Lamp tube packaging box molding machine applied to full-automatic packaging line for LED lamp tube

A fully automatic packaging and LED light tube technology, applied in the types of packaging items, packaging, transportation packaging, etc., can solve the problems of high number of workers, occupying a large production space, and increasing production costs, so as to optimize the packaging process, The effect of reducing the number of workers and improving packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

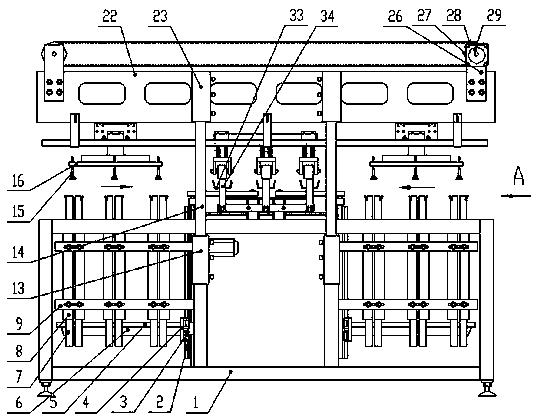

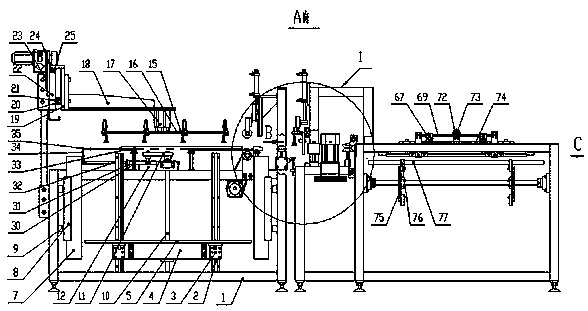

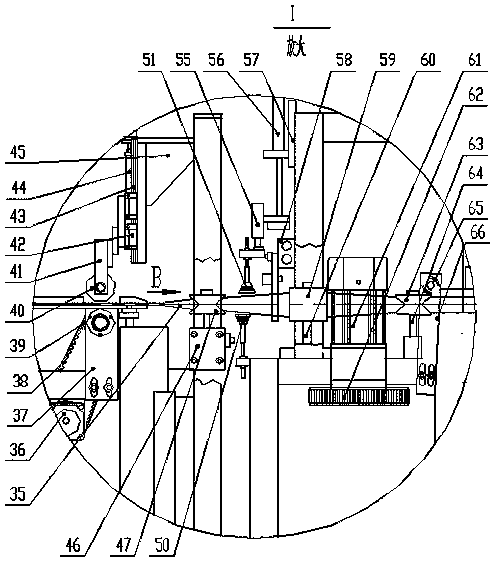

[0016]LED lamp tube automatic packaging line lamp tube packaging box forming machine, including a frame, a feeding device is arranged on the frame (1), and the feeding device includes a feeding bin bottom plate (5). An upper silo bottom plate reinforcement plate (6) is arranged beside the bottom plate (5), and a track (2) is arranged on the frame, and an open track bearing (3) is arranged on the side of the upper hopper bottom plate, and an open track bearing (3) An open track bearing backing plate (4) is arranged outside, a splint (7) is arranged on the upper end of the bottom plate (5) of the feeding bin, and a splint fixing plate (8) is arranged on the upper end of the splint (7). ) is provided with a fixed bracket (9) on the upper end, a screw rod (10) is provided on the side of the fixed bracket (9), a timing belt (11) is provided on the upper end of the screw rod (10), and the timing belt (11) is connected to There is a synchronous motor (12), a fixed rod (14) is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com