Automatic producing equipment for fish-shaped oat noodles

A kind of production equipment and noodle technology, which is applied in dough forming machinery or equipment, dough extruder, baking, etc. It can solve the problems of low production efficiency and poor product shape quality, and achieve high production efficiency and soft and smooth food It has the effect of toughness and automatic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be clearly and completely described below through embodiments in conjunction with the accompanying drawings.

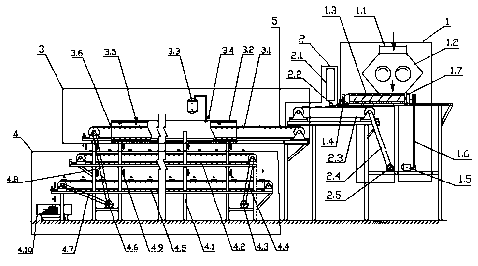

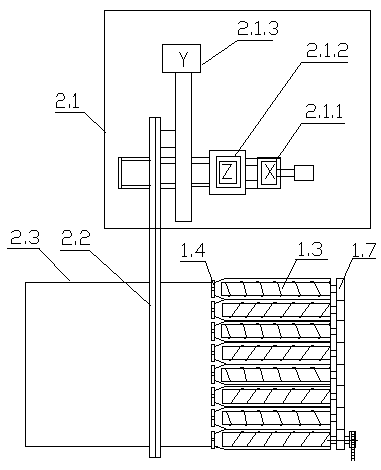

[0030] Such as figure 1 , 2 As shown in , 3 and 4, an automatic production equipment for oat noodles and fish is composed of a double-roller hopper screw extruder 1, a three-dimensional slider module fish rubbing machine 2, a noodle steaming device 3 and a cooling device 4;

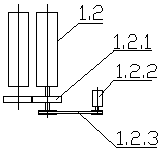

[0031] The double-roller hopper screw extruder 1 comprises: a hopper 1.1, a roll 1.2, a screw 1.3, a mold 1.4, a screw motor 1.5, a chain 1.6, a gear set 1.7, a pair of rolls 1.2, two rolls are installed in the hopper 1.1 A pair of meshing gears 1.2.1 are installed on the shaft, one gear is driven by the motor 1.2.2 of the roll through the roll transmission belt 1.2.3, and the screw 1.3 is installed horizontally at the opening below the hopper 1.1, and 8 screws 1.3 are arranged in parallel, each screw The gear set 1.7 meshing with eac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Outer width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com