Low-cost damping potassium nitrate transfer container

A technology for transshipment containers and potassium nitrate, which is applied in the direction of preventing mechanical damage, such as containers, containers, bottles/container caps, etc. It can solve the problems of maintenance costs and lose the advantages of origin, and achieve the effect of low cost and improved sealing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

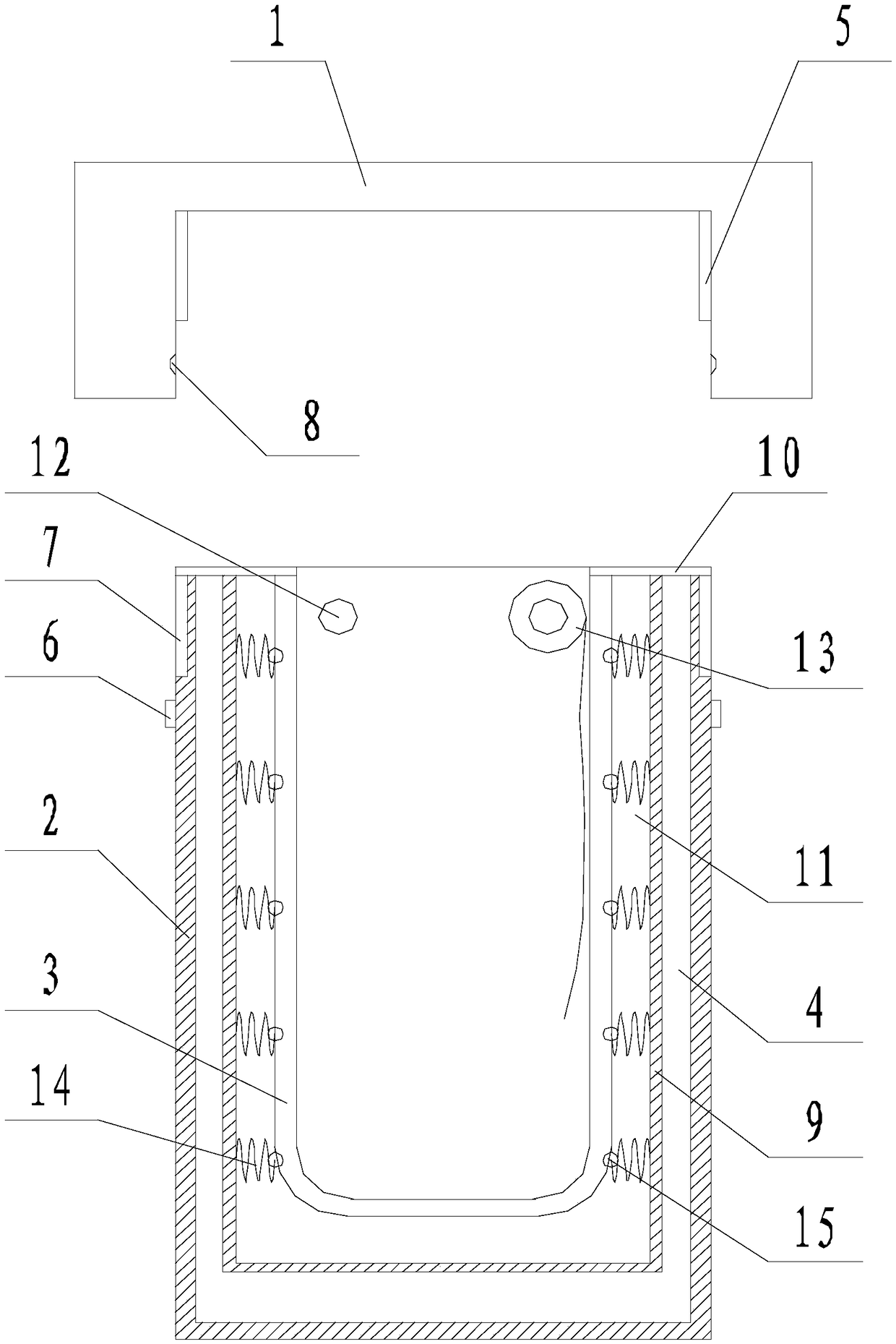

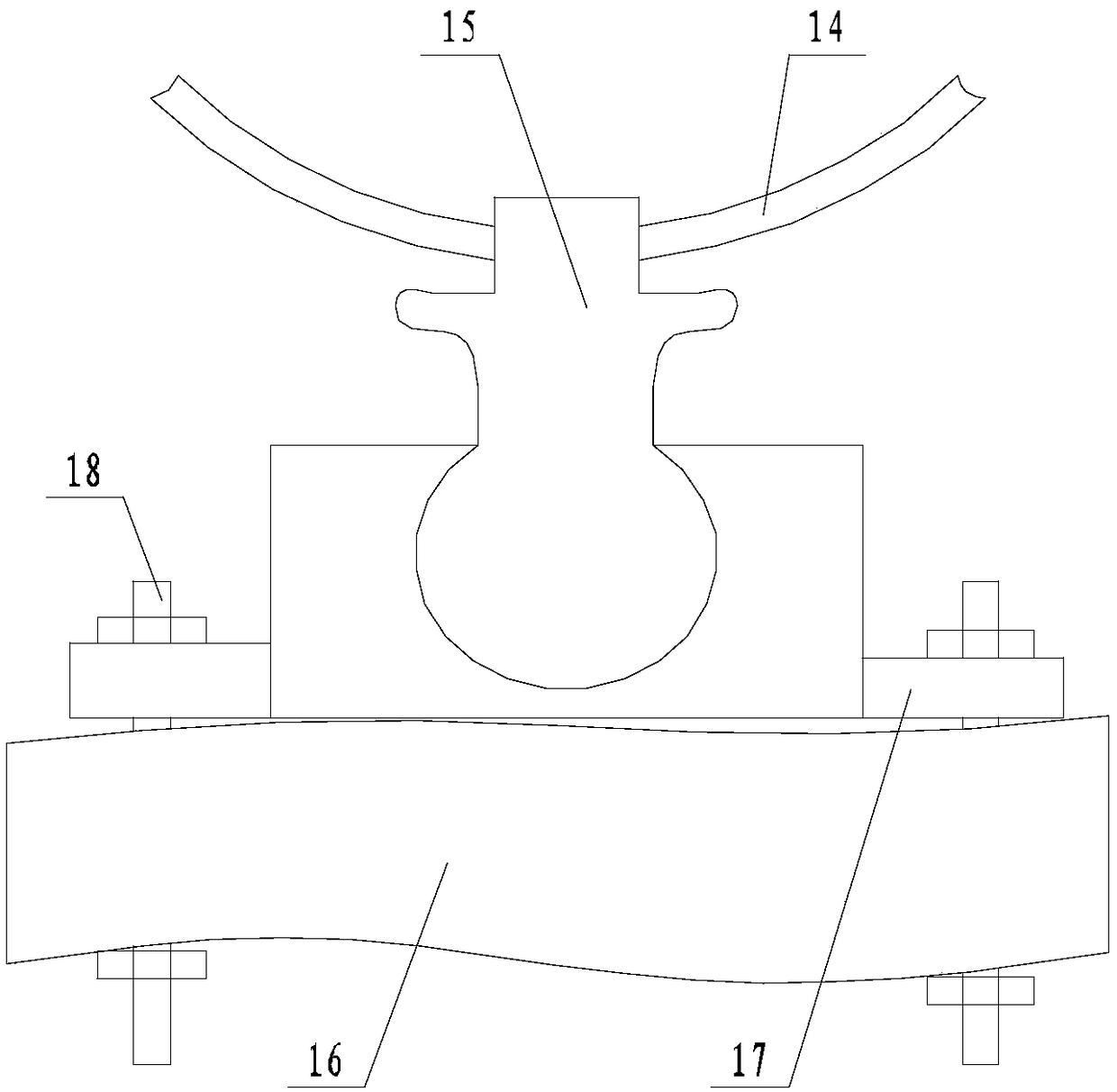

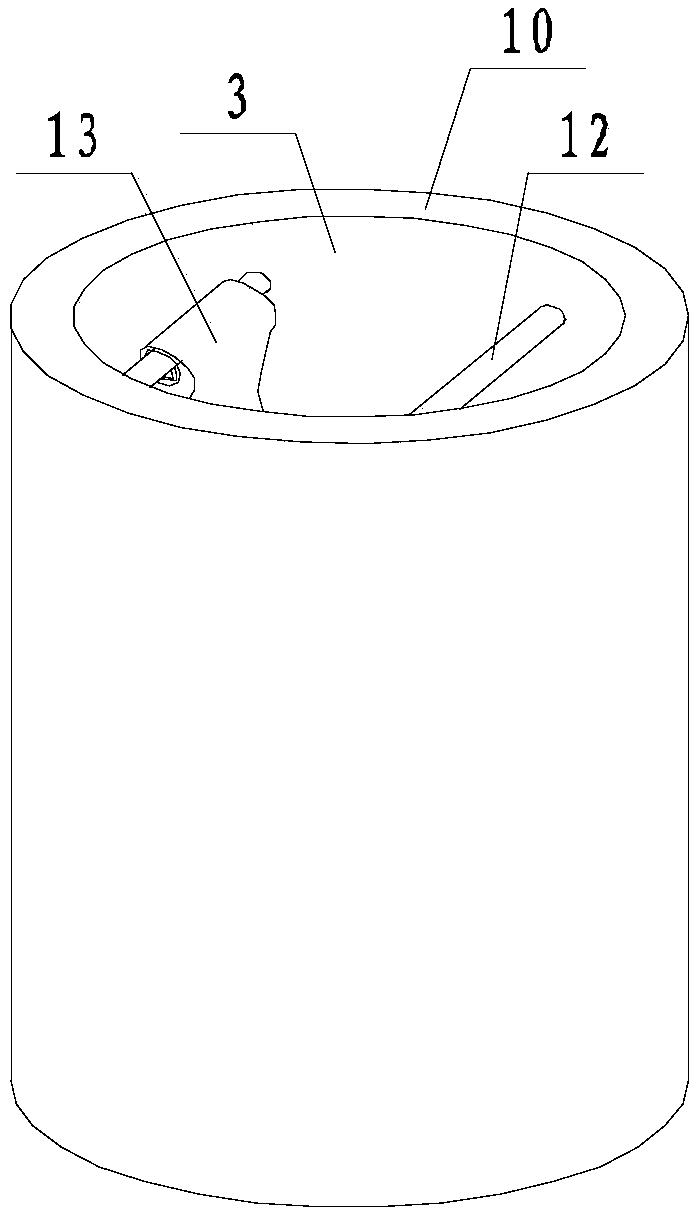

[0028] Such as figure 1 and figure 2 A kind of low-cost shock-absorbing type potassium nitrate transfer container shown, comprises container body, cover 1, and described container body comprises shell 2, isolation layer 9, liner 3 that distribute in sequence from outside to inside, and described shell 2, The insulating layer 9 and the inner container 3 are fixedly connected at the