Fertility-increasing type soil remediation system and remediation method thereof

A soil remediation and soil heating technology, applied in the field of fertilizer-enhancing soil remediation system and its remediation, can solve the problems of incomplete thermal desorption of soil, air pollution, uneven heating, etc., so as to eliminate soil nutrient loss and reduce environmental pollution. , the effect of uniform heating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

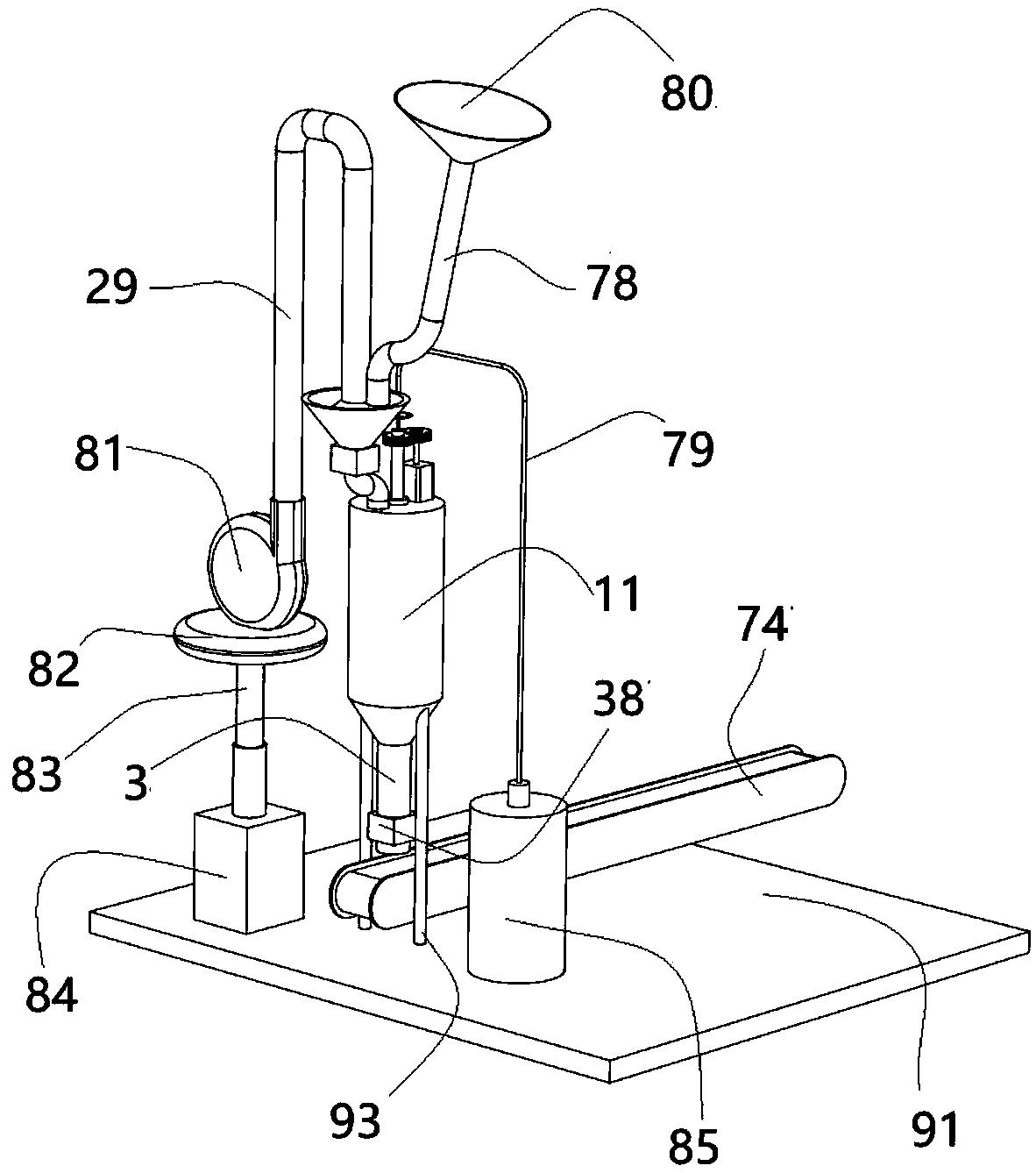

[0038] The present invention will be further described below in conjunction with the accompanying drawings.

