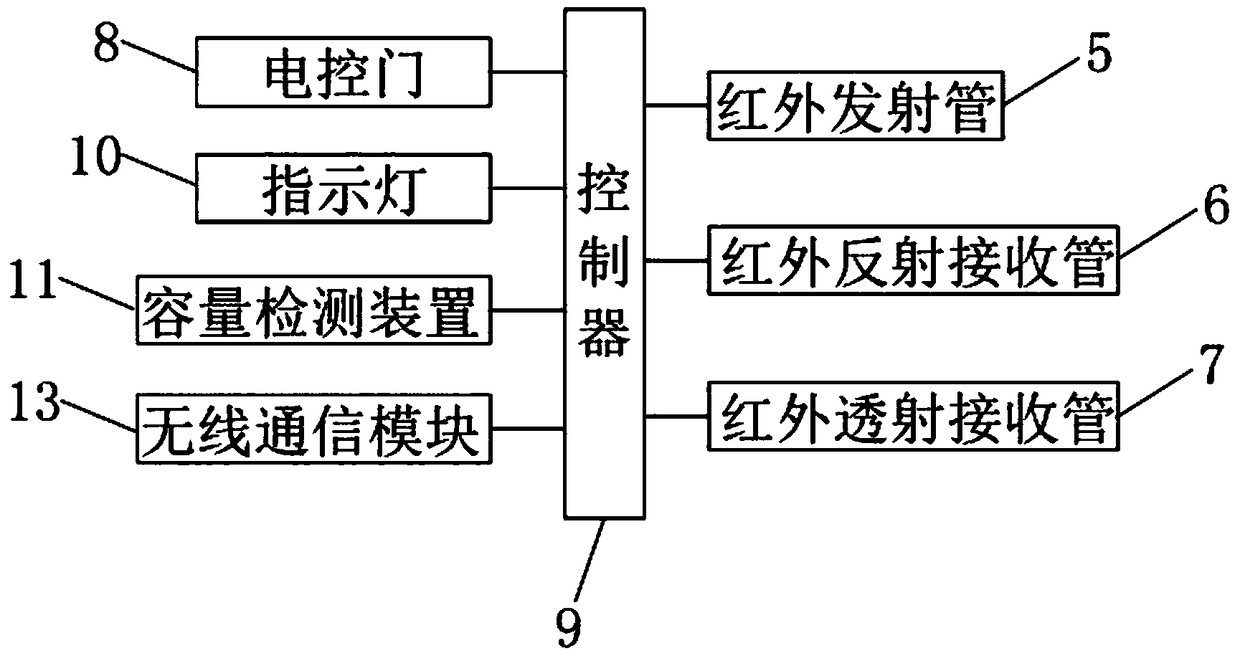

[0035] Embodiment: a kind of multifunctional dustbin of automatic garbage sorting of the present embodiment, as figure 1 , figure 2 , image 3As shown, including barrel body 1, the front side of barrel body 1 is provided with a garbage detection bin, the front side of the garbage detection bin is provided with an entrance 2, and the rear side of the garbage detection bin is provided with an outlet communicating with the inner cavity 14 of barrel body 1, and the garbage detection bin The warehouse includes a first cavity 3 and a second cavity 4, the front side of the first cavity 3 communicates with the inlet 2, the front side of the second cavity 4 communicates with the rear side of the first cavity 3, and the rear side of the second cavity 4 Connected with the outlet, the top level of the second cavity 4 is higher than the top level of the first cavity 3, the bottom level of the second cavity 4 is lower than the bottom level of the first cavity 3, and the second cavity 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com