Wastewater collection and connection fixation device and method for wine brewing wastewater sampling

A technology for connecting devices and fixing devices, which is applied in the direction of sampling devices, measuring devices, sampling, etc., can solve problems such as waste of energy, inaccurate data, troublesome follow-up processing, etc., and achieve the effect of reducing working time and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

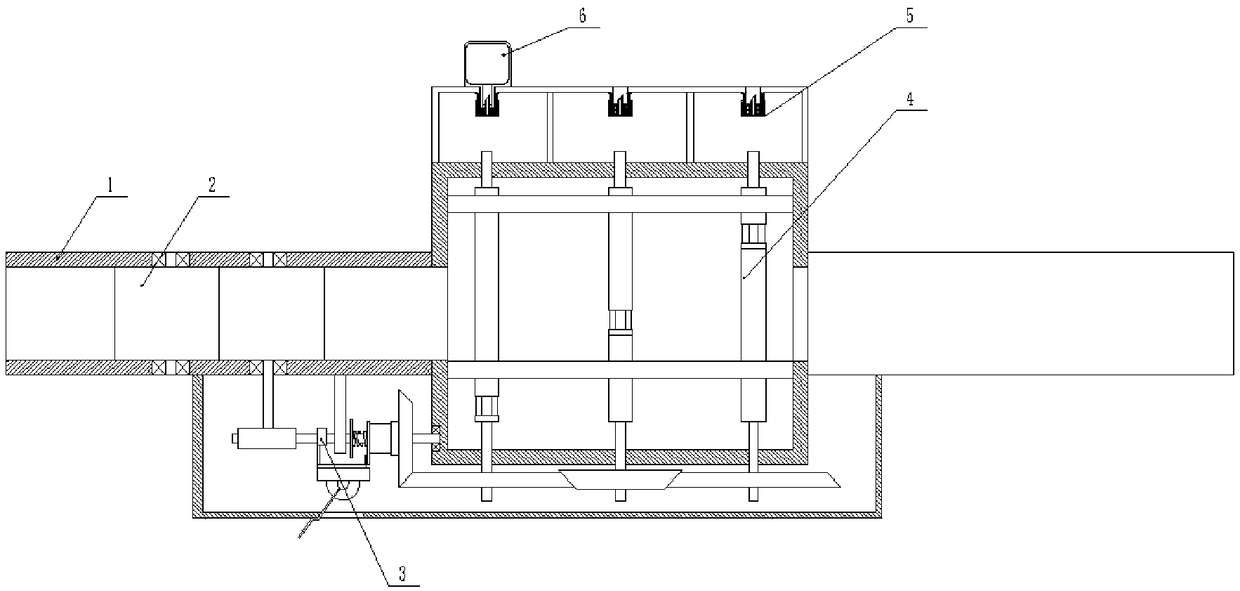

[0026] Embodiment 1: A wastewater sampling device for comprehensive utilization of wastewater in winemaking enterprises, including: winemaking wastewater centralized pipeline 1, power device 2, transmission clutch device 3, layered sampling device 4, wastewater collection connection fixture 5 and wastewater collection device 6,

[0027] The brewing wastewater centralized pipeline 1 is provided with a layered sampling device 4, the upper end of the layered sampling device 4 is provided with a waste water collecting connection fixing device 5, the waste water collecting connection fixing device 5 is provided with a waste water collecting device 6, and the layered sampling device 4 The lower part is connected to the transmission clutch device 3 arranged on the concentrated brewing wastewater pipeline 1 through a gear, and the transmission clutch device 3 is connected to the power device 2 arranged in the concentrated brewery wastewater pipeline 1 through a worm gear.

