Spiral pushing grass pressing machine

A technology of screw propulsion and screw propeller, which is applied in the direction of land preparation machinery, agricultural machinery and implements, etc. It can solve the problems of inaccurate control, slipping, and difficult vehicle control, etc., and achieve simple operation, high structural strength, and adaptability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

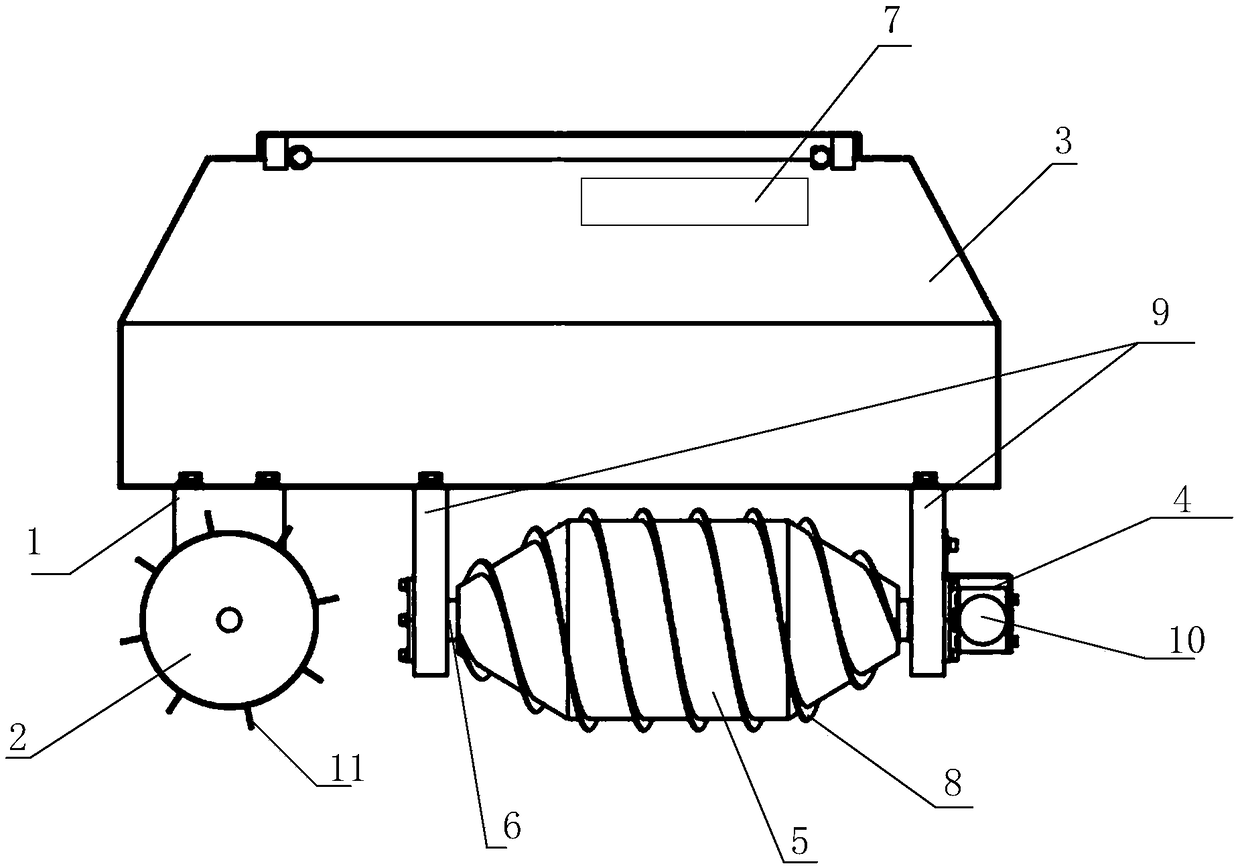

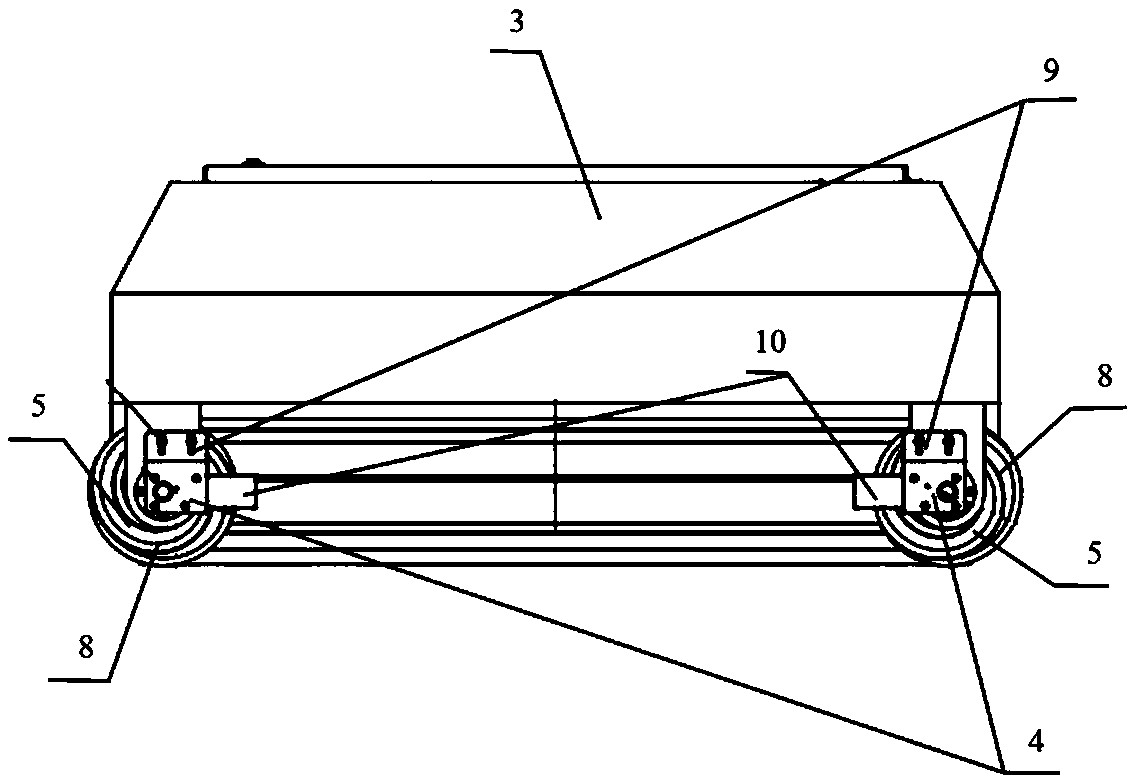

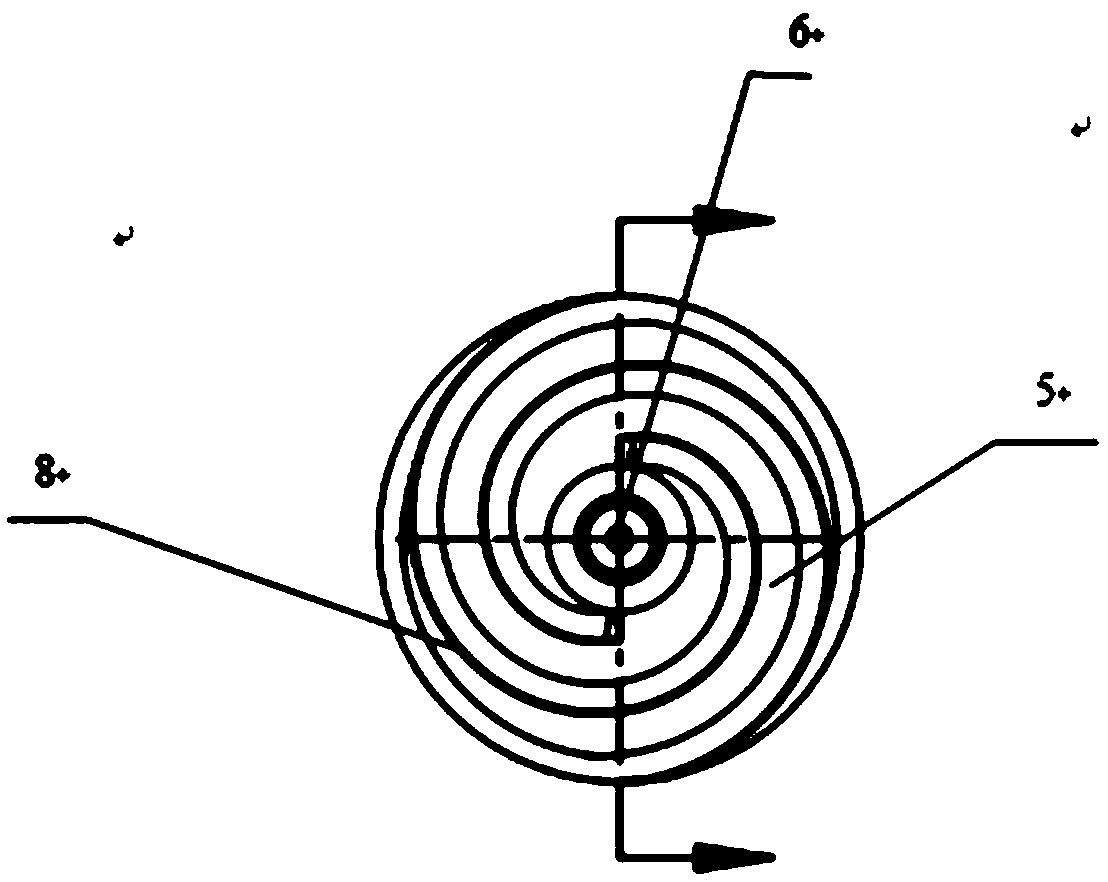

[0028] Such as figure 1 and figure 2 As shown, the present invention provides a screw-propelled grass trimmer, which includes a fuselage 3, an operating structure fixed to the fuselage 3, and a propulsion structure, wherein the operating structure includes a pressing mechanism connected to the fuselage 3. Grass