Visual inspection system and method for temperature controller casing

A technology of visual inspection and temperature controller, which is applied in the field of visual inspection system, can solve the problems of slow detection speed, missing detection, and wrong detection of the shell, and achieve the effect of improving detection efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

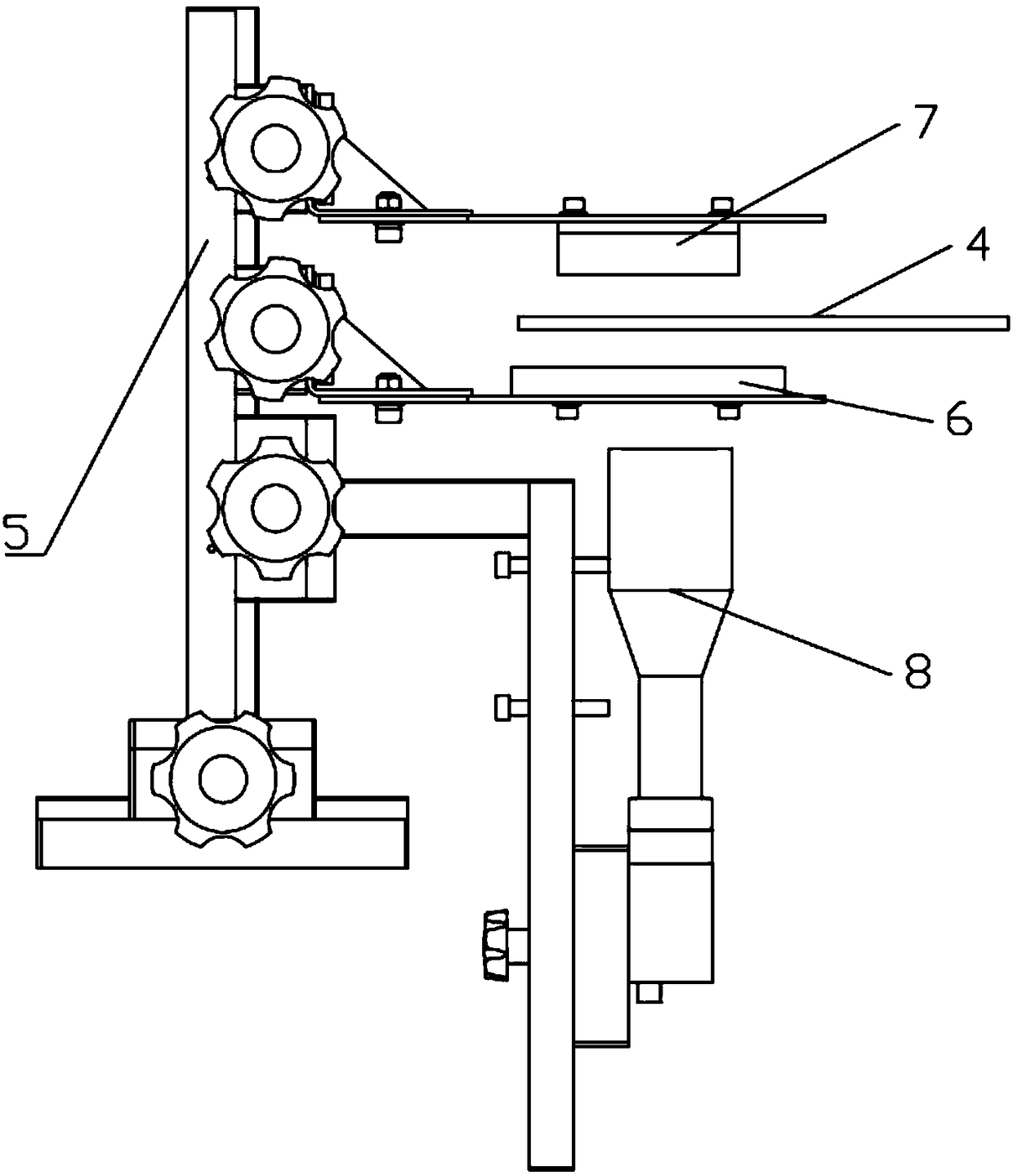

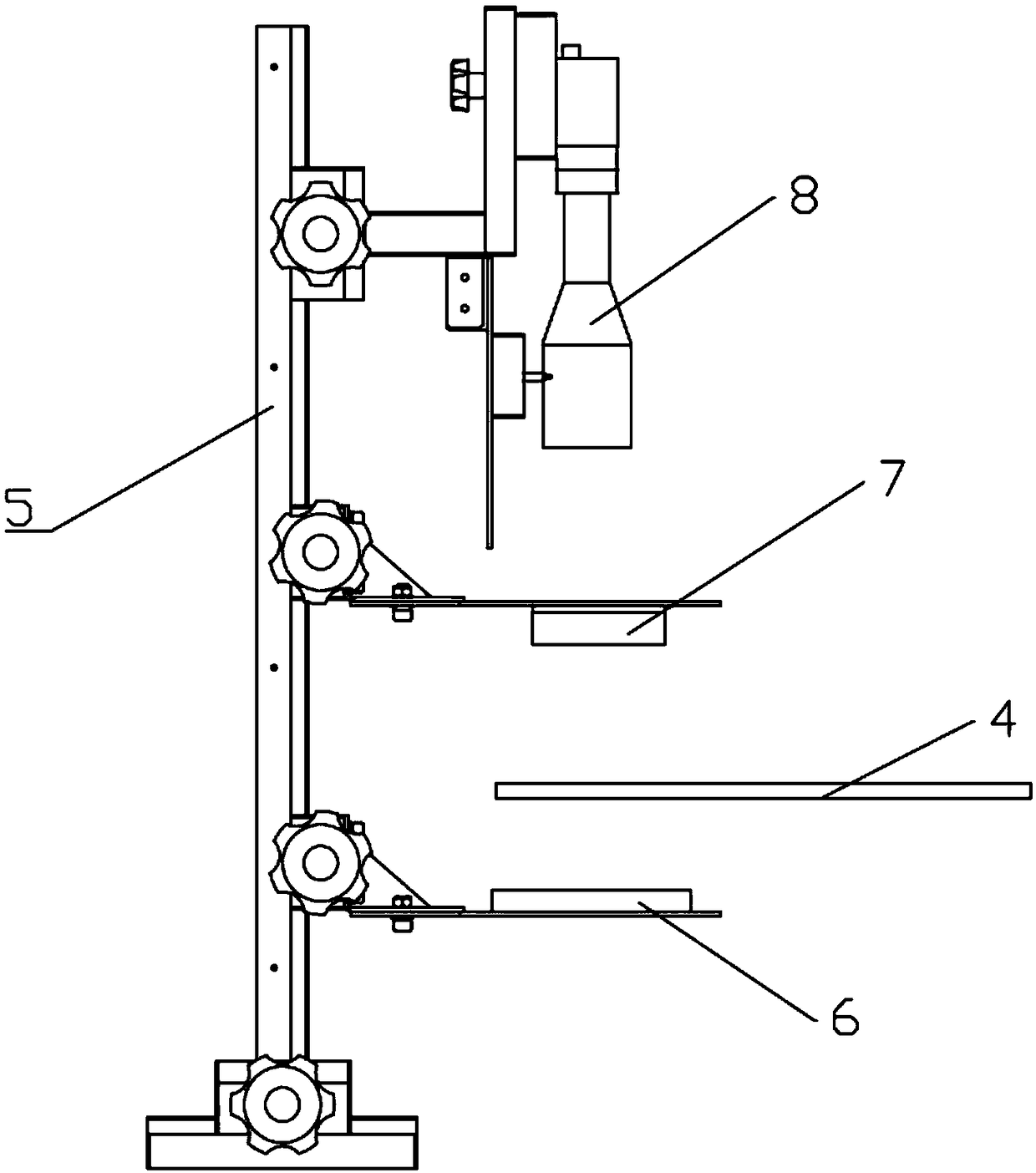

[0037] Embodiment 1, with reference to figure 1 , figure 2 , image 3 and Figure 6 ,in Figure 6 Among them, the upper figure is the top 9 of the thermostat housing, and the lower figure is the bottom 10 of the thermostat housing. A visual detection system for a thermostat housing, comprising: a glass turntable 4, a first station 1, a second station 2 and a third station 3, the first station 1, the second station 2 and the third station The bits 3 are respectively set along the edge of the glass turntable 4;

[0038] The first station 1, the second station 2 and the third station 3 are all provided with a fixed frame 5, a camera 8 and a machine vision light source, and the machine vision light source and the camera 8 are all arranged in the fixed frame 5, wherein the first The cameras 8 of the first station 1 and the second station 2 are all arranged below the glass turntable 4, and towards the glass turntable 4, and the camera 8 of the third station 3 is arranged above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com