Linear array camera with high frame rate based on area array image sensor and implementation method thereof

An image sensor and industrial camera technology, which is applied in image communication, color TV parts, TV system parts, etc., can solve the problems of insufficient resolution coverage and high integration cost of line scan detection systems, and achieve rich models and high The effect of frame rate and high line scan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below with reference to the accompanying drawings and the embodiments thereof, but the protection scope of the present invention is not limited to the scope described in the embodiments.

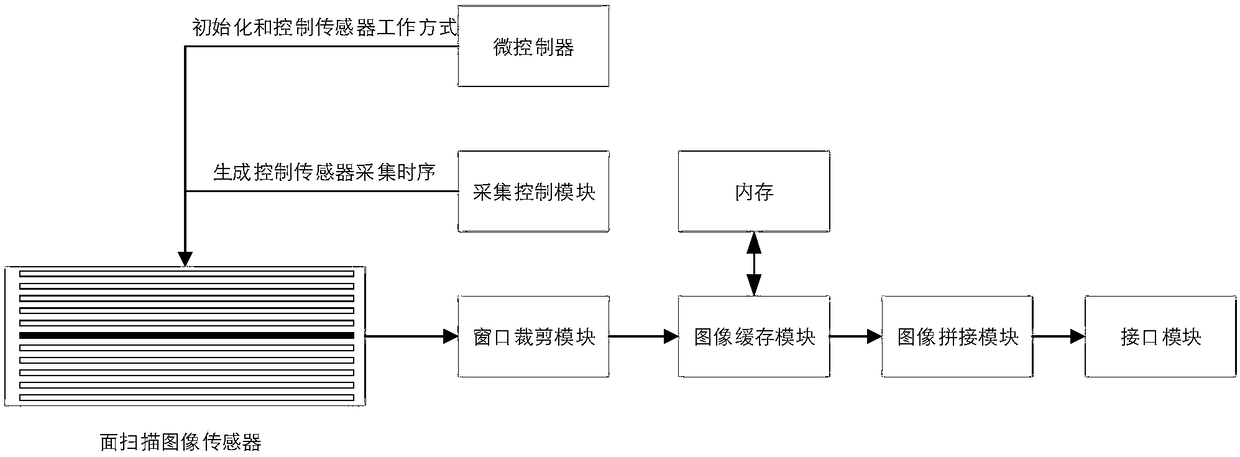

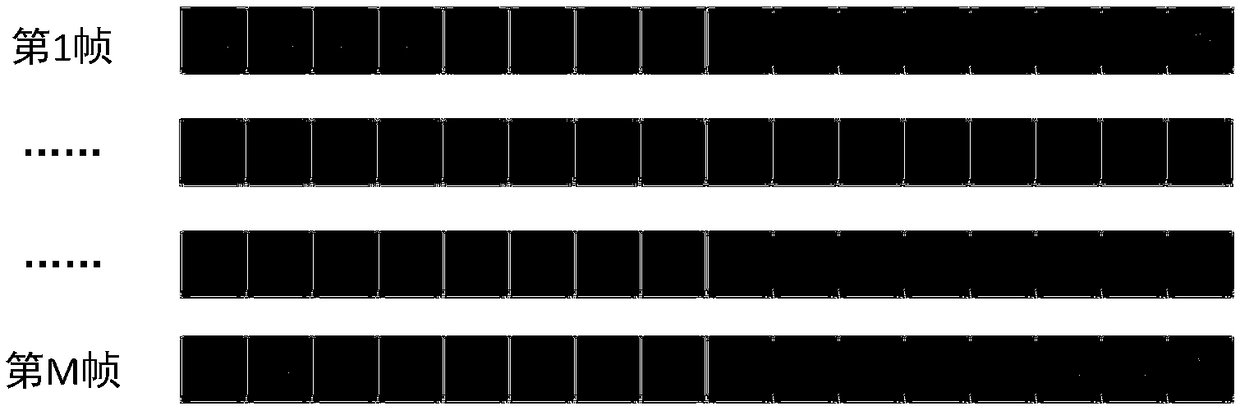

[0032] The invention provides a method for realizing a line-scan industrial camera by using an area scanning image sensor, and provides a corresponding structure of the industrial camera.

[0033] Line scan cameras in industrial applications have high requirements for scanning frame rates. The existing area scan cameras are packaged, and the scan frame rates that can be achieved are very limited. This is because the existing area scan cameras, which The amount of data is large and it is only necessary to cache a large amount of data and also need to transmit these data in time, so the improvement of frame rate is severely limited, which also limits the application of area scan cameras to the line array field by those skilled in the art....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com