Crushing device for medical small glass garbage

A crushing device and glass technology, applied in applications, cocoa, grain processing, etc., can solve the problems of high labor intensity, glass fragments of medical staff, production accidents, etc., and achieve the effect of fine crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

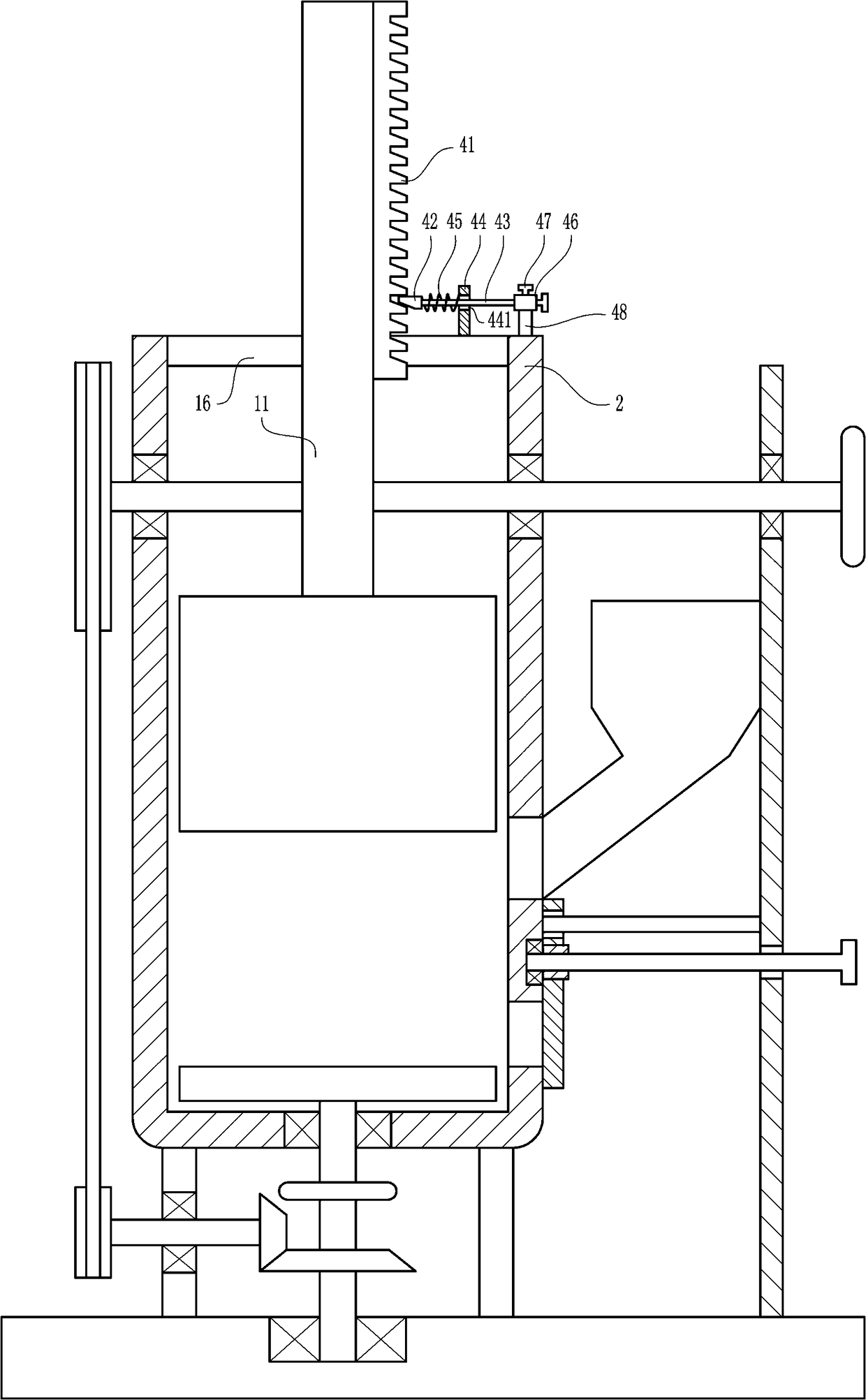

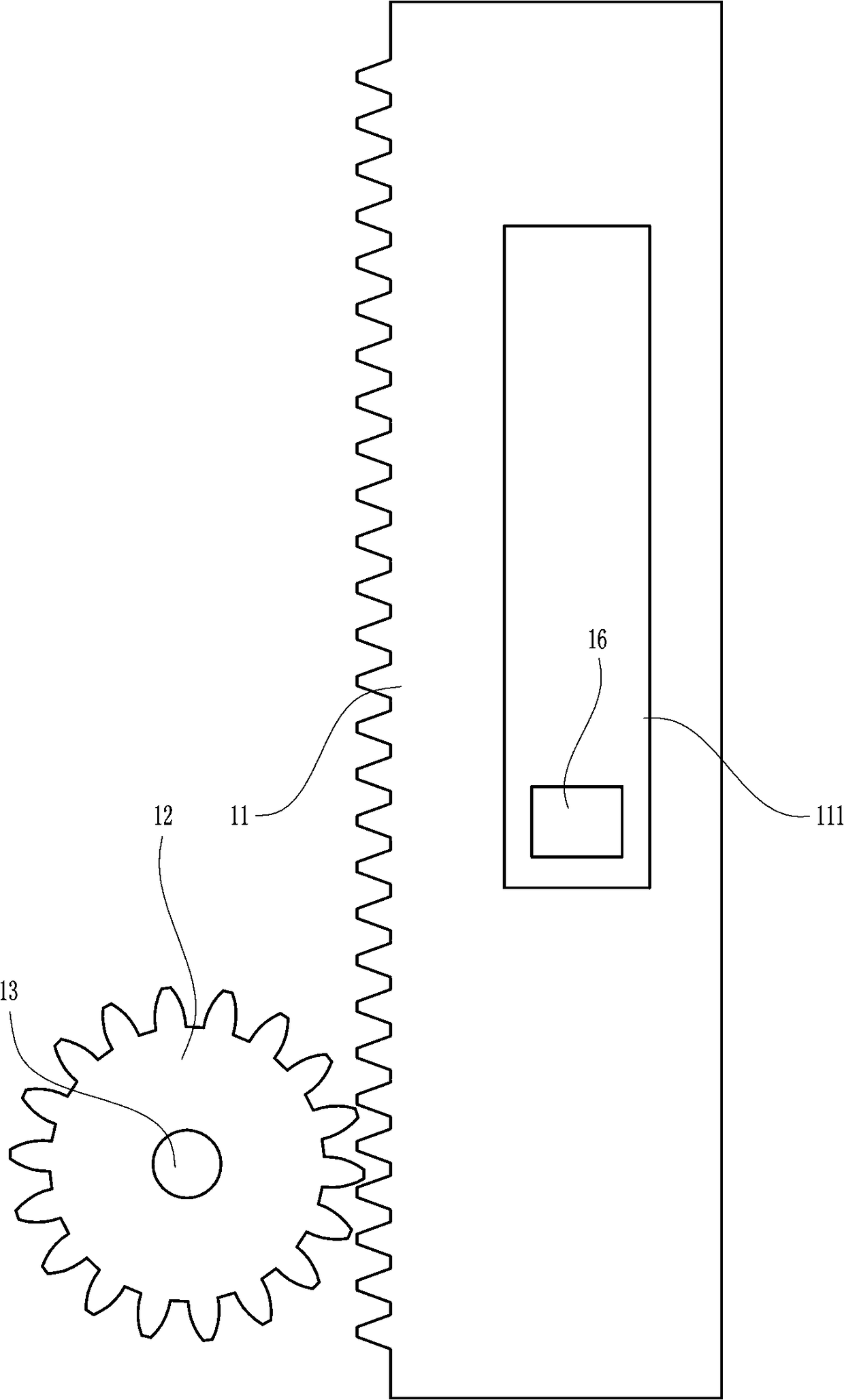

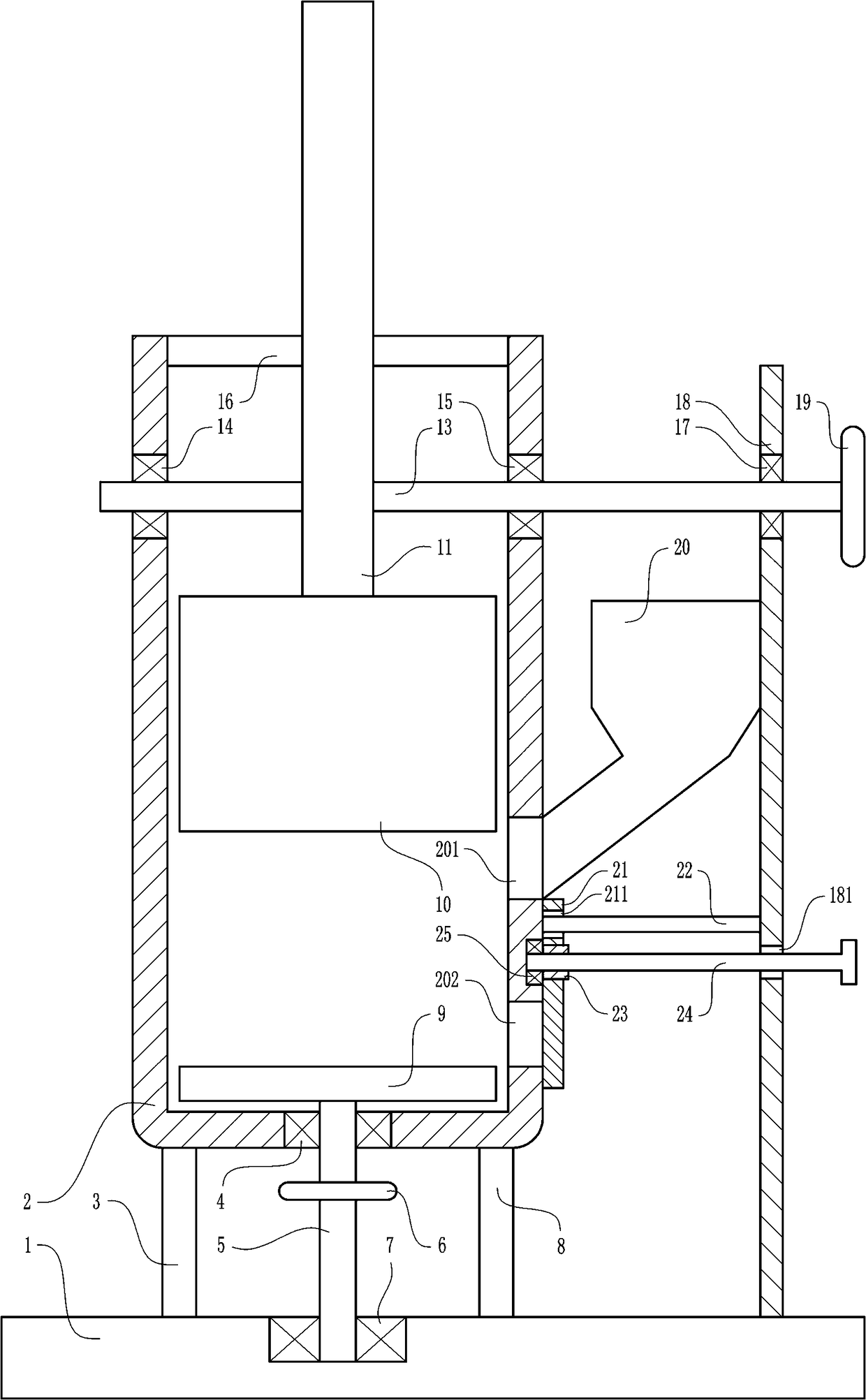

[0025] A crushing device for medical small glass waste, such as Figure 1-6 As shown, it includes base 1, crushing cylinder 2, first leg 3, first bearing 4, rotating shaft 5, first rotating wheel 6, second bearing 7, second leg 8, rotating disc 9, extrusion Column 10, gear plate 11, large gear 12, long connecting shaft 13, third bearing 14, fourth bearing 15, guide block 16, fifth bearing 17, large support plate 18, second rotating wheel 19, hopper 20, block Plate 21, guide rod 22, nut 23, large screw rod 24 and sixth bearing 25, the crushing cylinder 2 is located above the base 1, the first leg 3 is located between the crushing cylinder 2 and the base 1, the lower end of the first leg 3 It is