Stator permanent-magnet thin-type bearingless switch reluctance machine

A switched reluctance motor, sheet type technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit, electromechanical device, etc., can solve the problem of high speed and high power density, high critical speed and axial Long length and other problems, to achieve the effect of short axial length, simple control, and less driving circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

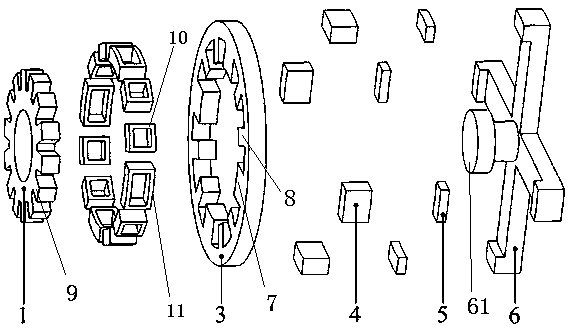

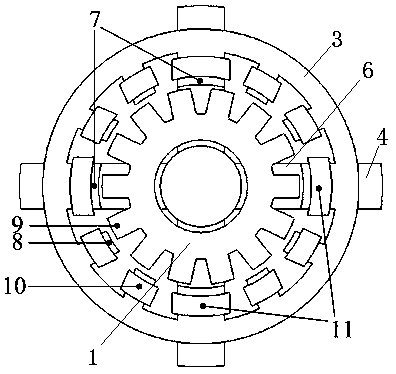

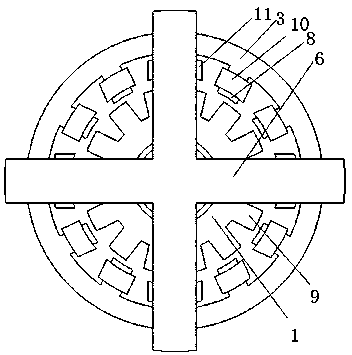

[0025] Such as Figure 1~6 A stator permanent-magnet laminar type bearingless switched reluctance motor shown includes a stator and a rotor 1, the side of the rotor 1 is provided with 12 rotor teeth 9, and the stator is composed of a stator core 3, a torque winding 10. The suspension winding 11, the first magnetic bridge 4, the permanent magnet 5, and the second magnetic bridge 6 are stacked in the axial direction. The stator core 3 is made into a ring, and the inner ring is arranged in the x direction and the y direction There are a total of four suspension teeth 7, two torque teeth 8 are evenly arranged on the inner ring of the stator core 3 between two adjacent suspension teeth 7, and the suspension winding 11 and the torque winding 10 are respectively wound on the suspension teeth 7 and on the torque tooth 8; the width of the suspension tooth 7 is greater than the width of the torque tooth 8, and the width of the suspension tooth 7 is greater than one pole pitch of the mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com