Underwater blasting construction method

A construction method and filling technology, which is applied in blasting and other directions, can solve problems such as inability to set up an above-water construction operation platform, broken pipes, and difficult construction, and achieve the effect of large-scale underwater blasting operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

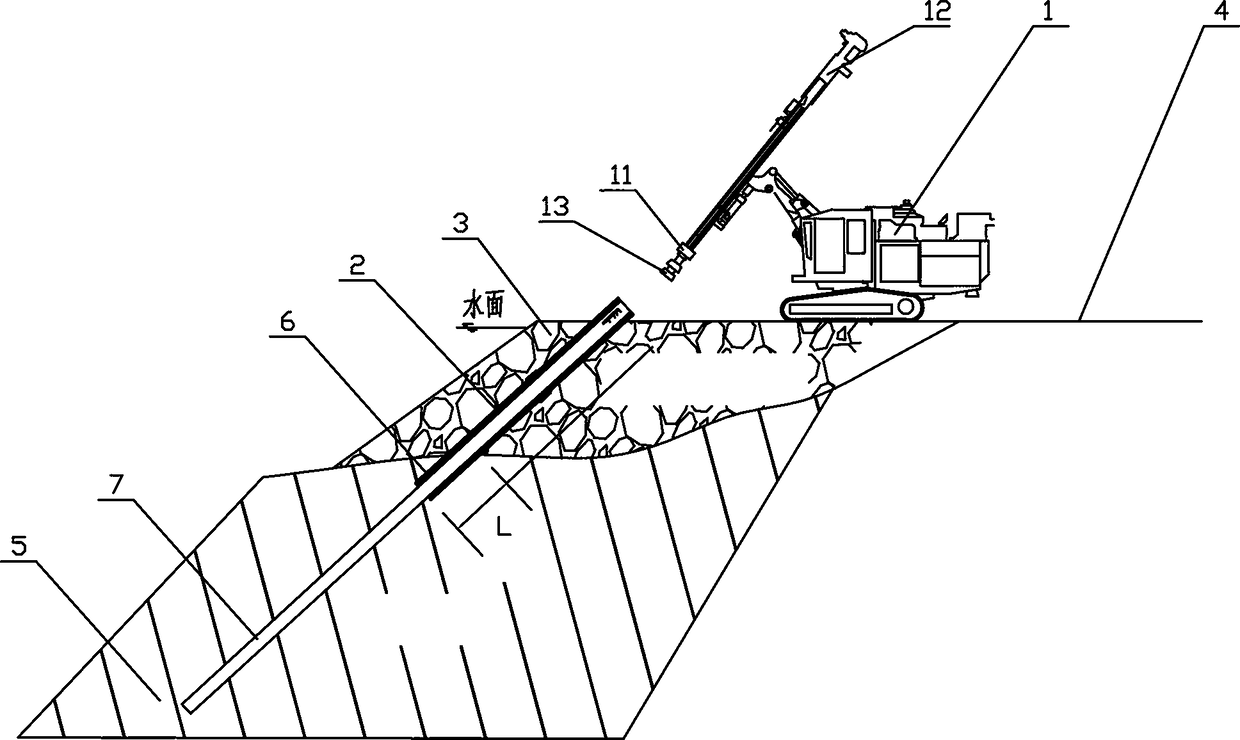

[0035] Such as figure 1 Among them, an underwater blasting construction method, comprising the following steps:

[0036] s1. Fill the underwater blasting site with the underwater filling body 3 above the water surface to form a construction platform; The water surface is above 50cm.