wheel support 1 and the grass-pressing round roller 2 assembled on the grass-pressing wheel support 1, the operation structure is fixed on the fuselage 3 with screws for example, the grass-pressing round roller 2 is provided with the grass-pressing wheel hobbing 11, and the grass-pressing wheel Hobbing 11 is for example blade, blade, screw thread etc., and this grass-pressing wheel hobbing 11 helps to press grass, and this grass-pressing wheel hobbing 11 has a certain height, and the height of grass-pressing wheel hobbing 11 is preferably greater than 10mm; The structure includes a pair of screw propellers and two motors 10 connected with the pair of screw propellers,...

Embodiment 2

[0036] refer to figure 1 and figure 2 , the present invention also provides a kind of operation method that is used for the screw propulsion lawn mower of embodiment 1, and this operation method comprises:

[0037] The motors 10 on both sides start to rotate in the opposite direction, driving the screw propulsion wheel 5 to rotate in the opposite direction, and the screw thread 8 of the screw propulsion wheel rotating in the opposite direction is deeply embedded in the soil and strongly rubs against the soil to generate forward propulsion. Make the car body move forward, and in the process that the car body advances, the grass stem is pressed into the soil by pressing the grass and rolling 2. The steering of the car body is realized through the propulsion structure. Specifically, the control system 7 sends a steering signal to the motor 10, and the motor 10 slows down the speed of the screw propulsion wheel 5 on this side, and speeds up the speed of the other side, so that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com