Reclaimed water recycling device of reconstituted tobacco wastewater and technology thereof

A technology for reconstituting tobacco leaves and wastewater, which is applied in aerobic and anaerobic process treatment, water/sewage treatment, biological water/sewage treatment, etc. Cost, effect of improving the ability to remove COD and ammonia nitrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following is a further detailed description of the work of the present invention through the accompanying drawings and embodiments to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concept and technical solutions of the present invention.

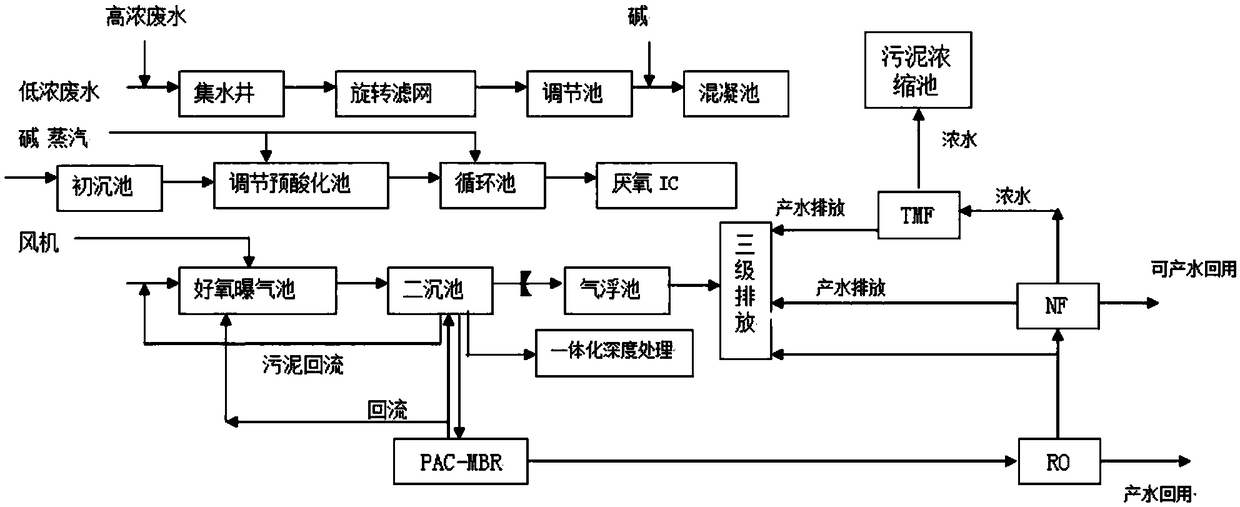

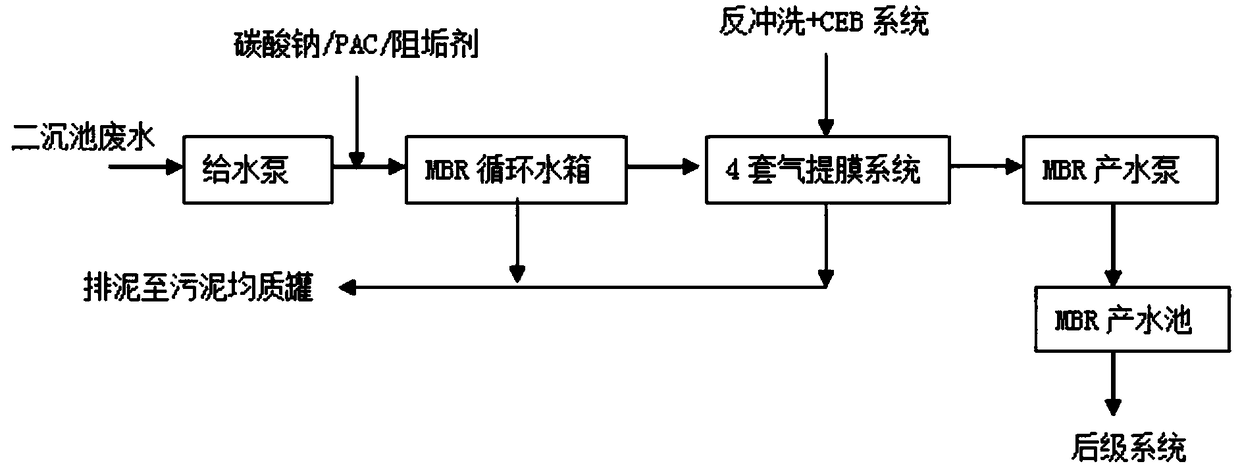

[0031] Such as Figure 1-4 As shown, the reclaimed tobacco waste water reuse device of the present invention includes a biochemical treatment system and an advanced treatment system. The biochemical treatment system includes a collection well connected by a pipeline, a rotating filter screen, a regulating tank, and a coagulation tank. , Primary sedimentation tank, adjustment pre-acidification tank, circulation tank, anaerobic tank, aerobic tank, secondary sedimentation tank; the advanced treatment system includes membrane bioreactor, reverse osmosis system, nanofiltration system and membrane chemical reactor, After the effluent from the secondary sedimentation tank of the bio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com