Crab processing apparatus and method

A processing device and crab technology, applied in packaging and other directions, can solve the problems of low production efficiency, high production cost, complicated operation, etc., and achieve the effects of high production efficiency, low processing cost and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

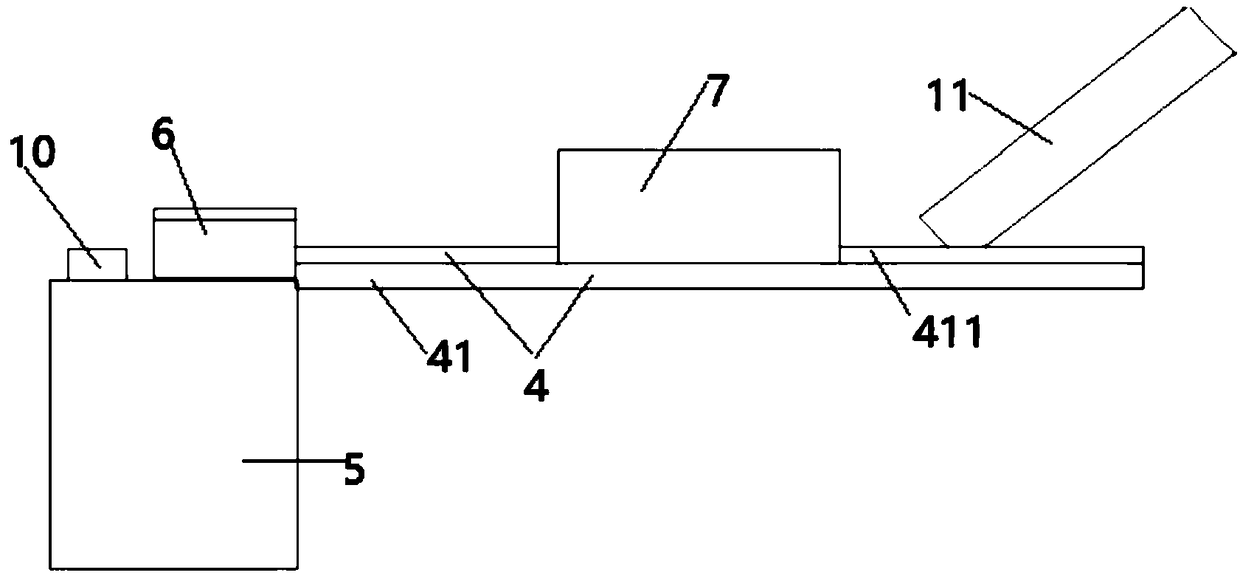

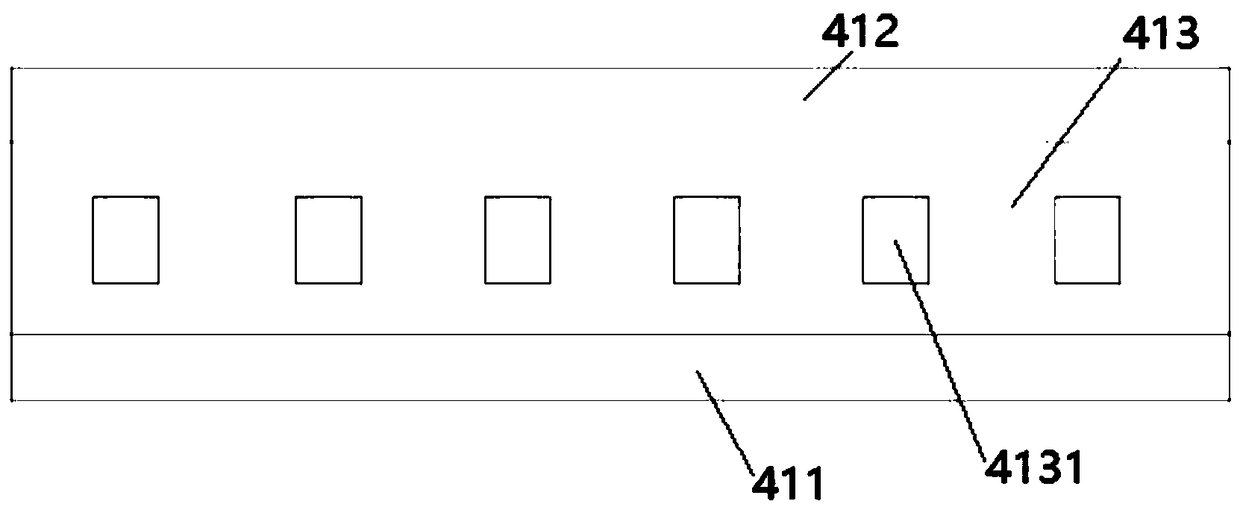

[0046] Such as figure 1 , Figure 5 The shown crab processing device includes a container 1 filled with crabs, a guide channel 11 connected to the container and inclined downward, a conveyor belt device 4 located below the guide channel, and a support frame near the discharge end of the conveyor belt device 5 and the packaging box 6 located on the support frame; the middle part of the conveyor belt device is provided with an air-conditioning cover 7, which is connected with the low-temperature constant temperature tank through an air inlet pipe, and the two ends of the air-conditioning cover are open, and an air-guiding channel is provided in the air-conditioning cover, and each guide The air passages are all connected with the air intake pipes, and the air outlets of each air guide passage are located on the inner surface of the cold air cover; the low temperature constant temperature tank is provided with a first electromagnetic valve 8, and the two ends of the packaging box...

