Working face mining rock stratum damage underground top and bottom plate drilling electric method monitoring method

A working face, roof and floor technology, which is applied in the field of coal seam exploration, can solve the problems of poor electrical data quality, cable breakage, and the monitoring system cannot monitor for a long time, and achieves the effect of improving reliability and increasing the space range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

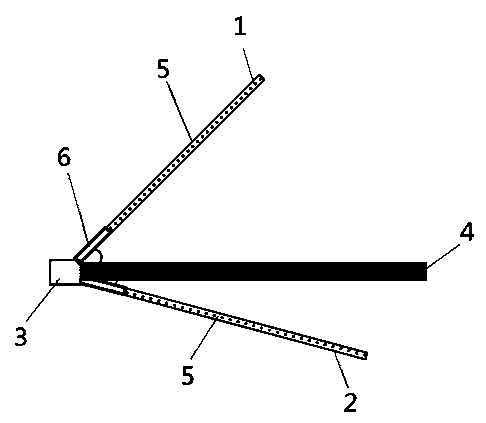

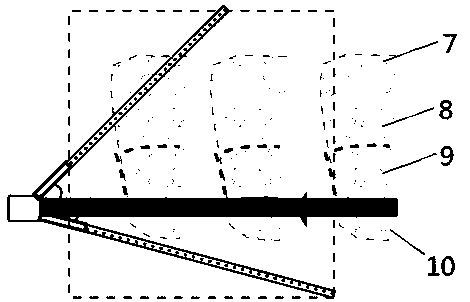

[0035] like figure 1 , figure 2 as shown, figure 1 Including 1# hole 1, 2# hole 2, roadway 3, coal seam 4, cable 5, casing 6, figure 2 Including bending subsidence zone 7, crack zone 8, collapse zone 9, floor failure zone 10. Figure 5 The dotted box in the middle is the control range of the electrical method, and the arrow points to the mining direction of the working face.

[0036] Roof and floor monitoring specifically includes the following steps:

[0037] 1. Drilling control height design: According to the geological conditions of the coal mining face, and in accordance with the 2015 energy industry standard of the People's Republic of China "Measurement Method for Dynamic Apparent Resistivity of Coal Mining Overlying Rock Destruction", calculate the height of the expected collapse zone and crack zone, Obtain the control height of borehole 1 in design 1#.

[0038] 2. Selection of drilling location: Select a suitable drilling construction location 300m in front of t...

Embodiment 2

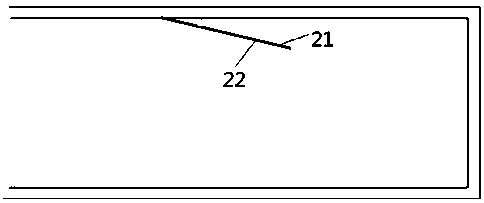

[0046] This embodiment is the roof monitoring method in the prior art. like image 3 , Figure 4 , Figure 5 As shown, the figure includes 1# hole 21 and 2# hole 22.

[0047] Subsurface formations with different lithologies usually have different characteristics of resistivity values. The drilling electrical monitoring range can be arranged at a certain position in the upper roadway or the lower roadway on the coal mining face to monitor the change of resistivity value. The plane projection position of the drilling end point should be more than 100m away from the coal cutting position. The current electrical monitoring method for overlying rock damage in underground boreholes is to arrange a pair of boreholes on the roof. The two boreholes coincide or can be regarded as coincident on the plane, and have different borehole elevation angles on the vertical surface. floor plan as image 3 As shown, the vertical section is arranged as Figure 4shown. The height of the final...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com