Material receiving 8-shape-winding device and lala ball automatic assembly system

A component and figure-of-eight wheel technology, which is applied in the field of material receiving and winding device and cheerball automatic assembly system, can solve the problems of slow manual production of cheerleading balls, inability to self-feed and wind ribbons, etc., to speed up the total production Quantity, speed up assembly, and speed up production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The specific implementation of this embodiment is as follows:

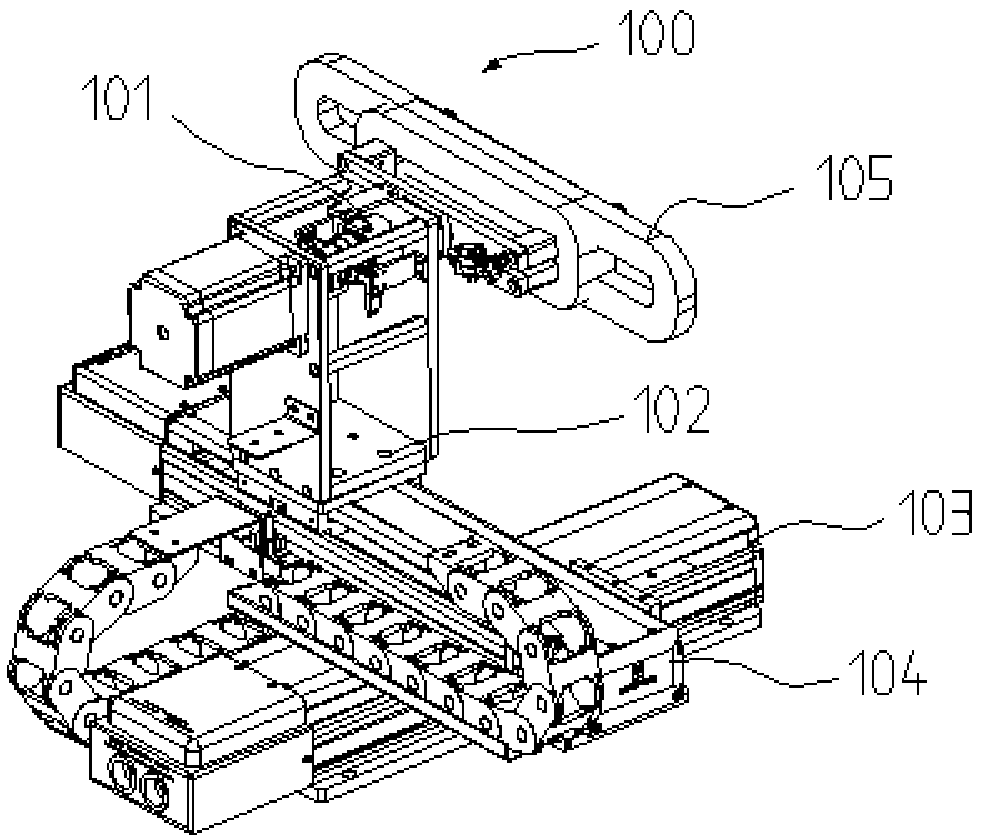

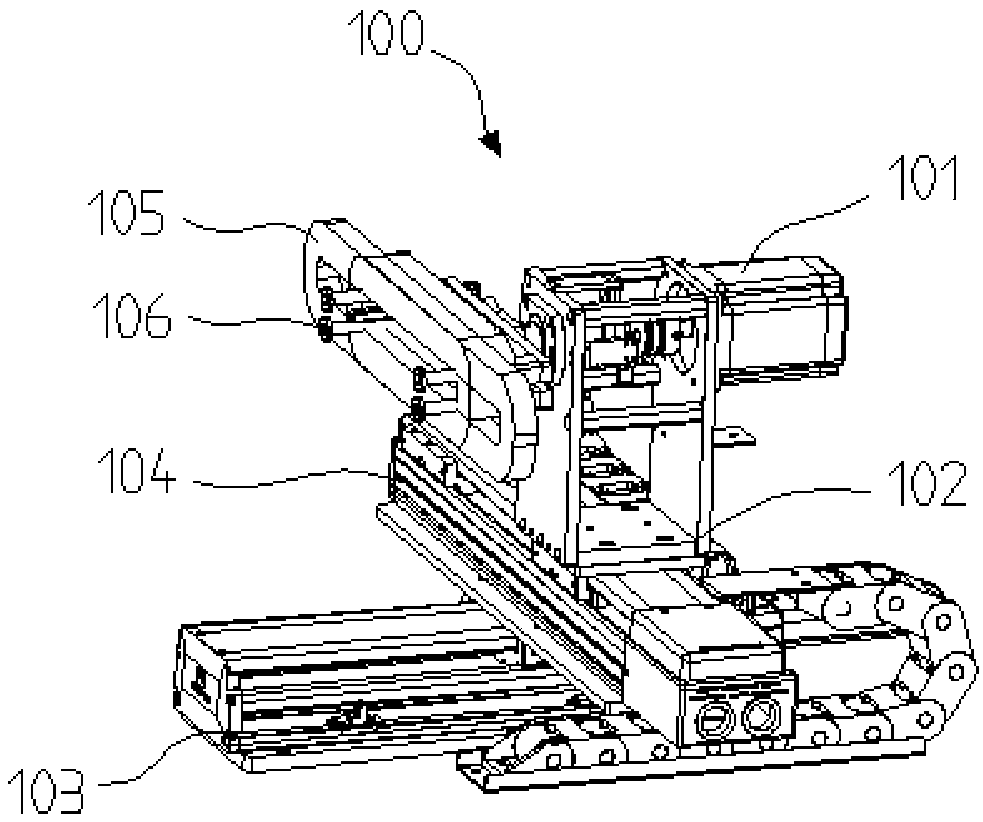

[0037] Such as figure 1 - figure 2 As shown, it is a schematic diagram of the corresponding structure of the material receiving and winding figure 8 device 100 provided in this embodiment; specifically, the material receiving and winding figure 8 device 100 provided in this embodiment includes a controller, a figure 8 winding component, and is used to support the winding 8 The bracket 102 of the word component and the linear guide rail for driving the bracket 102 to reciprocate along the X direction and the Y direction respectively; the figure 8 component is used to accept the ribbon 105; the figure 8 component is provided in pairs for winding the ribbon 105. 106; The figure-of-eight assembly is provided with figure-eight wheels 106 for winding the ribbon 105 in pairs, and the figure-eight assembly can drive the figure-eight wheel 106 to rotate the winding angle; the controller is respectively connected t...

Embodiment 2

[0057] This embodiment provides an automatic cheerball assembly system to solve the technical problems in the prior art that the manual production of cheerballs is slow and the ribbon 105 cannot be automatically wound.

[0058] An automatic cheer ball assembly system provided in this embodiment is provided with the above-mentioned material receiving and winding device 100; the ribbon 105 is moved and loaded from the previous process, and the pressure head is extended for material receiving.

[0059] The cheerball automatic assembly system of this embodiment is provided with the material receiving and winding figure-eight device 100 of the above-mentioned embodiment 1, which can provide the automatic assembly device for cheerleading balls with the process of automatically winding 105 bundles of ribbons, and speed up the process of cheerleading balls Assembling, speeding up the production efficiency of cheerleading balls and speeding up the total production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com