Sander and sanding method

A sanding machine and sanding technology, applied in the direction of grinding machine parts, grinding/polishing equipment, machine tools suitable for grinding workpiece planes, etc., can solve problems such as action errors, and achieve high control accuracy and sanding. Good effect, stable output pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

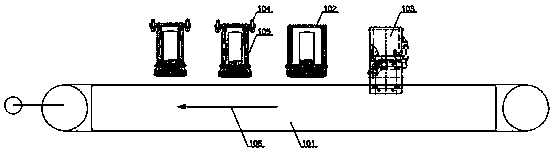

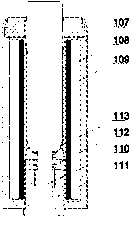

[0031] like figure 1 As shown, a sanding machine includes a conveying bed 101, a sanding device 102 and a detection device 103. The sanding device 102 is provided with a key-type sanding pad, and the key-type sanding pad includes a number of keys arranged in sequence, and the keys include The proportional electromagnet 104 and the pressing block 105 are connected to each other, and the detection device 103 includes a number of detection units corresponding to the keys. In the conveying direction 106 of the conveying bed, the keys and their corresponding detection units are located on the same straight line, and the detection unit includes at least one detection unit. The sensor that detects the passing of the board is a proximity switch or an infrared detection sensor. When a board passes under the sensor that detects the passing of the board, the sensor can detect it. Preferably, in this embodiment, the sensor that detects the passing of the board is a proximity switch.

[00...

Embodiment 2

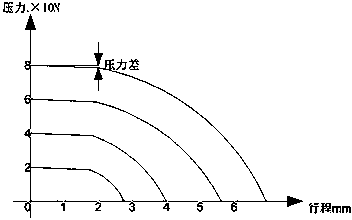

[0036] A sanding method includes the following steps: the sensor 222 in the detection unit for detecting the passage of the plate detects whether there is a plate passing; the proportional electromagnet of the key corresponding to the detection unit outputs the pressure of P*n / m, and P is the output pressure. The full value, n is the number of sensors that detect the passing of the plate, m is the total number of sensors, the pressure of the output P*n / m is controlled by inputting the current of I*n / m to the proportional electromagnet, and I is the proportional solenoid The current required when the iron outputs P.

[0037] like Figure 4 As shown, the same parts as in the first embodiment will not be repeated, the difference is that the key-type sanding pad in this embodiment includes ten keys, which are the No. 1 key 201, No. 2 key 202, No. 3 keys 203, 4 No. 204, No. 5 key 205, No. 6 key 206, No. 7 key 207, No. 8 key 208, No. 9 key 209 and No. 10 key 210 (only the pressing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com