Meat block tumbling device for meat processing

A meat processing and meat block technology, which is applied in the direction of meat processing, application, meat tenderization, etc., can solve the problems of limited use, fixed structure, and inability to adjust the thickness of meat, so as to improve work efficiency and increase The effect of rolling pressure and reducing processing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

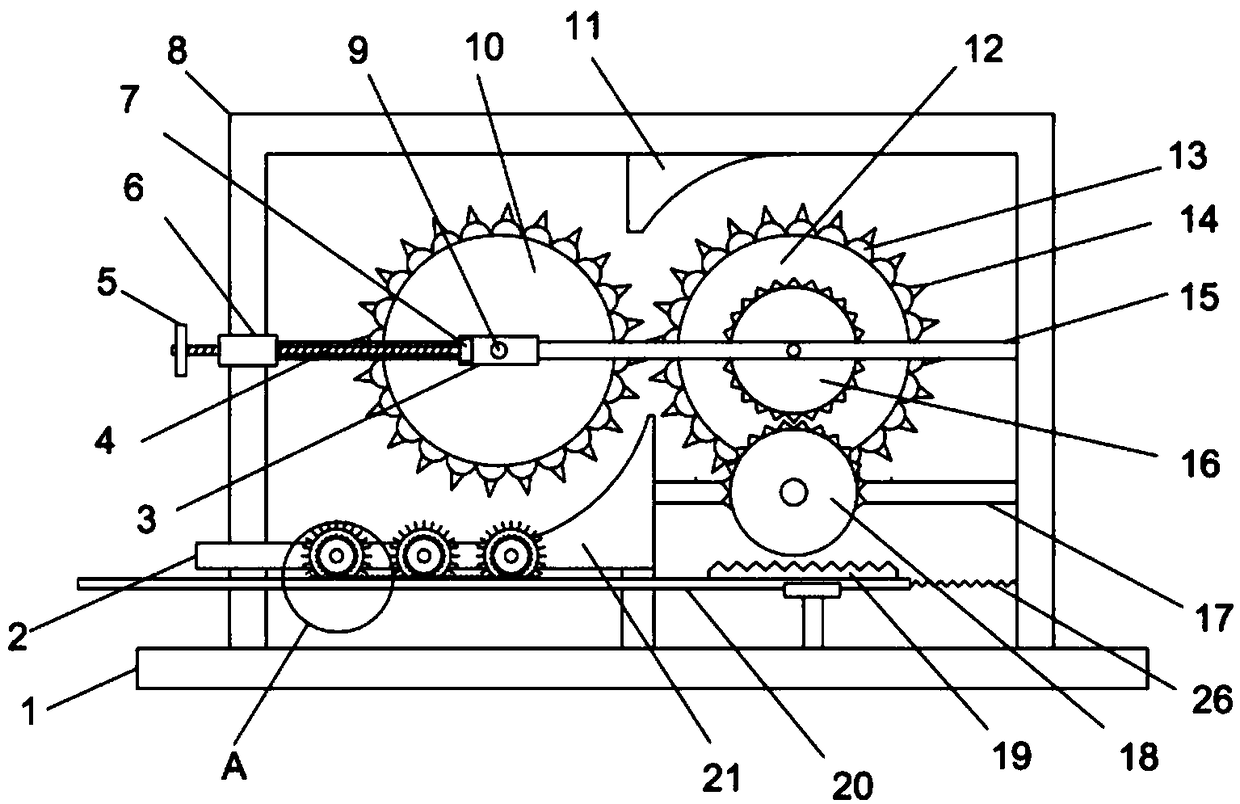

[0021] Below in conjunction with specific embodiment, the technical scheme of this patent is described in further detail:

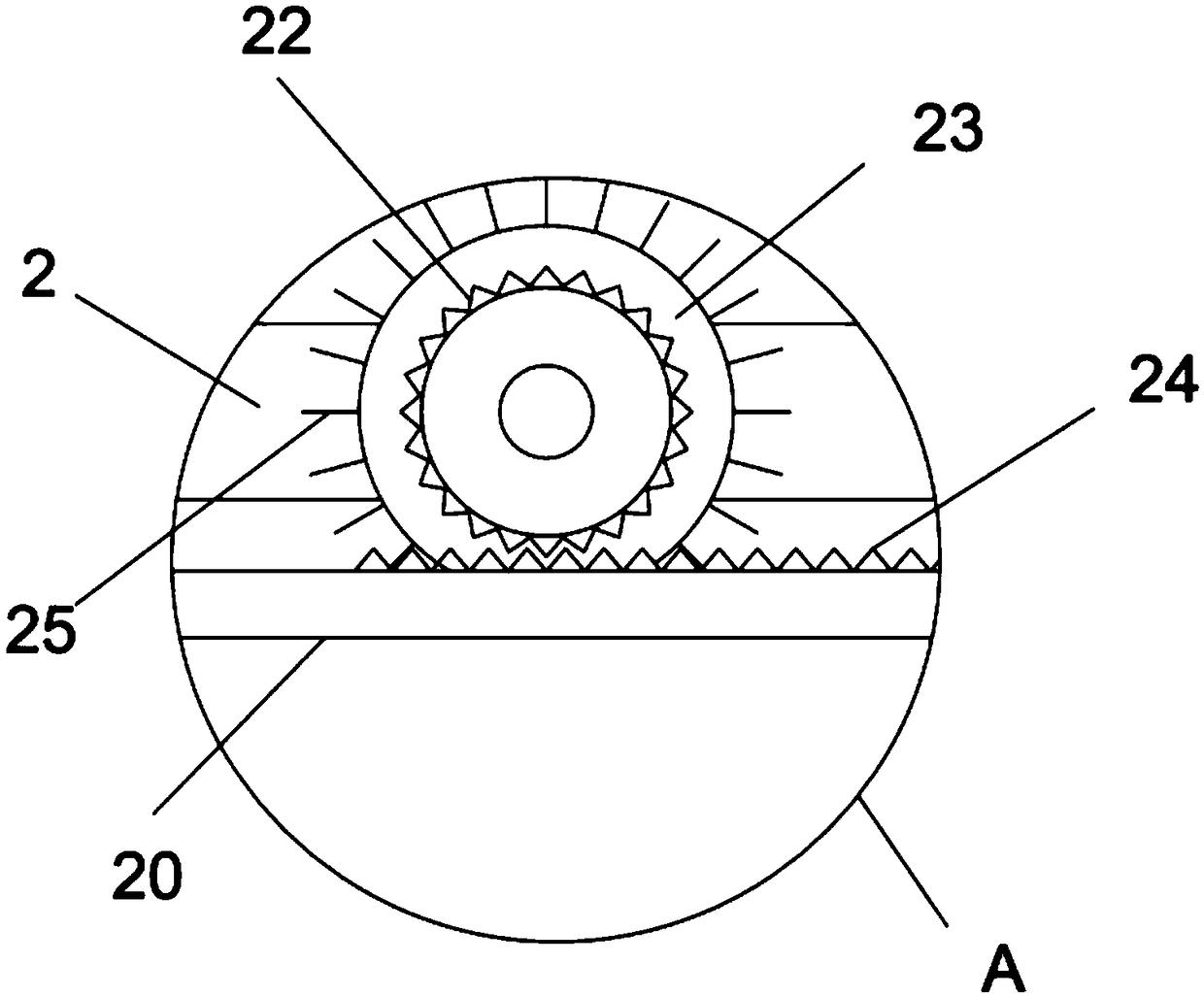

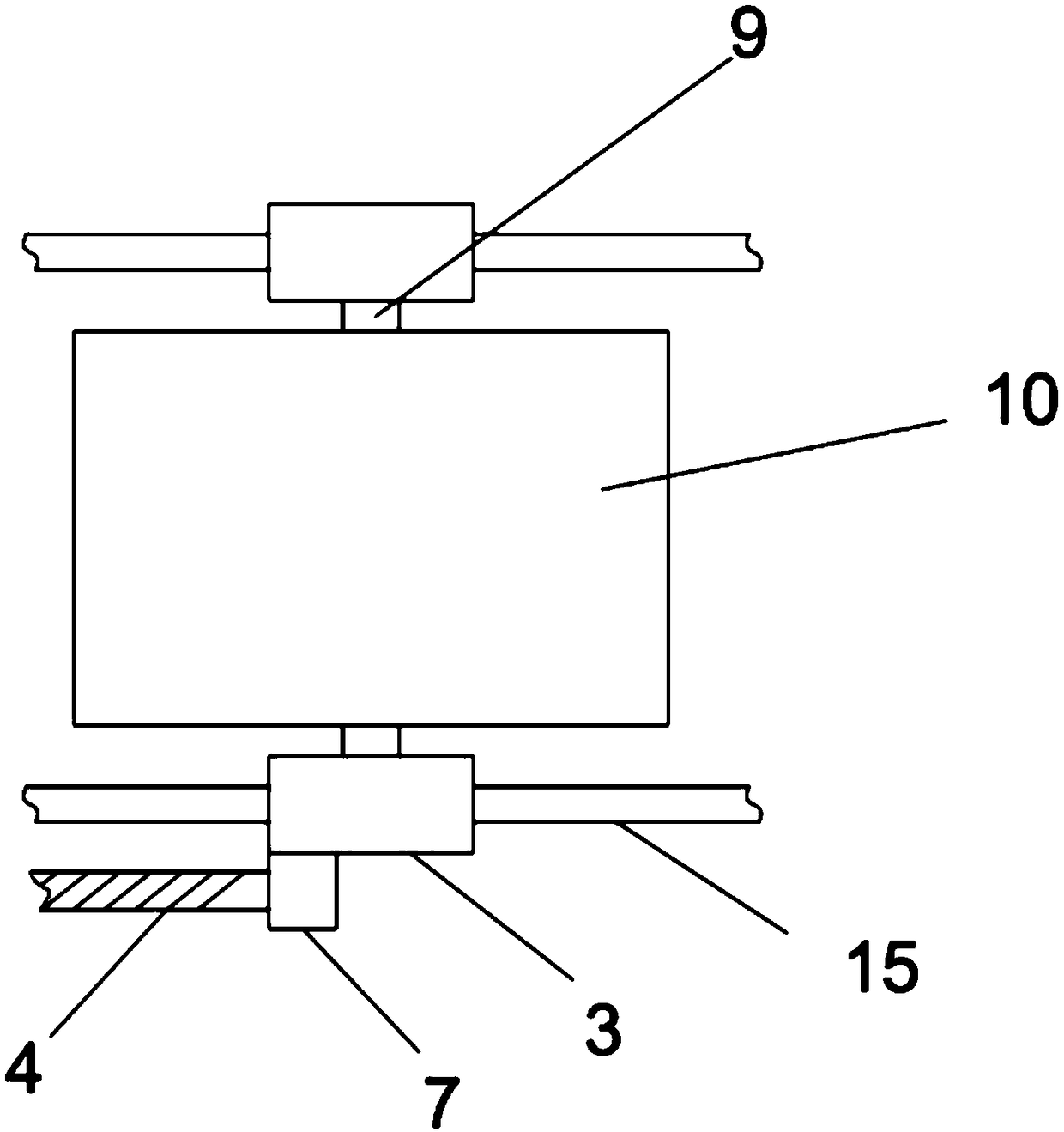

[0022] see Figure 1-3 , a meat rolling and kneading device for meat processing, comprising a load-bearing base plate 1, a support frame 8 is fixedly installed on the load-bearing base plate 1, two horizontal guide rods 15 are horizontally fixedly installed on the support frame 8, and the horizontal guide rod 15 Rotary shaft 9 is provided between them, the surface of rotating shaft 9 is sleeved and fixedly installed with auxiliary pressure roller 10, the horizontal guide rod 15 is slidably provided with sleeve block 3, and the sleeve block 3 is fixedly installed with connecting Block 7, a threaded sleeve 6 is horizontally fixed on the support frame 8, and the threaded sleeve 6 is internally threaded with a threaded rod 4 whose right end is pivotally connected to the connection block 7 through a bearing; the support frame 8 is horizontally fixed and instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com