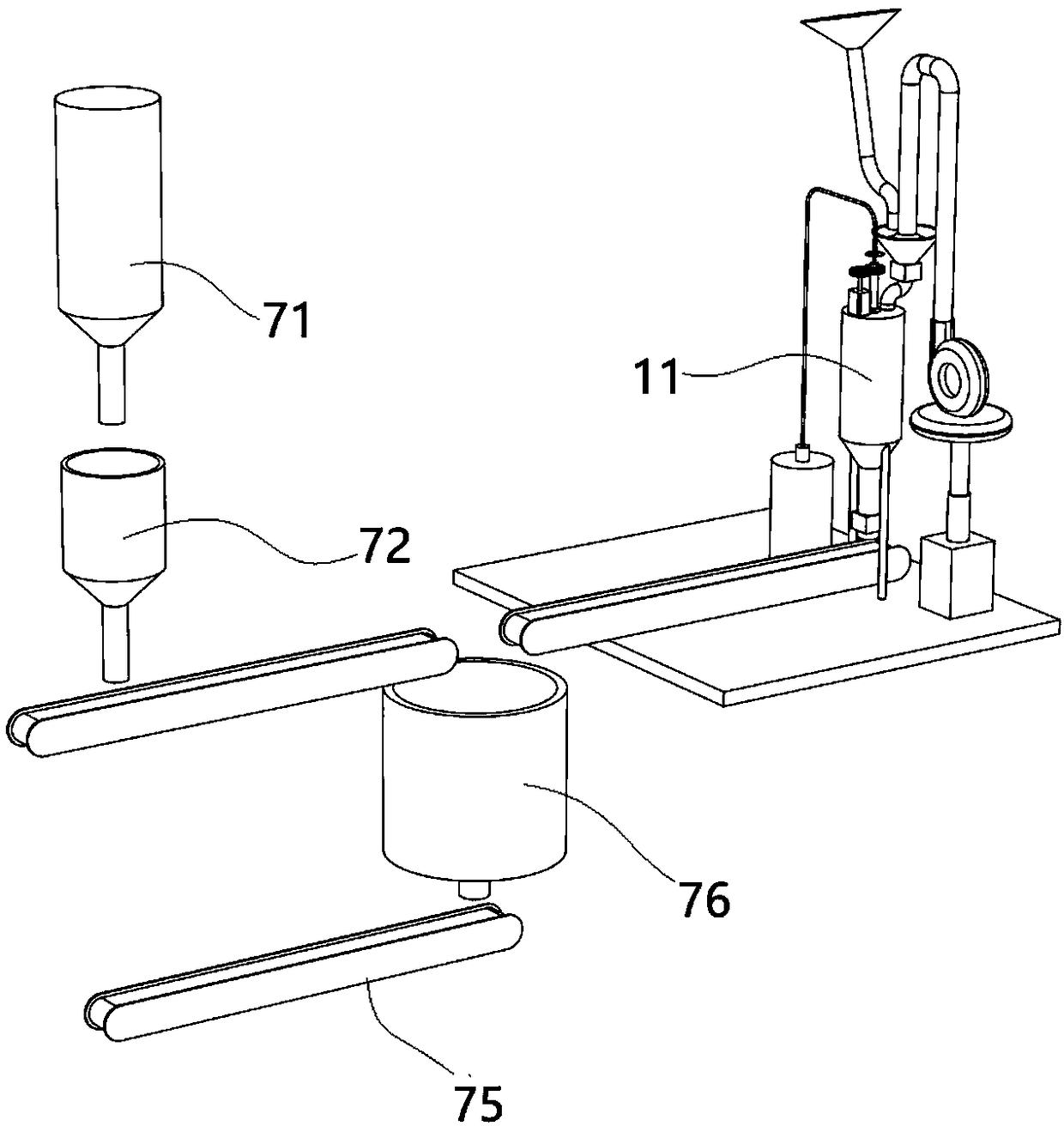

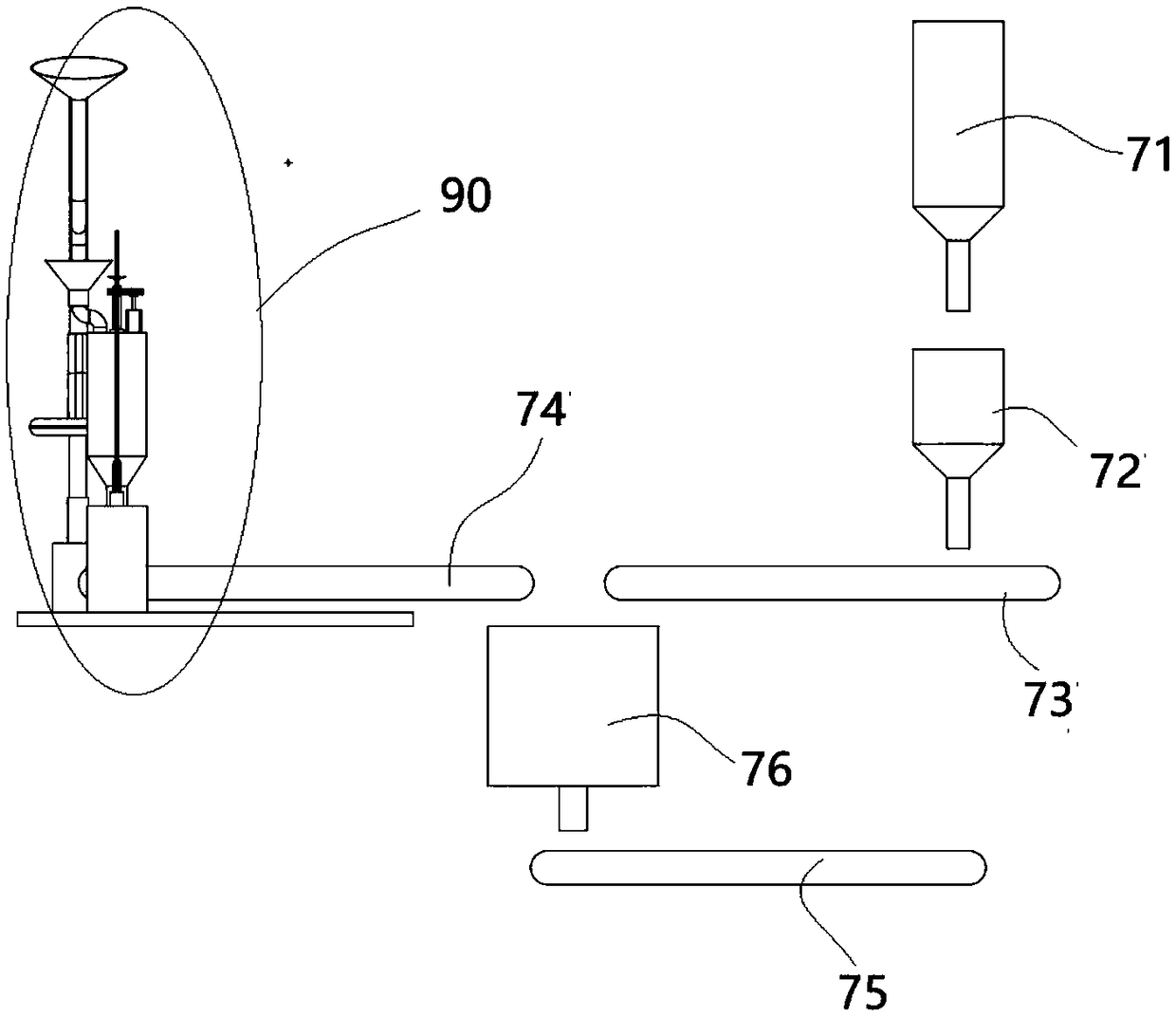

[0039] as attached Figures 1 to 11A kind of fertilization type soil remediation system shown, comprises soil thermal desorption unit 90, excrement fermentation unit 71, stirring dosing unit 72 and soil excrement mixing unit 76;

[0040] The soil source discharge end of described soil thermal desorption unit 90 is connected with the soil source feed end of described soil excrement mixing unit 76 by the first conveyor 74; The discharge end of described excrement fermentation unit 71 is connected with the stirring The feeding end of the dosing unit 72 is connected, and the discharge end of the stirring dosing unit 72 is connected with the ight soil feeding end of the soil and manure mixing unit 76 through the second transmission device 73, and the soil and manure mixing unit 76 The discharge end of is connected with the third conveying device 75.

[0041] The soil ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com