top by the mounting plate 10, the top of the inner container 3 is open, and the outer shell 2, the insulating layer 9, and the mounting plate 10 are jointly surrounded to form the first isolation chamber 4. The liner 3, the isolation layer 9, and the mounting plate 10 jointly form a second isolation cavity 11, the first isolation cavity 4 is filled with ceramsite, the second isolation cavity 11 is filled with silicon dioxide, and the outer shell 2 is composed of Made of wood, the inner tank 3 is made of rubber; a number of elastic bodies 14 are arranged in the second isolation chamber 11, one end o...

Embodiment 2

[0030] Such as Figure 1 to Figure 3 The shown arc radius of the section of the groove 8 is equal to the radius of the rubber sealing ring 6, and the central angle of the section of the groove 8 is 120-150°. An O-ring groove is provided on the surface of the housing 2, and the rubber sealing ring 6 is located in the O-ring groove. Two shafts 12 parallel to each other are fixed inside the liner 3 , and the two shafts 12 are symmetrically distributed along the axis of the liner 3 , and one of the shafts 12 is sleeved with a roll-shaped diaphragm 13 . The shaft 12 is 3 to 5 cm away from the open end of the top of the liner 3 . The diaphragm 13 is made of polypropylene material.

[0031] Preferably, the rubber used to make the liner 3 is natural rubber with a thickness of 5 cm. It is convenient for direct and stable connection with bolts and provides sufficient thickness for bolts.

Embodiment 3

[0033] On the basis of any of the above embodiments, a more preferred embodiment is that the weight ratio of each particle size in the ceramsite is: 20% of the ceramsite with a particle size of 5mm, 50% of the ceramsite with a particle size of 8mm, and 50% of the ceramsite with a particle size of 10mm. Ceramsite 30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com