Automatic material inlet and outlet rotating-drum-type composting box

A compost bin and drum-type technology, applied in the field of feces treatment equipment, can solve the problems of incomplete solid-liquid separation, polluted environment, composting efficiency, and low degree of automation, and achieve the effects of reasonable structure, reduced environmental pollution, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

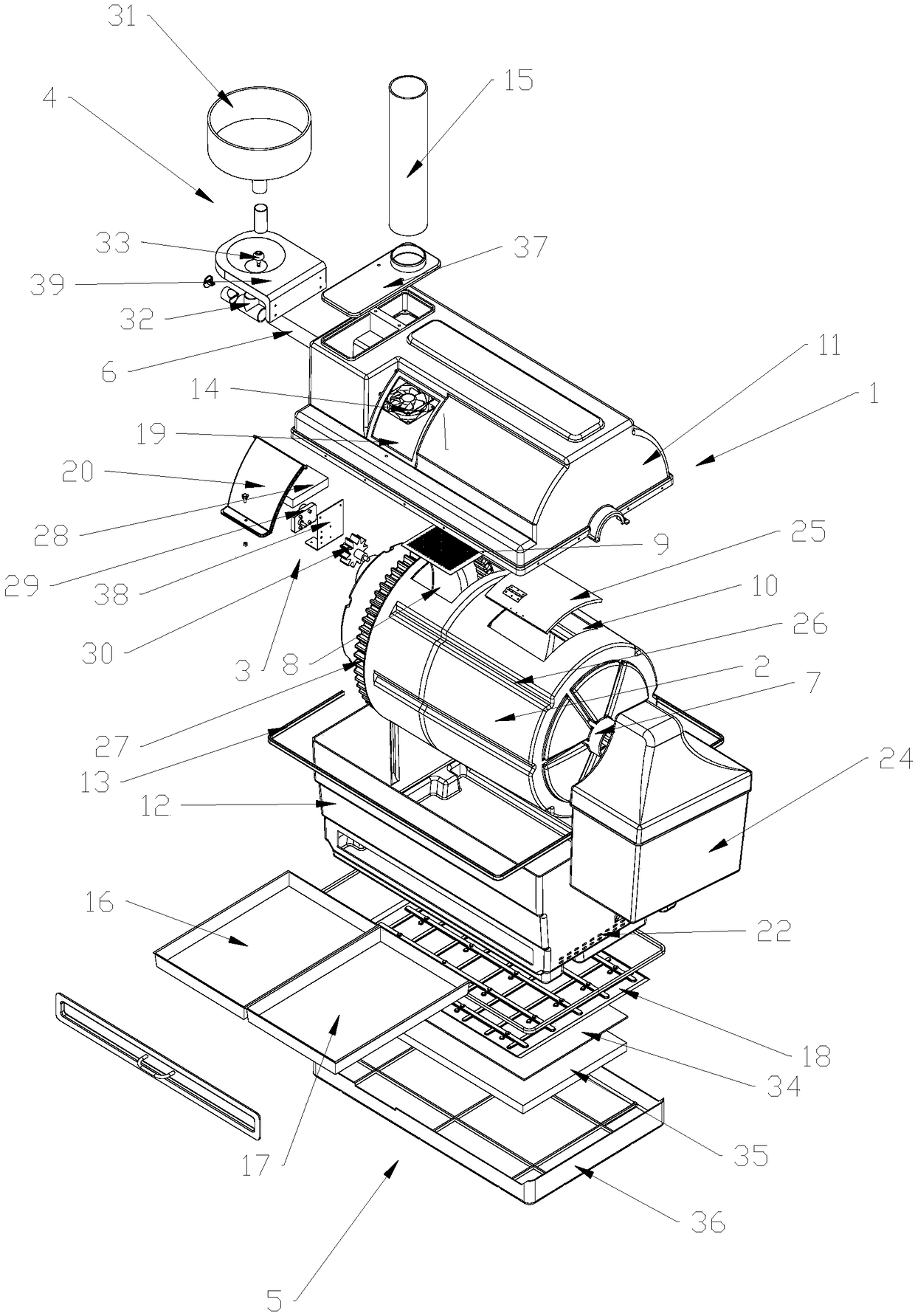

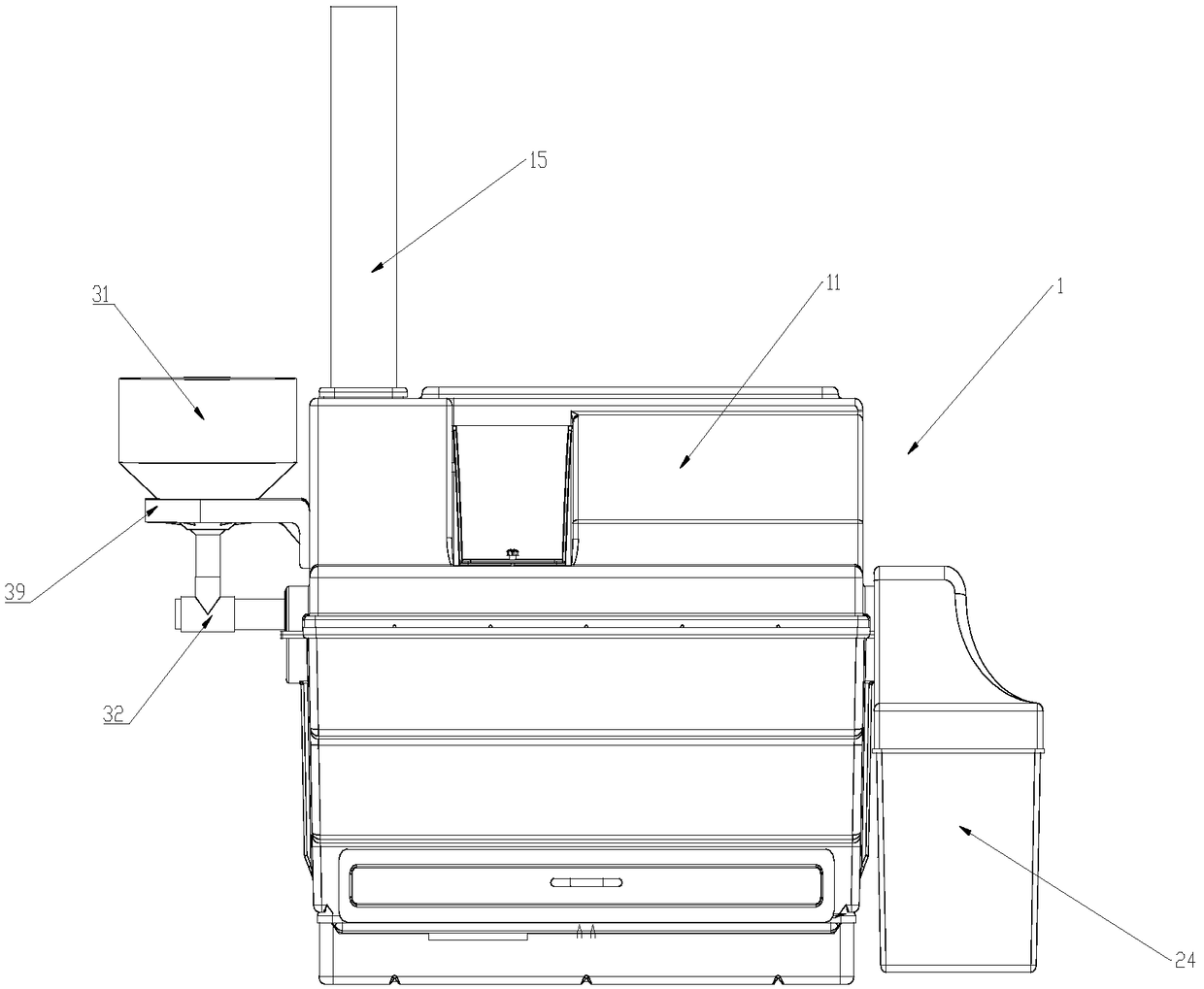

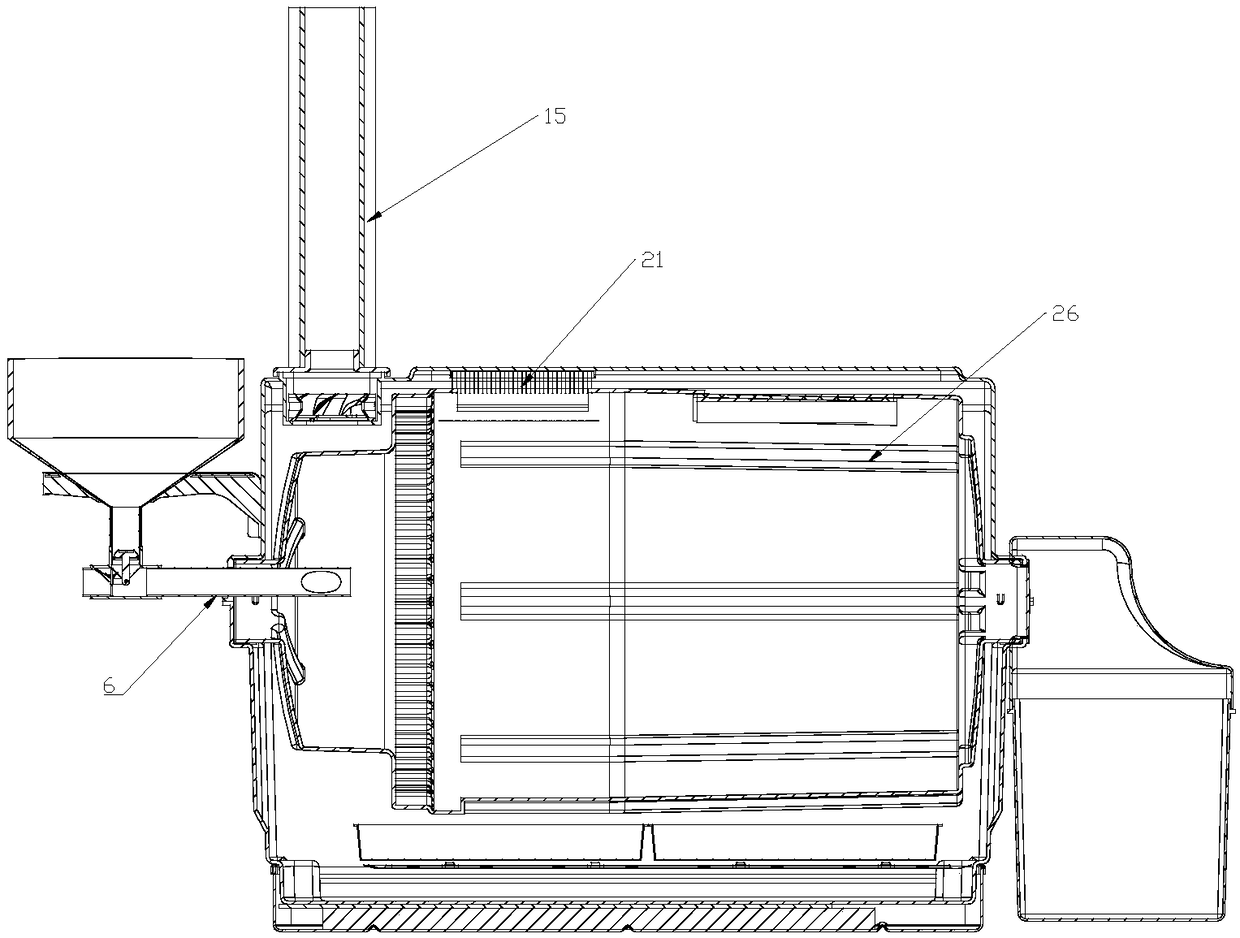

[0030] Such as figure 1 , 2 , 4, the automatic feeding and discharging drum type composting bin includes a composting bin casing 1, a drum 2, a driving device 3 and a feeding device 4.

[0031] The compost bin casing 1 includes an upper casing 11 and a lower casing 12, the upper casing 11 and the lower casing 12 are connected by bolts, and the upper casing 11 and the lower casing 12 form a detachable casing with a cavity inside. A gasket 13 is provided on the contact surface of the upper shell 11 and the lower shell 12 for sealing the gap between the upper shell 11 and the lower shell 12 .

