Encapsulation system and method

A technology of potting and potting glue, which is applied in coatings, devices for coating liquid on the surface, etc., can solve the problems of poor effect and affecting heat dissipation, and achieve the effect of improving the effect and reducing the entry of air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0032] Please refer to figure 1 , this embodiment provides a potting system 100, which is used for potting the object to be potted formed by the assembly of the main stator and the casing of the axial field motor. It includes a glue discharging device 110 and a potting and curing device 120 .

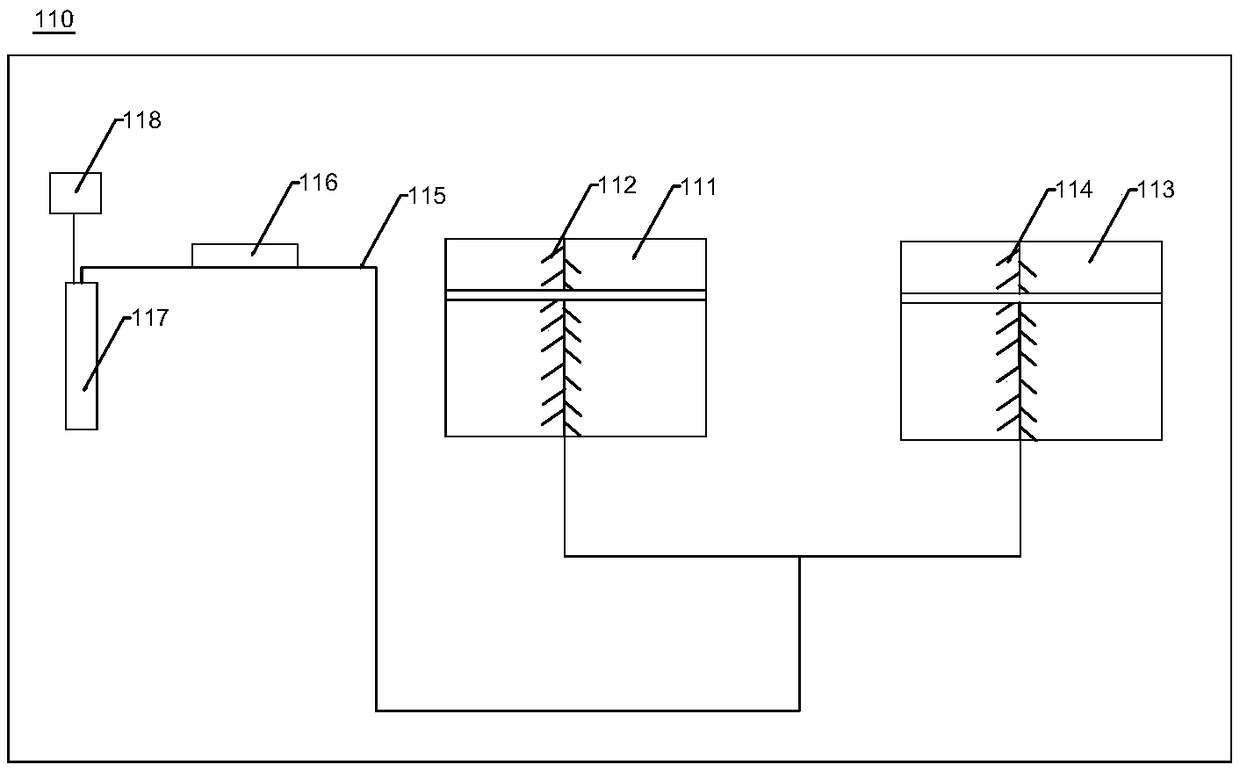

[0033] Among them, see figure 2 , the glue discharging device 110 may include: a first barrel 111 , a first stirring impeller 112 , a second barrel 113 , a second stirring impeller 114 , a pipeline 115 , a regulating valve 116 and a glue discharging head 117 .

[0034] One end of the pipeline 115 communicates with the first barrel 111 and the second barrel 113 respectively, for example communicates with the bottom of the first barrel 111 and the second barrel 113 respectively, and the other end communicates with the bottom of the first barrel 111 and the second barrel 113 respectively, The valve 116 communicates with the glue outlet head 117 .

