Method for prolonging service life of motor

A technology of life and motor shaft, applied in the direction of electromechanical devices, electrical components, mechanical equipment, etc., can solve the problems of poor heat dissipation at the center of the motor shaft, shortening the service life of the motor, time-consuming and laborious motor maintenance, etc., to reduce resistance and improve use. Efficiency and easy installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

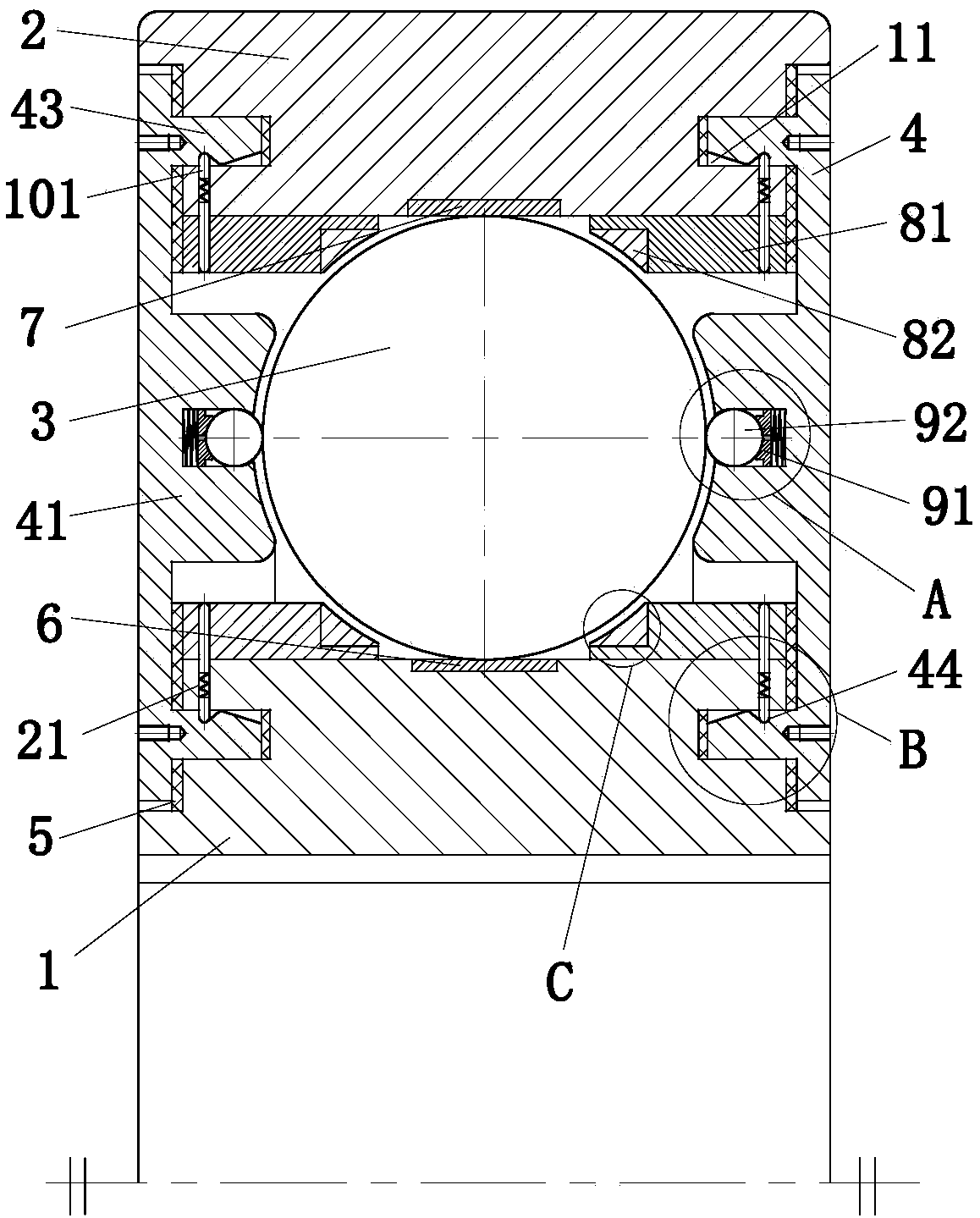

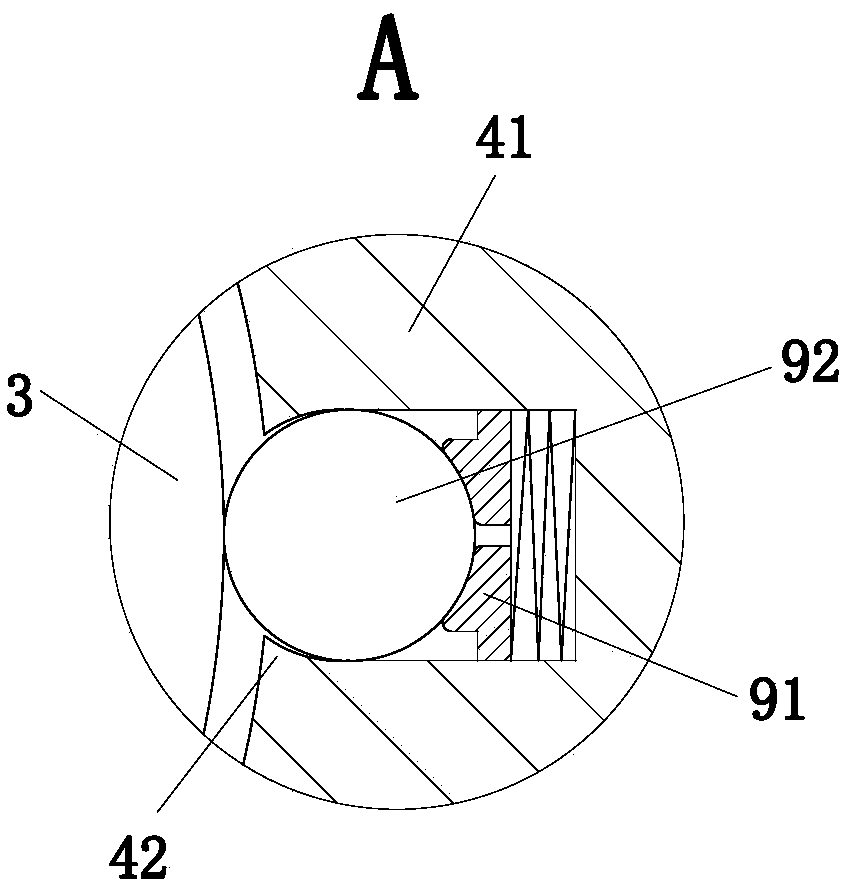

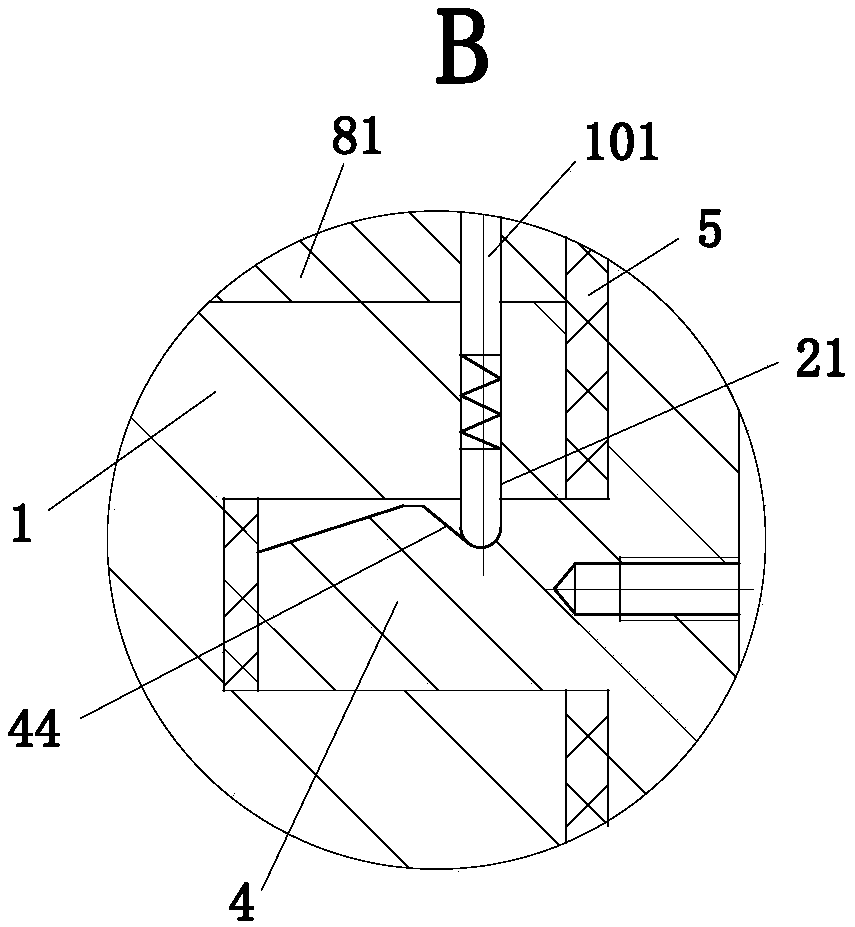

[0021] use Figure 1-Figure 4 The structure of the bearing of the present invention will be explained as follows.

[0022] Such as figure 1 Shown, a kind of method of improving motor service life described in the present invention, this method comprises the following steps:

[0023] S1, the motor shaft is connected to the motor casing through a sealed bearing;

[0024] S2, on the basis of S1, an axial through hole is provided on the motor shaft along the axial coaxial direction, a radial through hole connected with the axial through hole is provided along the radial direction of the motor shaft, the axial through hole and the radial through hole The holes can dissipate the heat inside the motor;

[0025] The sealed bearing adopted in the above method includes an inner ring 1, an outer ring 2, a ball 3 and a sealing end cap 4; A chute 21 is provided, and the chute 21 of the outer ring 2 communicates with the annular groove 11 of the outer ring 2; the inner ring 1 is also pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com