[0032] The upper part of the upper housing 11 is provided with an air outlet channel, the air outlet channel is provided with a fan 14, the waterproof plate 37 is arranged on the top of the air outlet channel, and the waterproof plate 37 is provided with a circular hole for installing the air guide tube 15, which is convenient for the air guide tube 15 and the air outlet. The channel is ...

Embodiment 2

[0042] This embodiment is based on Embodiment 1. The difference between this embodiment and Embodiment 1 is that a cap is not provided in this embodiment, but a material storage barrel 24 is provided on one side of the compost bin casing 1, And the shaft shoulder 23 is connected with the storage bucket 24. When the drum 2 rotates in the forward direction, when the discharge port 10 rotates to the bottom, the discharge baffle 25 is in a closed state. Therefore, the amount of fertilizer in the drum 2 will continue to increase. When the pre-decomposed fertilizer accumulates beyond the shaft shoulder , can flow out from the shaft shoulder mouth, and now the pre-decomposed fertilizer is collected by the storage bucket 24.

[0043] In addition, in this embodiment, a heating device 5 is provided below the evaporating tray 18. The heating device 5 includes a temperature control switch, a heating plate 34, thermal insulation cotton 35, and a waterproof bottom plate 36 arranged in seque...

Embodiment 3

[0046] This embodiment is based on 1. The difference between this embodiment and Embodiment 1 is that a black water buffer tank is arranged on the top of the upper casing 11 in this embodiment, and the black water buffer tank is connected with the three-way pipe fitting 32, The black water pipeline is connected. When the drum 2 turns to a certain angle, the valve of the black water buffer tank opens, and the feces fall directly into the drum 2 by gravity. When the drum 2 turns to another angle, the valve of the black water buffer tank automatically When the valve is closed, the black water discharged from the toilet will be temporarily stored in the black water buffer tank to accumulate black water for the next cycle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com