Sludge treatment system

一种污泥处理、污泥的技术,应用在污泥处理、水/污泥/污水处理、脱水/干燥/浓缩污泥处理等方向,能够解决干燥效果不好、干燥效率低、结构复杂等问题,达到提高空间利用率、机构简单的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

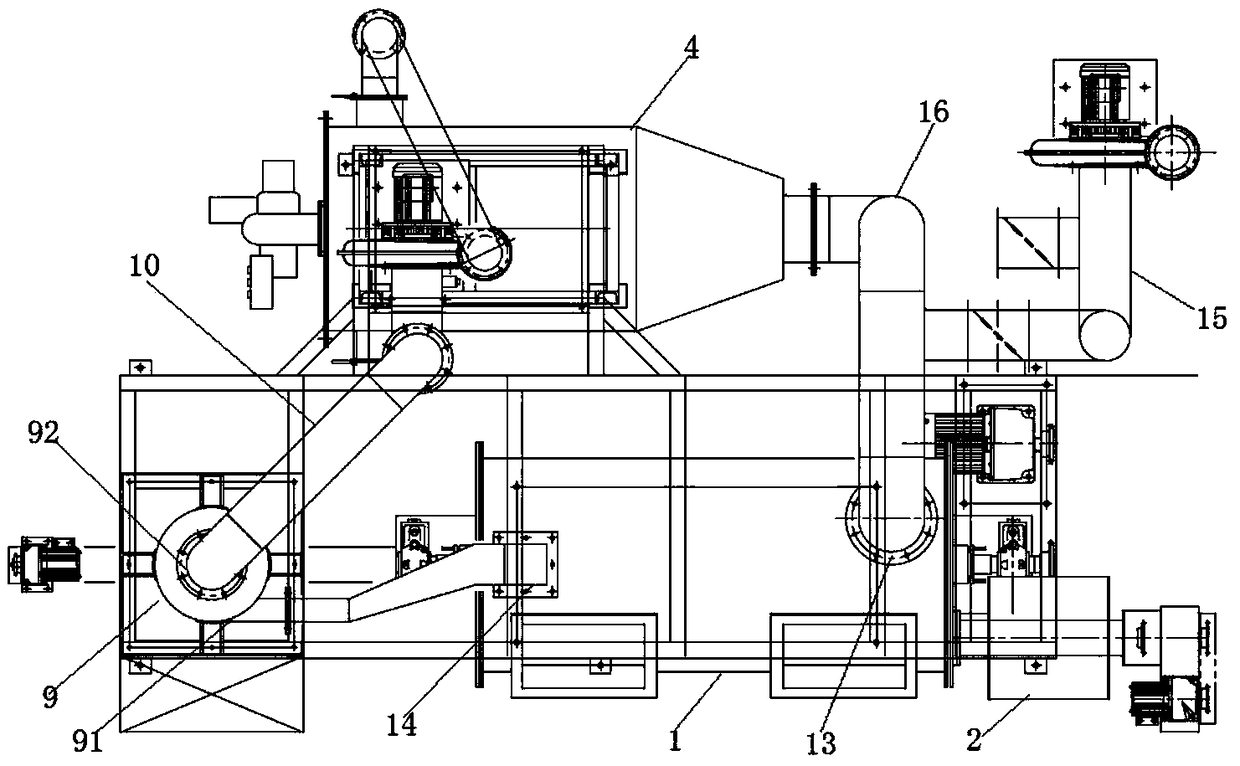

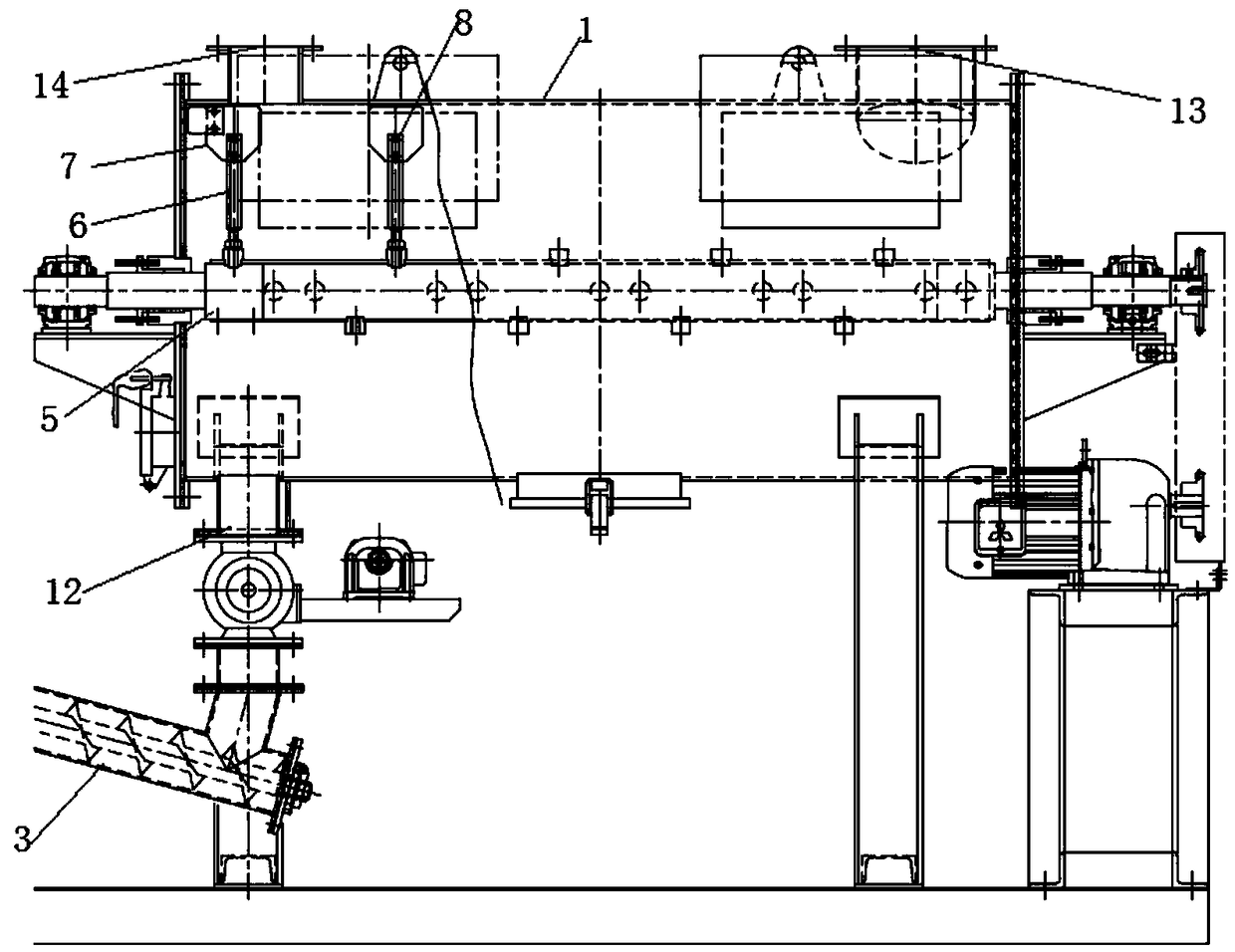

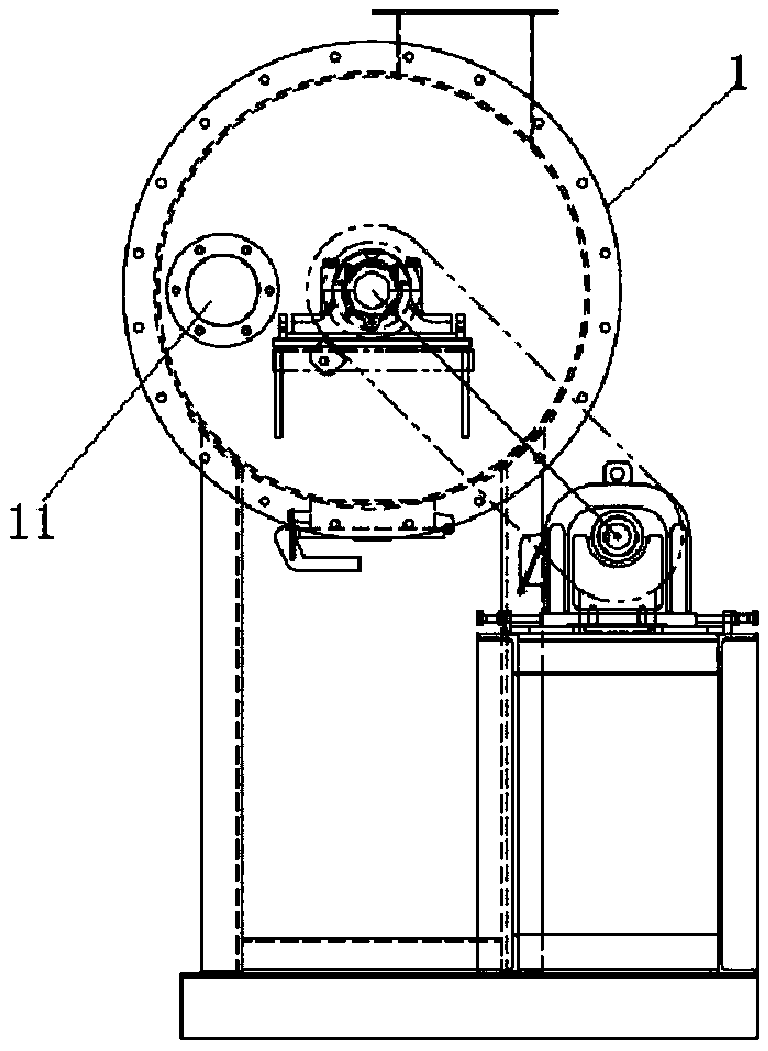

[0043] Such as Figure 5 As shown, this embodiment provides a sludge treatment system, including

[0044] The transmission device has a two-stage transmission surface, the first-stage transmission surface 200 is located above the side of the second-stage transmission surface 300, the first-stage transmission surface 200 and the second-stage transmission surface 300 are connected by a transition device 500, and the transmission The device can transport the solid-liquid mixed sludge from the head end of the first-stage transmission surface 200 to the tail end of the first-stage transmission surface 200, and introduce it to the second-stage transmission surface 300 through the transition device, and transfer it from the second stage The head end of the surface 300 is transported to the tail end of the second stage transmission surface;

[0045] The dewatering structure includes a water outlet hole 400 arranged on each conveying surface, and a pressing plate 100 on each conveying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com