Anti-fall packing box for glass product

A technology of glass products and packaging boxes, applied in the field of packaging manufacturing, can solve the problems of increasing packaging costs, time-consuming and labor-intensive packaging, etc., and achieve the effect of reducing the incidence of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

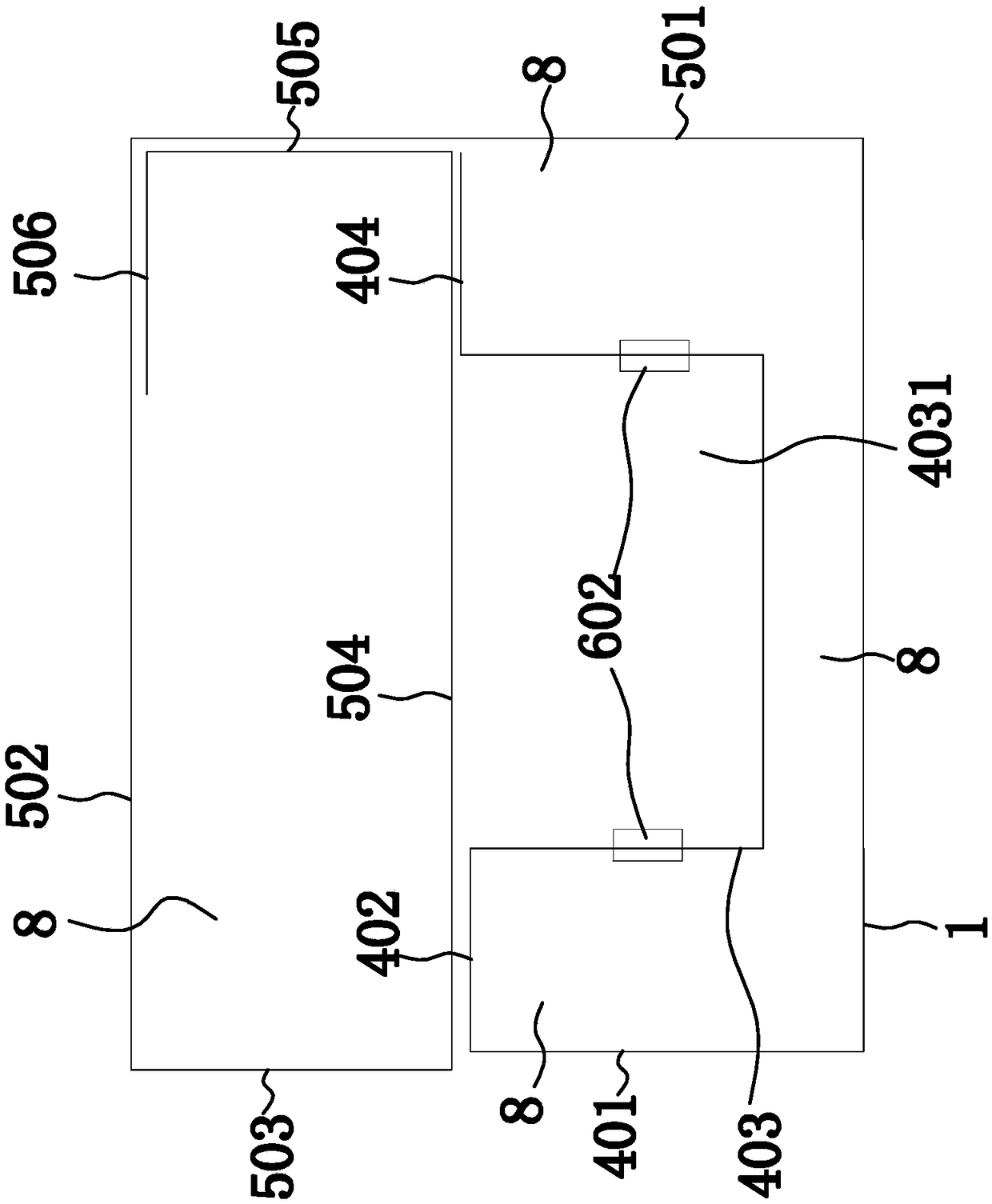

