Method for identifying damage and quantitatively analyzing damage degree of main girder of bridge erecting machine

A damage degree, quantitative analysis technology, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve problems such as structural damage to the main girder of the bridge erection machine, safety accidents, and failure to detect in time, and achieve economical and reliable results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings. The protection scope of the present invention is not limited to the embodiments, and any changes made by those skilled in the art within the scope defined in the claims also belong to the protection scope of the present invention.

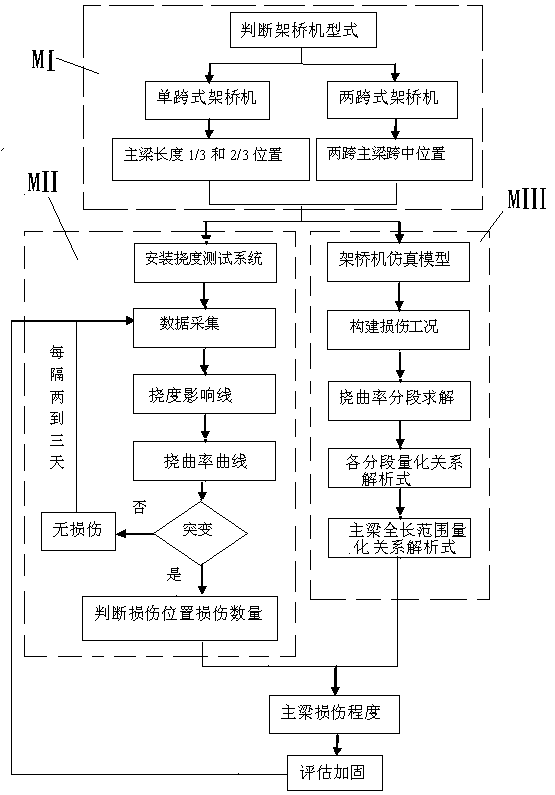

[0028] The method for identifying damage to the main girder of the bridge erecting machine and quantifying the damage degree of the present invention is to perform quantitative analysis on whether the main girder of the bridge erecting machine is damaged, the location of the damage, and the degree of damage on the basis of the deflection monitoring data obtained during the operation of the bridge erecting machine. Such as figure 1 As shown, based on the status quo of the main girder support changing at any time during the operation of the bridge erecting machine, the main girder structure type judgment module (MI), dama...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com