Embodiment 2

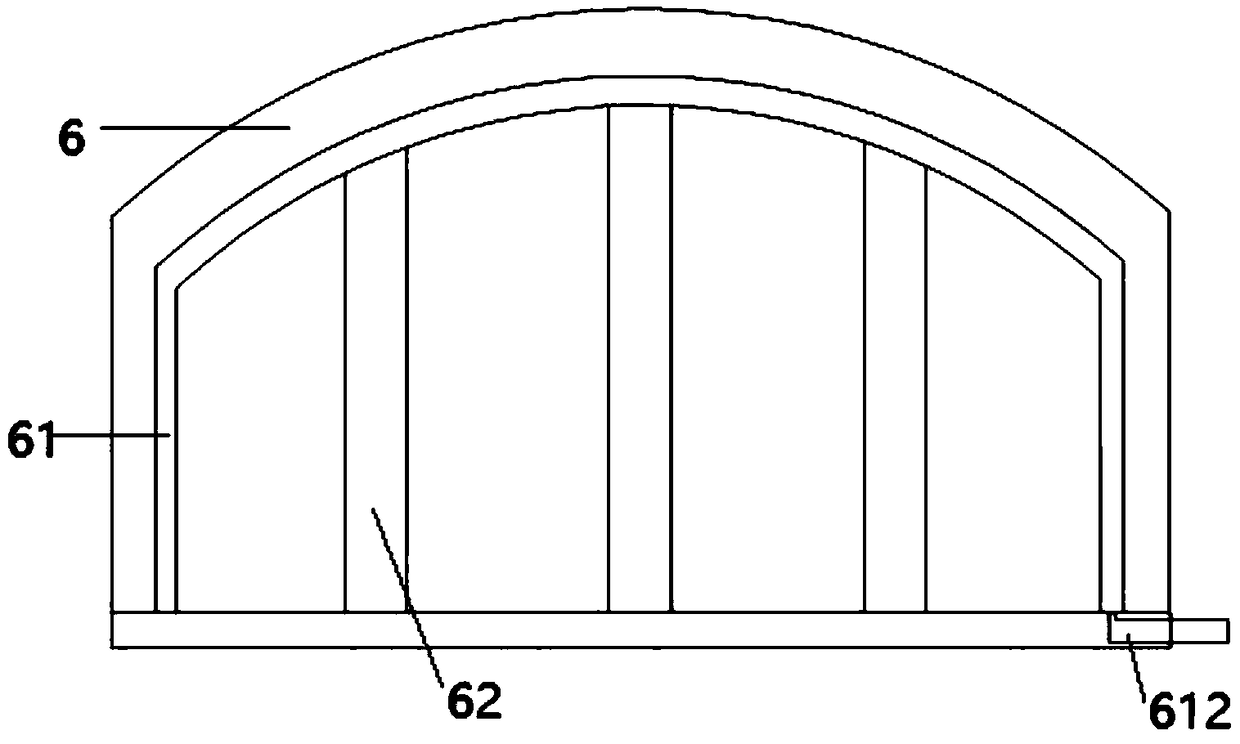

[0058] Embodiment 2 includes all structure and method parts of embodiment 1, such as figure 2 As shown, one end of the packing box is provided with three strip-shaped airbags 62, and each strip-shaped airbag is connected with the main airbag.

[0059] The controller of embodiment 1 controls the first solenoid valve to open to inflate the main airbag. The front part of the main airbag is provided with an n-shaped extension edge extending inward. After the main airbag expands, it presses the left and right sides of the crab, and the n-shaped extension Press the left and right front of the crab tightly, and the crab is packed and replaced with:

[0060] The controller controls the opening of the first electromagnetic valve to inflate the main airbag. The front part of the main airbag is provided with an n-shaped extension edge extending inward. After the main airbag is inflated, it presses the left and right sides of the crab, and the n-shaped extension edge presses the left fro...

Embodiment 3

[0062] Embodiment 3 includes all structure and method parts of embodiment 1, as Figure 5 , Image 6 As shown, the container of embodiment 3 includes an annular housing 201, a container cover 202 that is rotatably connected to the upper edge of the annular housing, and a funnel 203 located at the bottom of the annular housing; the funnel is connected to the upper end of the guide passage ; The outer wall of the annular shell is provided with a plurality of staggered through holes, the inner wall of the annular shell is provided with 6 openings 204, the container cover includes a circular top cover 205, and is located on the circular top cover An annular coaming plate 206 on the edge; the annular coaming plate surrounds the outside of the annular shell, a blower 207 is provided on the inner surface of the annular coaming plate, and a handle 208 is provided on the outer surface of the annular coaming plate; the blower is electrically connected to the controller.

[0063] The st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com