[0035] The first stirring impeller 11...

no. 2 example

[0062] Please refer to Figure 4 , the second embodiment of the present invention provides a potting method, which is applied to the potting system 100 described in any implementation manner in the first embodiment.

[0063] The methods include:

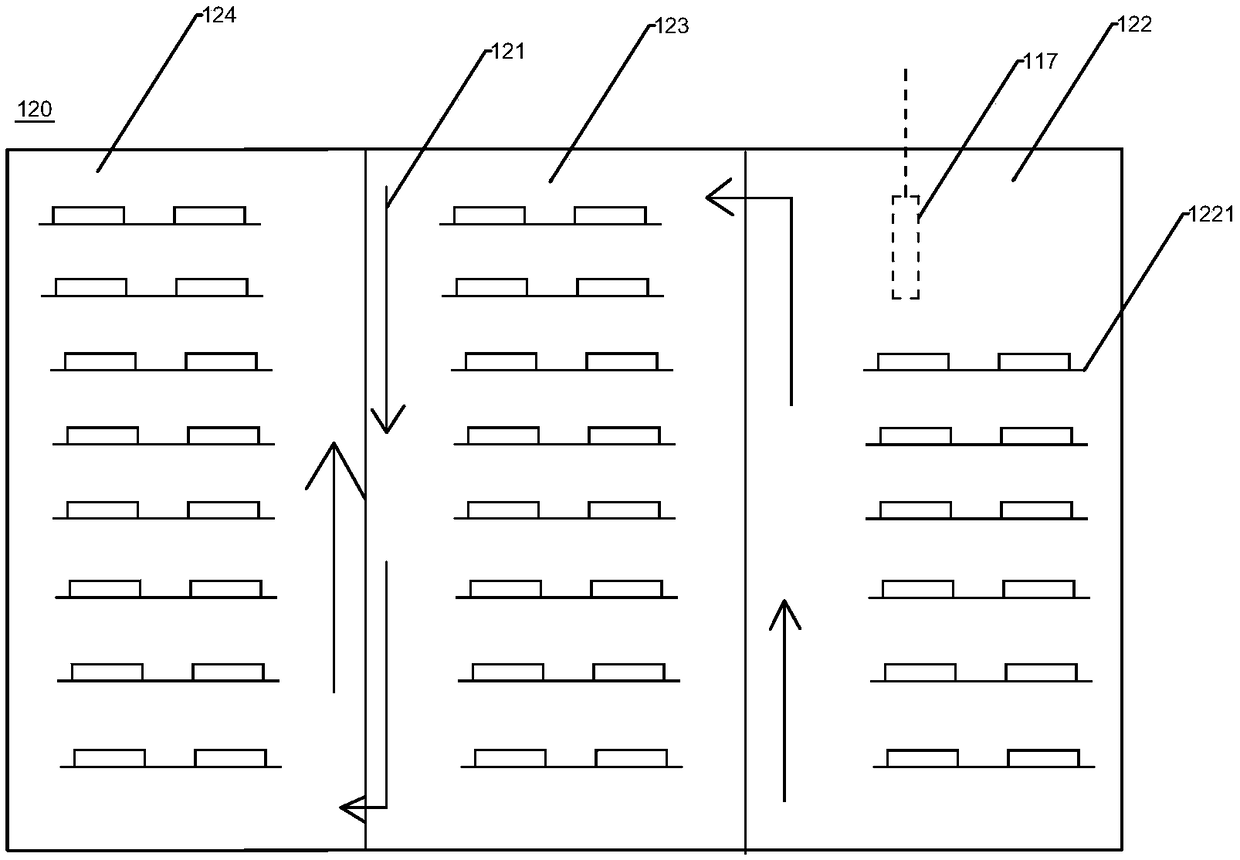

[0064] Step S110: Open the glue outlet device, so that the potting glue reaching the preset ratio starts to pot the object to be potted placed in the vacuum potting area, and at the same time pump the vacuum potting area Vacuum and heat.

[0065] Optionally, a plurality of objects to be potted are placed on the tray in the vacuum potting area, and the glue discharging device is opened, so that the potting glue that reaches a preset ratio starts to be placed in the vacuum potting area The described object to be potted in is potted, including:

[0066] Open the glue-discharging device so that the potting glue that reaches the preset ratio starts to perform multiple rounds of potting on the plurality of objects to be potted; wherein,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com