Monitoring equipment for plant area

A technology for monitoring equipment and factory areas, which is applied in the direction of mechanical equipment, supporting machines, machine tables/supports, etc. It can solve problems such as inability to adjust angles, increase factory operating investment costs, and fail to meet the needs of large factories, so as to avoid sun exposure Rain, increase the effect of monitoring range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

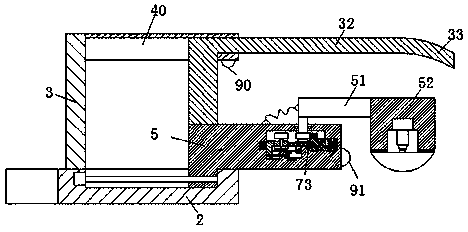

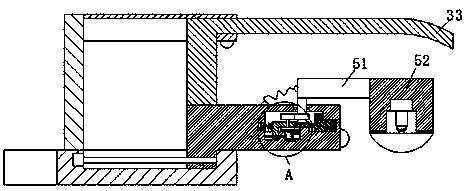

[0022] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0023] Such as Figure 1-4As shown, a monitoring device used in a factory area of the present invention includes an installation block 1 for fixed installation on a building wall and a bracket 2 fixedly connected with the installation block 1, and the top left of the bracket 2 The side is fixedly provided with a support plate 3, and the top of the right side of the support plate 3 is fixedly provided with a first cover plate 4, and the bottom surface of the first cover plate 4 is provided with a first cover plate groove 40, and the first cover plate 4 The right end is provided with a second cover plate groove 41 communicating with the first cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com