Pressing plate motion balance detection device and detection method thereof

A technology of balance detection and movement, which is applied in the direction of static/dynamic balance test, measuring device, machine/structural component test, etc. It can solve problems such as inability to guarantee pressing pressure, high plate defective rate, and increased production cost. Achieve the effects of ingenious structure, high detection accuracy and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

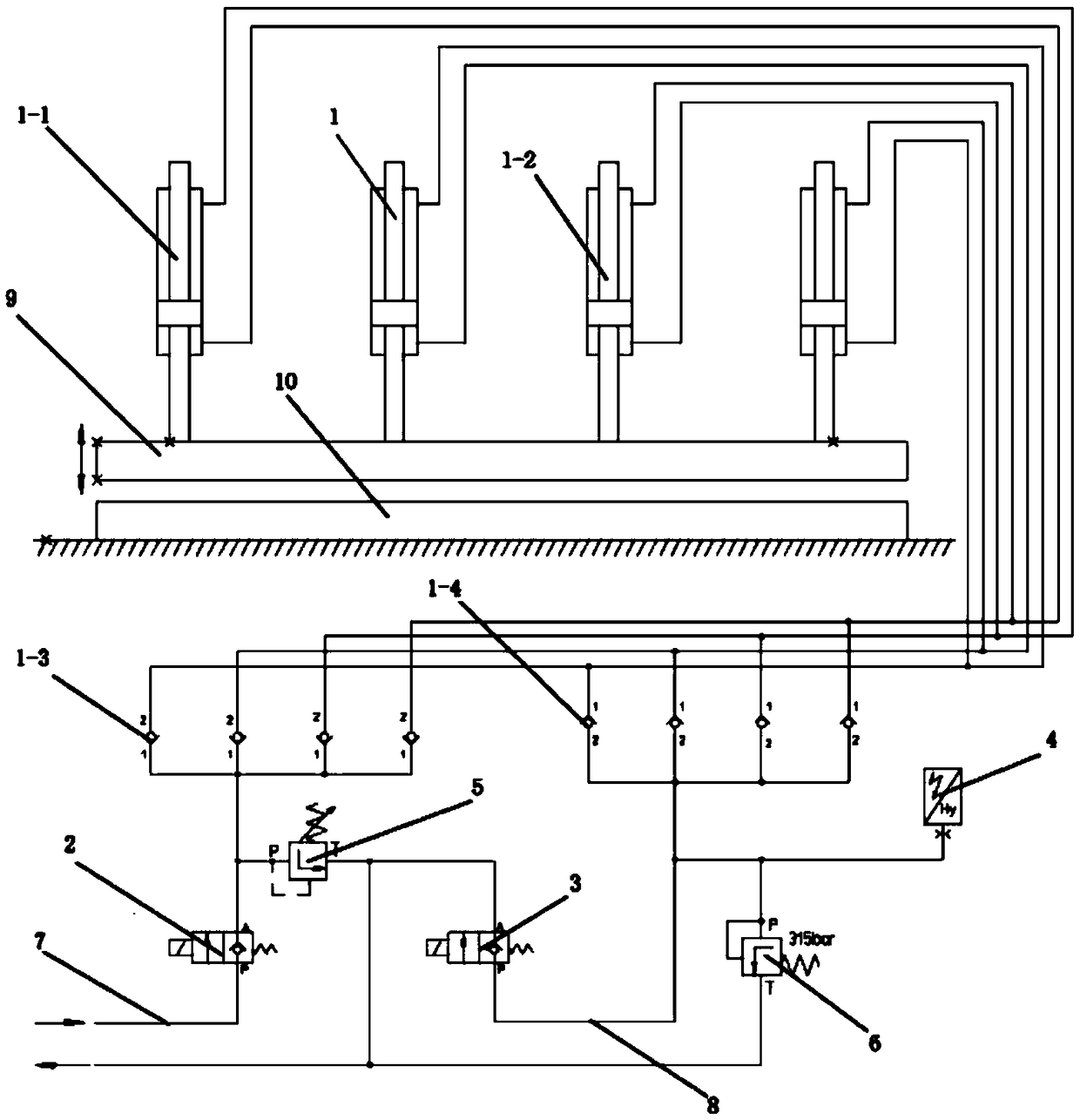

[0033] See figure 1 with figure 2 , the pressure plate motion balance detection device of the present embodiment includes an oil cylinder assembly 1, a pressurization solenoid valve 2, a pressure relief solenoid valve 3, a pressure sensor 4, a pressurization pressure limit valve 5, a safety valve 6, an oil inlet pipe 7 and an oil outlet pipe 8 .

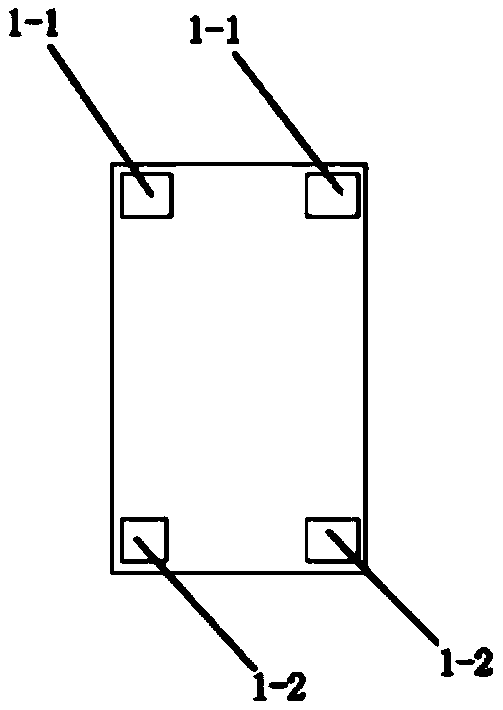

[0034] The oil cylinder assembly 1 is provided with two groups. The cylinder assembly 1 includes a first double-rod cylinder 1-1 and a second double-rod cylinder 1-2. The cylinder blocks of the two first double-rod cylinders 1-1 and the two second double-rod cylinders 1-2 are fixed relative to the ground. The bottoms of the piston rods in the lower cavity of the two first double-rod cylinders 1-1 and the two second double-rod cylinders 1-2 are respectively installed on the four corners of the movable platen 9, and the first cylinder assembly 1 of each group One pair of rod-out cylinders 1-1 and the second double-rod cylinder 1-2...

Embodiment 2

[0047] This embodiment is basically the same as Embodiment 1, the difference is that only one group is provided for the cylinder assembly 1, and the bottoms of the piston rods in the lower cavity of the first double-rod cylinder 1-1 and the second double-rod cylinder 1-2 are respectively It is installed on one group of diagonal corners of movable platen 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com