Circulating production process for oriented structural board from timber offcut

A production process and leftover technology, which is applied in the jointing of wooden veneers, the manufacture of thin wood chips, and wood processing equipment, etc., can solve the problems of OSB boards without flame retardancy and high content of toxic substances, and improve the use of Effects of longevity, improved performance, good adhesion and flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

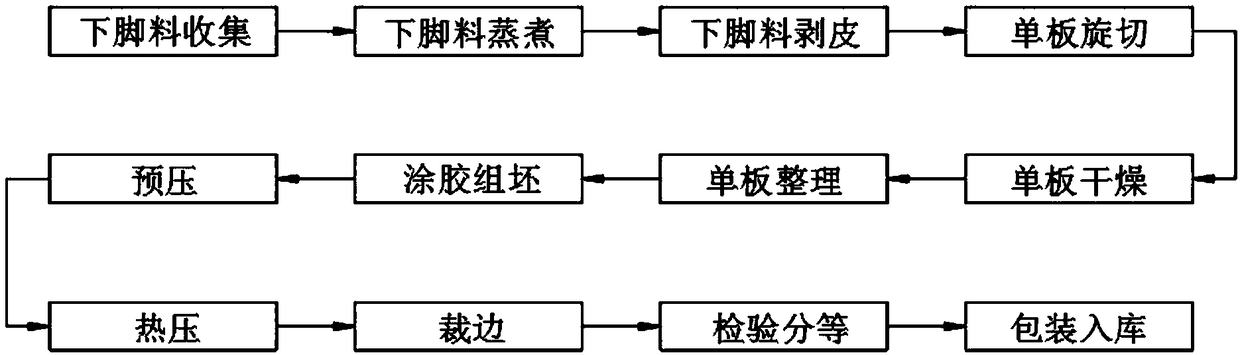

[0025] Example 1: See figure 1 , the present invention provides the circular production process of wood leftovers to produce Ozon board, comprising the steps of:

[0026] 1) Collection of leftovers: collect wood leftovers in a centralized manner and reserve them for later use;

[0027] 2) Cooking of leftovers: put the collected wood leftovers into a steamer for cooking, the cooking temperature is 80-90°C, and the cooking time is 25-35min;

[0028] 3) peeling of leftovers: peeling the wood leftovers that have been cooked, and removing the outer skin and necrotic parts of the wood;

[0029] 4) Veneer rotary cutting: Fix the treated wood scraps on the veneer rotary cutting device, start the machine, and the rotary knife will peel the wood scraps, and cut the raw materials into 6cm in length, 2cm in width and 0.1cm in thickness sheet, spare;

[0030] 5) Drying of the veneer: the finished sheet is dried by wet drying, so that the moisture content of the sheet is controlled at 1....

Embodiment 2

[0042] Example 2: see figure 1 , the present invention provides the circular production process of wood leftovers to produce Ozon board, comprising the steps of:

[0043] 1) Collection of leftovers: collect wood leftovers in a centralized manner and reserve them for later use;

[0044] 2) Cooking of leftovers: put the collected wood leftovers into a steamer for cooking, the cooking temperature is 80-90°C, and the cooking time is 25-35min;

[0045] 3) peeling of leftovers: peeling the wood leftovers that have been cooked, and removing the outer skin and necrotic parts of the wood;

[0046] 4) Veneer rotary cutting: Fix the treated wood scraps on the veneer rotary cutting device, start the machine, and the rotary knife will peel the wood scraps, and cut the raw materials into 6cm in length, 2cm in width and 0.1cm in thickness sheet, spare;

[0047] 5) Drying of the veneer: the finished sheet is dried by wet drying, so that the moisture content of the sheet is controlled at 3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com