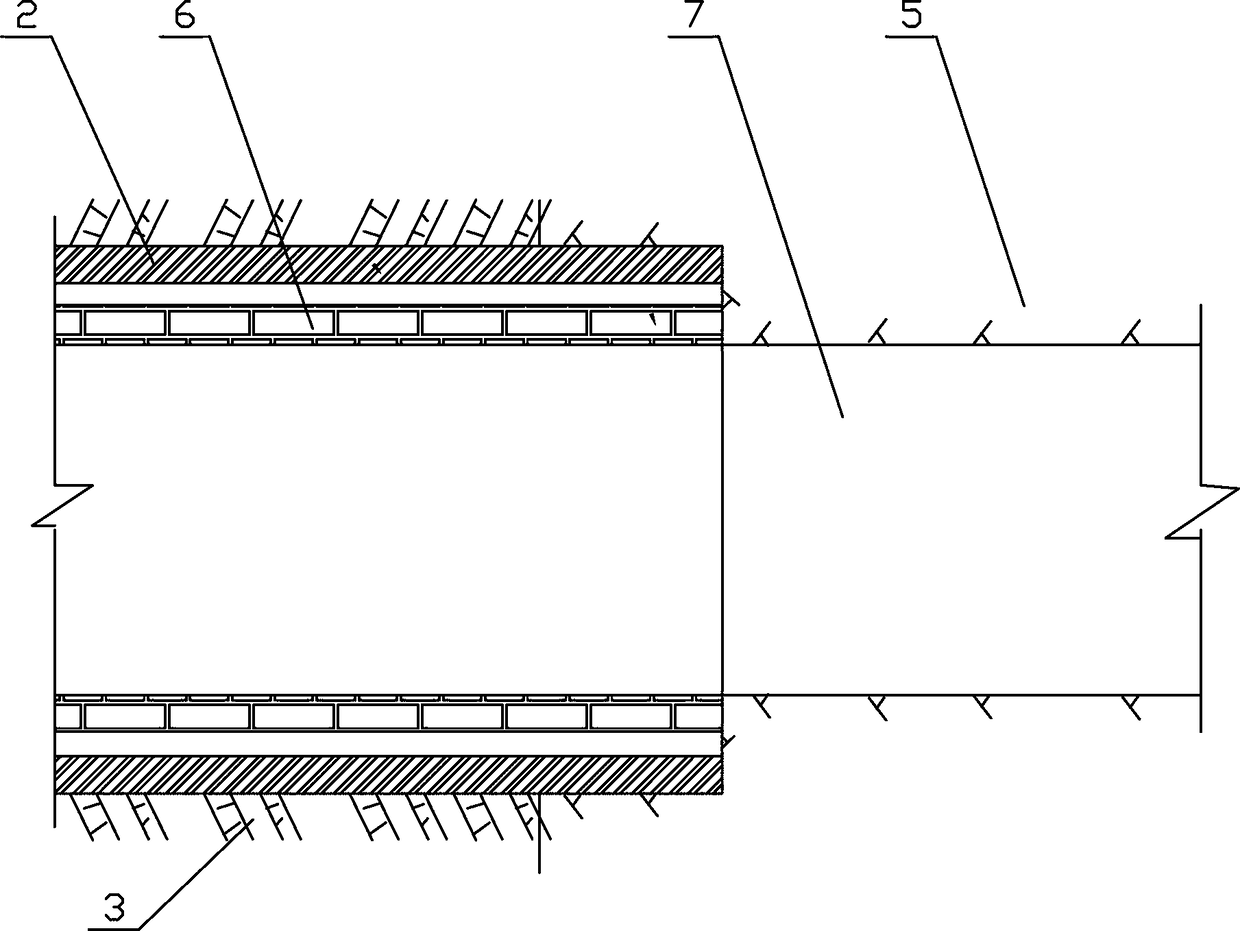

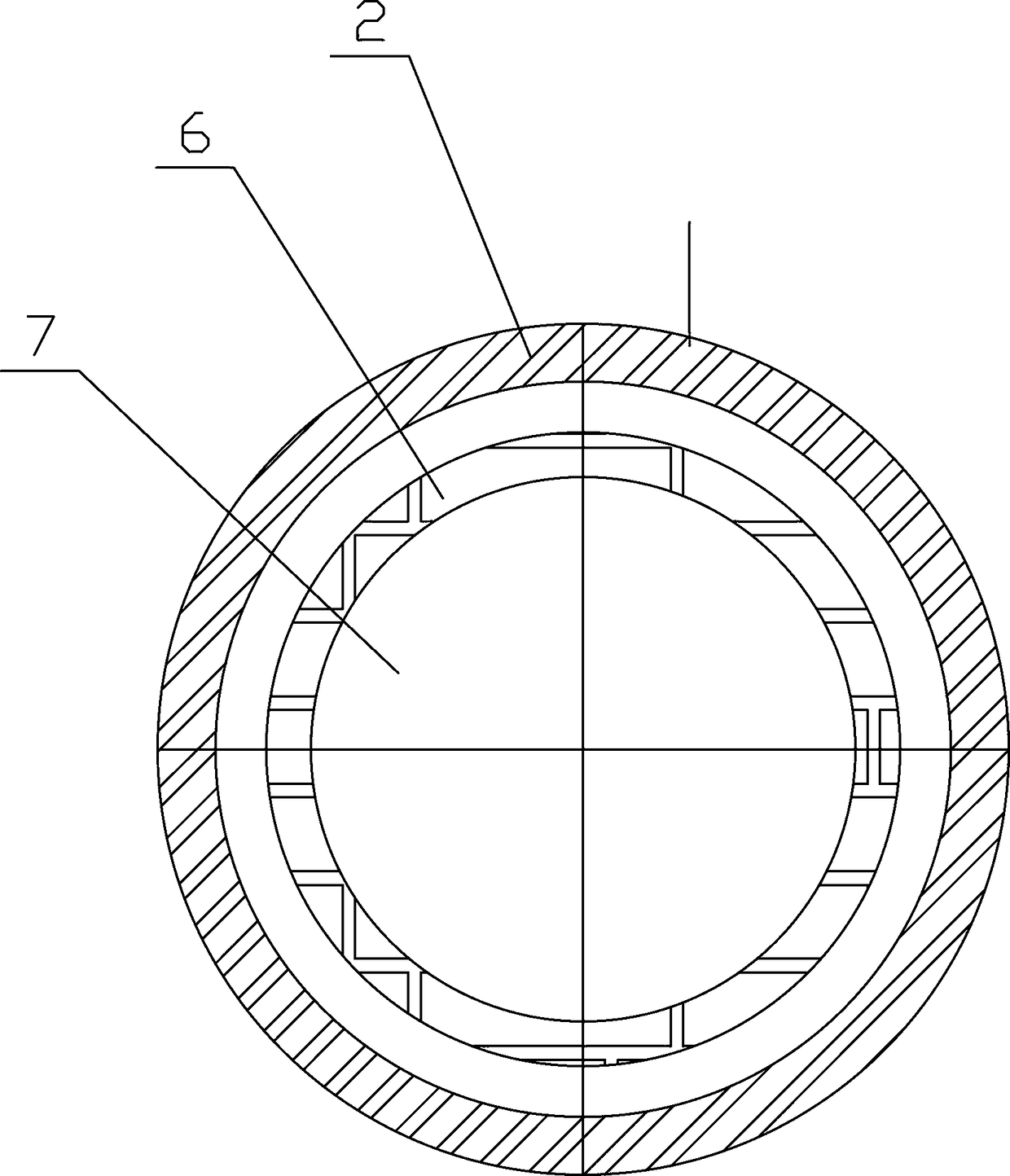

[0037] s2. Use the down-the-hole drilling machine 1 to follow up the steel casing 2 to form a hole; preferably, the down-the-hole drilling machine 1 in this example is a high-pressure down-the-hole drilling machine, and the preferred model is CM351. In a preferred solution, when the underwater filling body 3 is drilled, an eccentric drill bit 13 is used to drill the underwater filling body 3, and after drilling into the bedrock 5, an ordinary drill bit is used to drill into a hole. The CM351 type drill is refitted as a tube drilling rig to use the eccentric drill bit to lower the steel casing to form holes in the slag filling body or in the water. When drilling, first use a low wind pressure i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com