Method for selecting coal by using water medium swirler

A water medium, cyclone technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of rapid equipment wear, large maintenance, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

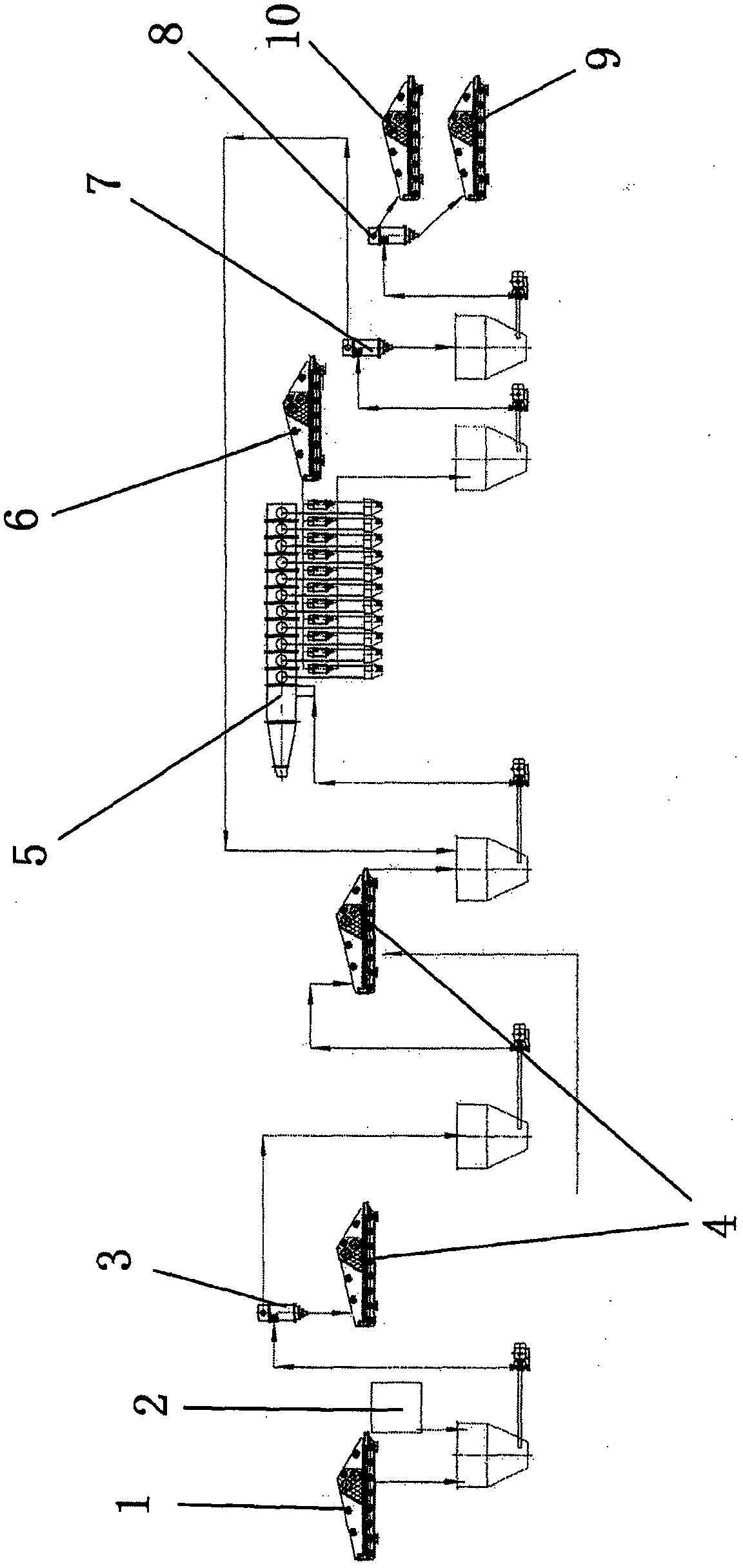

[0017] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

[0018] see figure 1 , a method for coal preparation of an aqueous medium cyclone comprising: 1 grading sieve, 2 crushers, 3 feeding boxes of the aqueous medium gangue discharging cyclone, 4 aqueous medium gangue discharging cyclone, 5 aqueous medium gangue discharging cyclone gangue dewatering screen of flow device, feeding box of 6 high-frequency linear desliming and grading vibrating screen, 7 high-frequency linear desliming and grading Coal slime classification and separation unit, 10 clean coal dehydration screen of fine coal and coarse coal slime classification and separation unit, 11 feeding box of water medium recovery cyclone, 12 water medium recovery cyclone, 13 gangue cyclone in water medium The feeding box of the device, 14 gangue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com