Embodiment 2

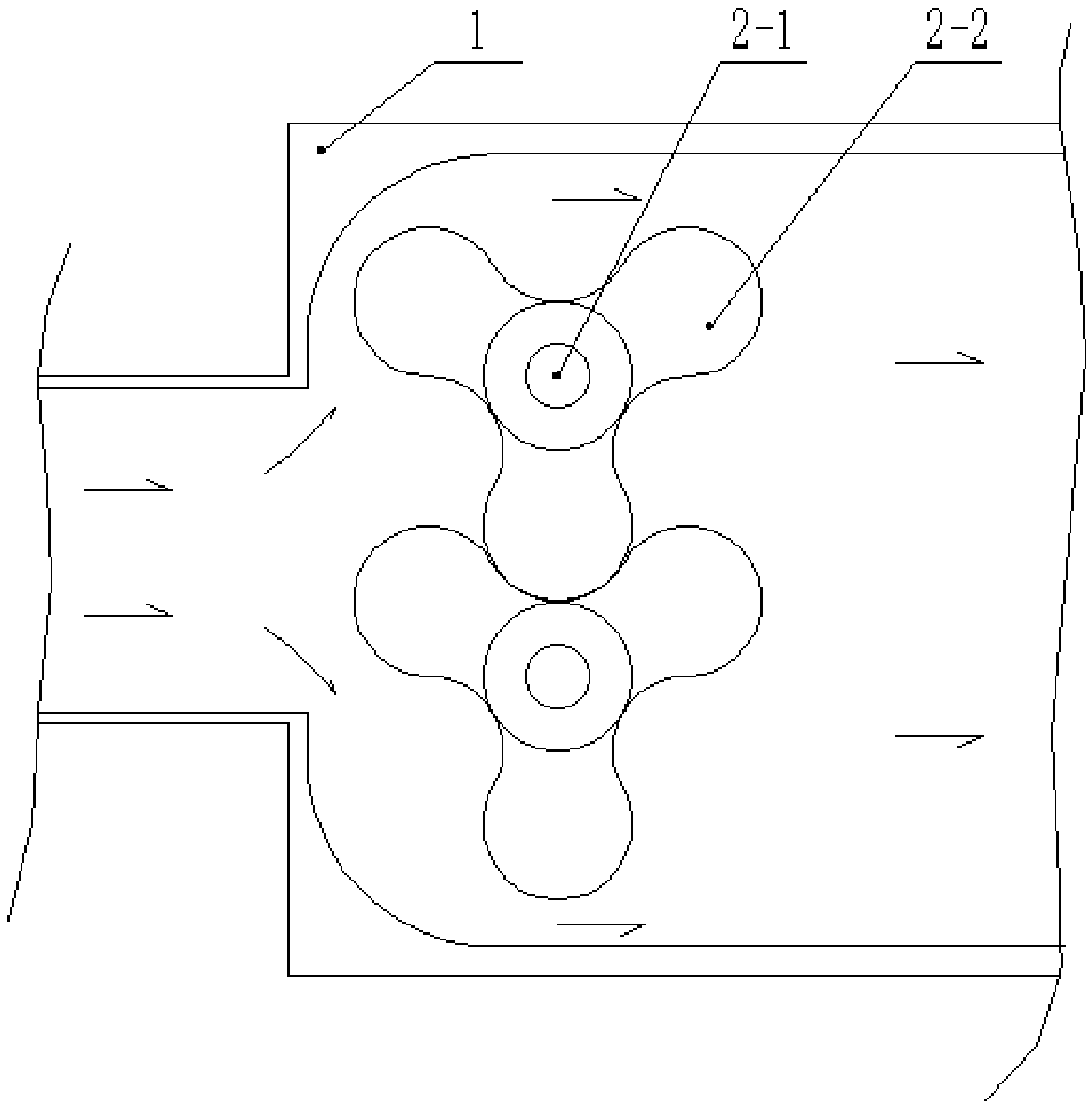

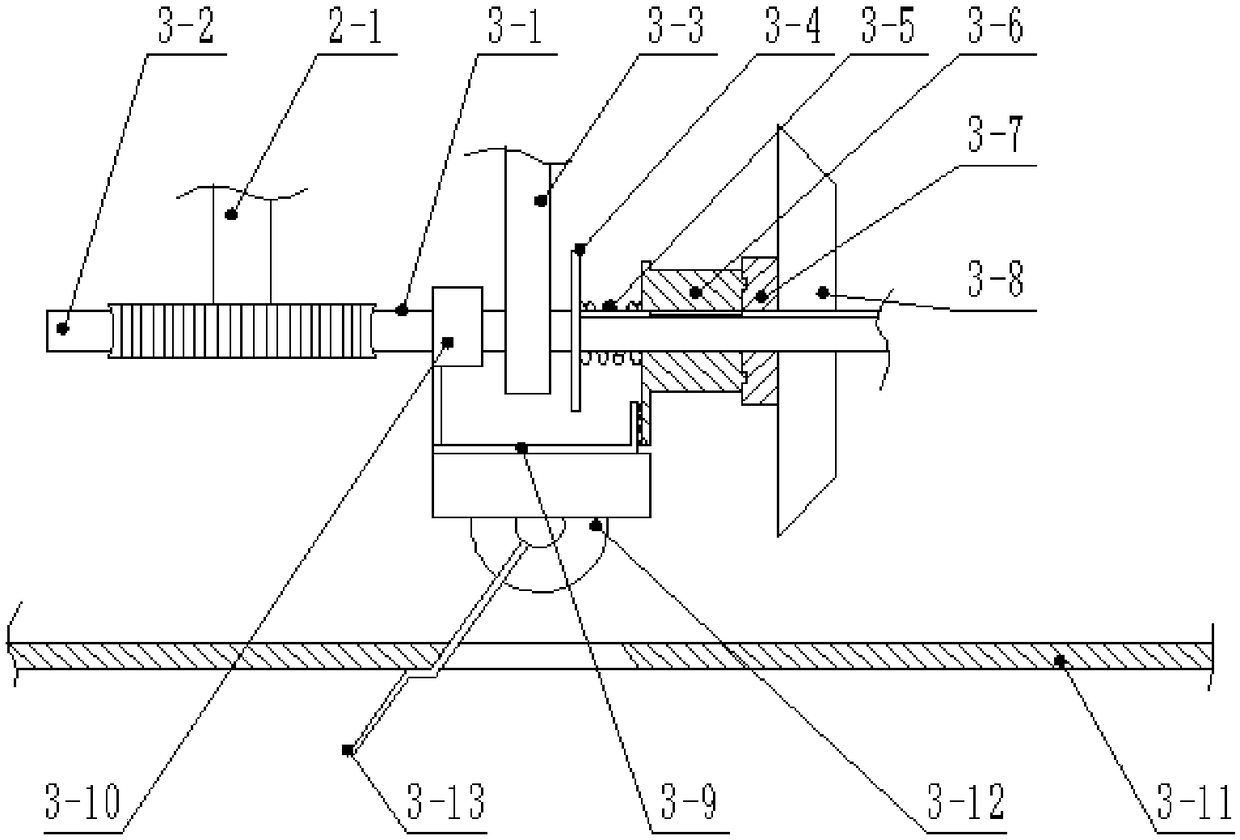

[0028] Embodiment 2: The layered sampling device 4 includes: a sampling housing 4-1, a fixed plate 4-2 and a waste water lifting device 4-3, and the left and right ends of the sampling housing 4-1 are respectively provided with waste water inlets and The wastewater outlet, the wastewater inlet and the wastewater outlet are all connected to the brewing wastewater centralized pipeline 1, and a plurality of wastewater lifting devices 4-3 are vertically arranged inside the sampling housing 4-1, and the wastewater lifting devices 4-3 pass through the fixed plate 4-2 and The internal side walls of the sampling housing 4-1 are connected, the upper end of the waste water lifting device 4-3 passes through the top of the sampling housing 4-1 and placed in the waste water collection connection fixture 5, and the lower end of the waste water lifting device 4-3 is provided with a transmission bevel gear, The adjacent waste water lifting device 4‐3 is meshed and driven by the transmission be...

Embodiment 3

[0029] Embodiment 3: The waste water lifting device 4-3 includes: a lifting housing 4-31, a screw shaft 4-32, a sampling port 4-33 and an outlet pipeline 4-34, and the side wall of the lifting housing 4-31 Sampling ports 4-33 are arranged on the top, and a screw shaft 4-32 is arranged inside the lifting housing 4-31, and the lower end of the screw shaft 4-32 passes through the bearing at the bottom of the lifting housing 4-31 and the bottom of the brewing wastewater centralized pipe 1 and The transmission bevel gears are connected, and the upper end of the lifting shell 4-31 is provided with an outlet pipeline 4-34, and the outlet pipeline 4-34 is placed in the waste water collection connection fixture 5. In this way, the sampling of each waste water lifting device 4-3 Port 4-33 is in different positions and can be sampled in layers. When the waste water lifting device 4-3 stops working, it can prevent brewing waste water from entering the waste water collection connection fixt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com