Sand particle gradient fatigue liquefaction experiment device and method

A particle gradient and experimental device technology, applied in the direction of analyzing materials, instruments, etc., can solve the problems of inability to simulate the phenomenon of sand and soil particle gradient fatigue liquefaction, latent corrosion of composite slopes, and landslide instability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

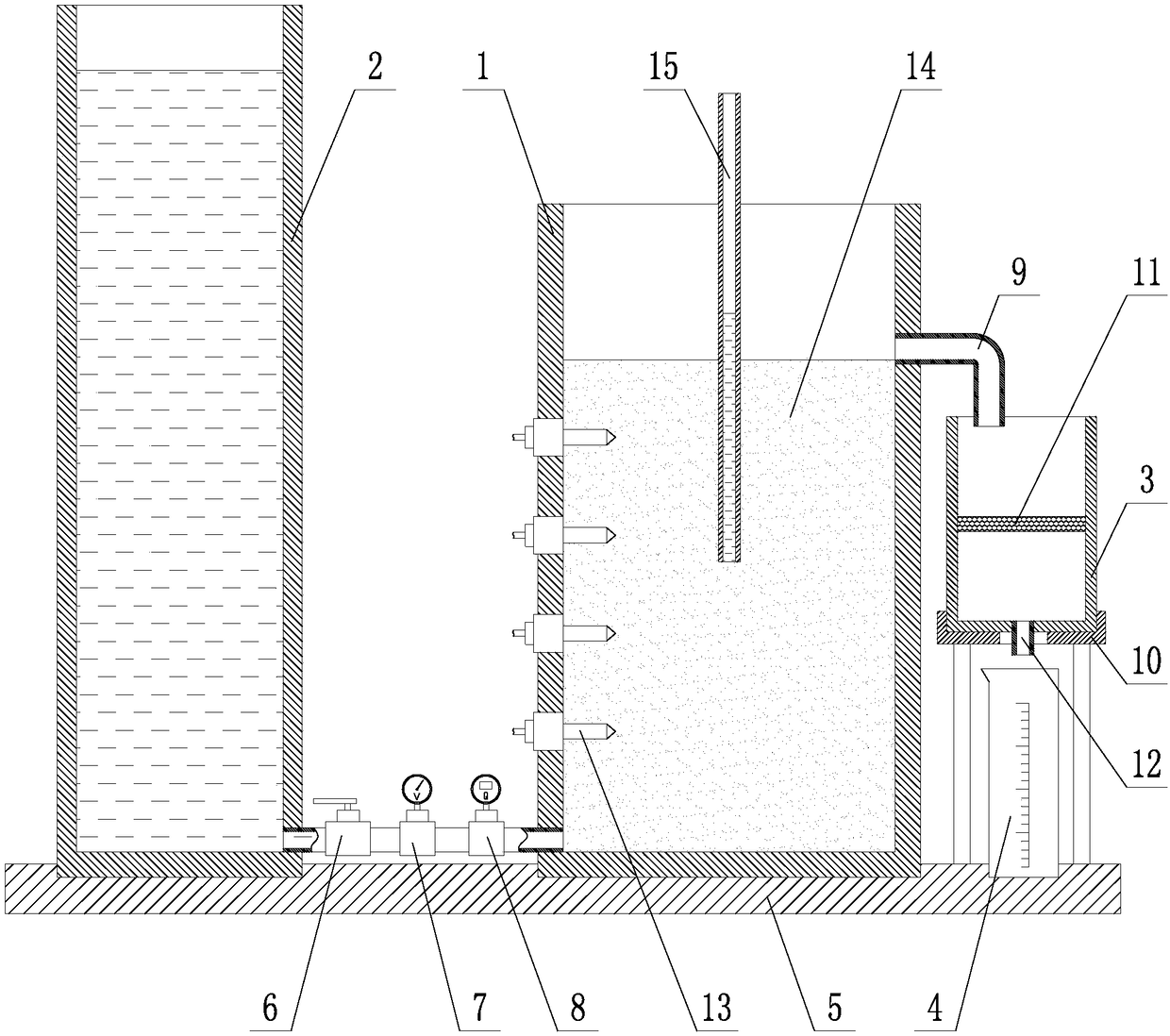

[0026] Such as figure 1 As shown, a sandy soil particle gradient fatigue liquefaction experiment device includes a sandy soil sample loading container 1, a water loading container 2, an overflow sandy soil collection container 3, an overflow water collection measuring cup 4 and a base 5; the sandy soil sample Both the loading container 1 and the water loading container 2 are fixedly placed on the base 5 through the countersunk holes on the upper surface of the base 5, the bottom of the water loading container 2 is provided with a water outlet hole, and the bottom of the sand sample loading container 1 is provided with a water inlet hole, the water inlet hole of the sand sample loading container 1 and the water outlet hole of the water loading container 2 are connected through a pipeline, and a regulating valve 6, a flow rate meter 7 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com