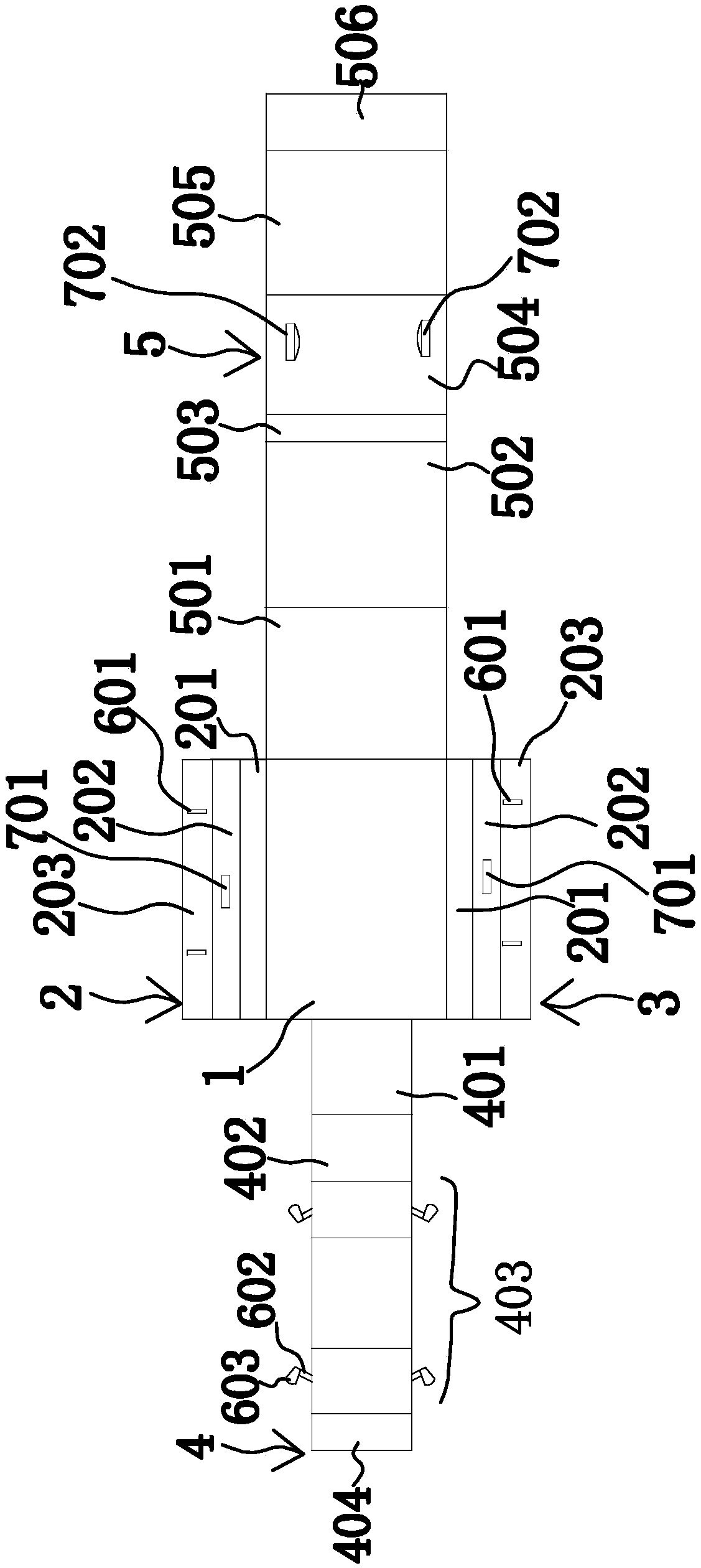

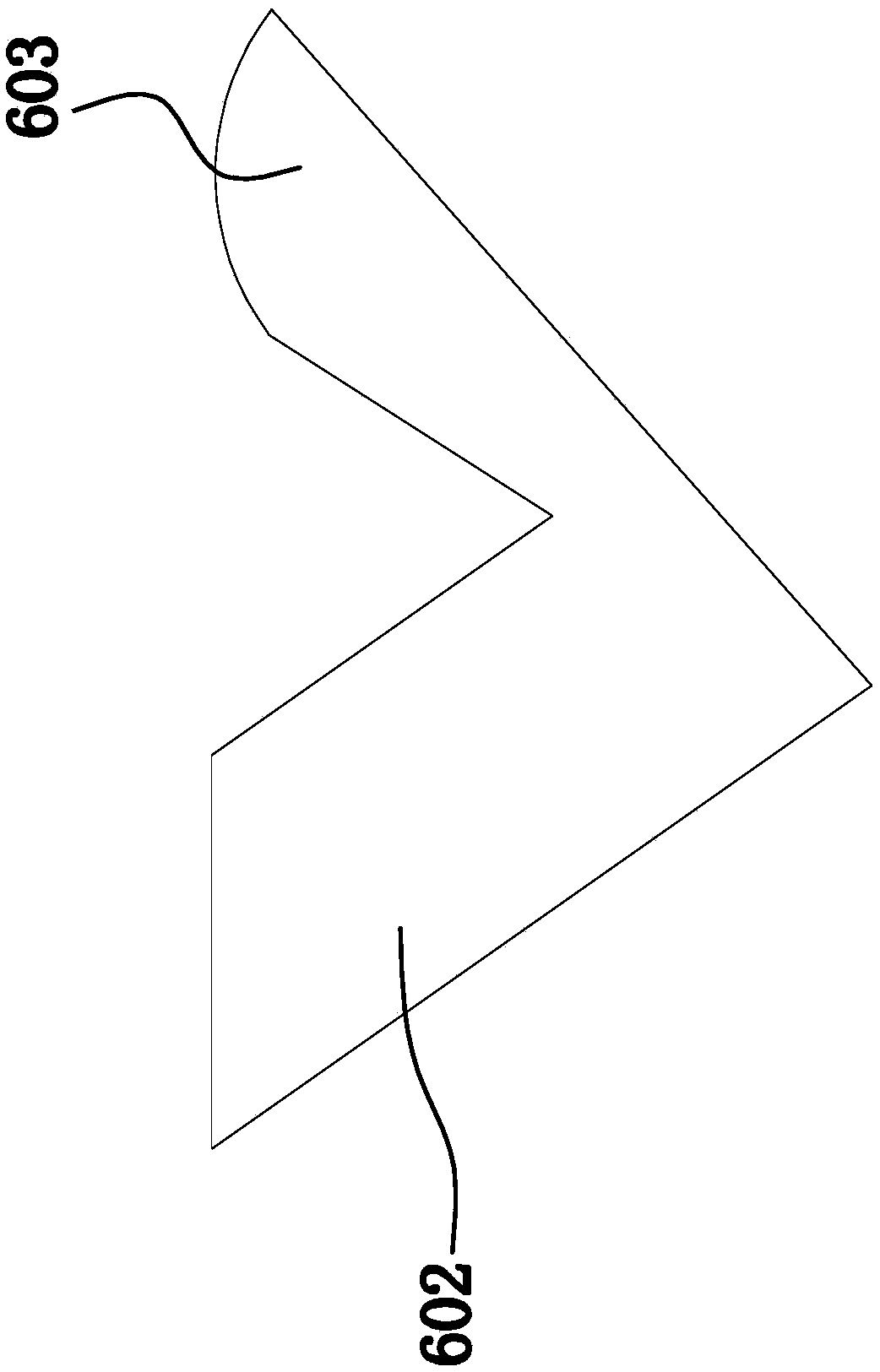

[0020] Such as Figures 1 to 3 As shown, the packaging box for shatter-resistant glass products includes a rectangular cardboard body 1 in the shape of a rectangle. The first side body 2 of cardboard, the second side body 3 of cardboard, and the third side of cardboard are sequentially connected to the side of the rectangular cardboard body 1. The body 4 and the cardboard fourth side body 5, the cardboard first side body 2, the cardboard second side body 3, the cardboard third side body 4 and the cardboard fourth side body 5 are respectively arranged correspondingly, and it is characterized in that: the cardboard first side body The body 2 and the second side body 3 of the cardboard are respectively provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com