connected to the top of the base 1, the upper end of the first leg 3 is connected to the left side of the bottom of the crushing cylinder 2, the first bearing 4 is embedded in the middle of the bottom of the crushing cylinder 2, and the upper part of the rotating shaft 5 is connected to ...

Embodiment 2

[0027] A crushing device for medical small glass waste, such as Figure 1-6 As shown, it includes base 1, crushing cylinder 2, first leg 3, first bearing 4, rotating shaft 5, first rotating wheel 6, second bearing 7, second leg 8, rotating disc 9, extrusion Column 10, gear plate 11, large gear 12, long connecting shaft 13, third bearing 14, fourth bearing 15, guide block 16, fifth bearing 17, large support plate 18, second rotating wheel 19, hopper 20, block Plate 21, guide rod 22, nut 23, large screw rod 24 and sixth bearing 25, the crushing cylinder 2 is located above the base 1, the first leg 3 is located between the crushing cylinder 2 and the base 1, the lower end of the first leg 3 It is connected to the top of the base 1, the upper end of the first leg 3 is connected to the left side of the bottom of the crushing cylinder 2, the first bearing 4 is embedded in the middle of the bottom of the crushing cylinder 2, and the upper part of the rotating shaft 5 is connected to ...

Embodiment 3

[0030] A crushing device for medical small glass waste, such as Figure 1-6As shown, it includes base 1, crushing cylinder 2, first leg 3, first bearing 4, rotating shaft 5, first rotating wheel 6, second bearing 7, second leg 8, rotating disc 9, extrusion Column 10, gear plate 11, large gear 12, long connecting shaft 13, third bearing 14, fourth bearing 15, guide block 16, fifth bearing 17, large support plate 18, second rotating wheel 19, hopper 20, block Plate 21, guide rod 22, nut 23, large screw rod 24 and sixth bearing 25, the crushing cylinder 2 is located above the base 1, the first leg 3 is located between the crushing cylinder 2 and the base 1, the lower end of the first leg 3 It is connected to the top of the base 1, the upper end of the first leg 3 is connected to the left side of the bottom of the crushing cylinder 2, the first bearing 4 is embedded in the middle of the bottom of the crushing cylinder 2, and the upper part of the rotating shaft 5 is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com